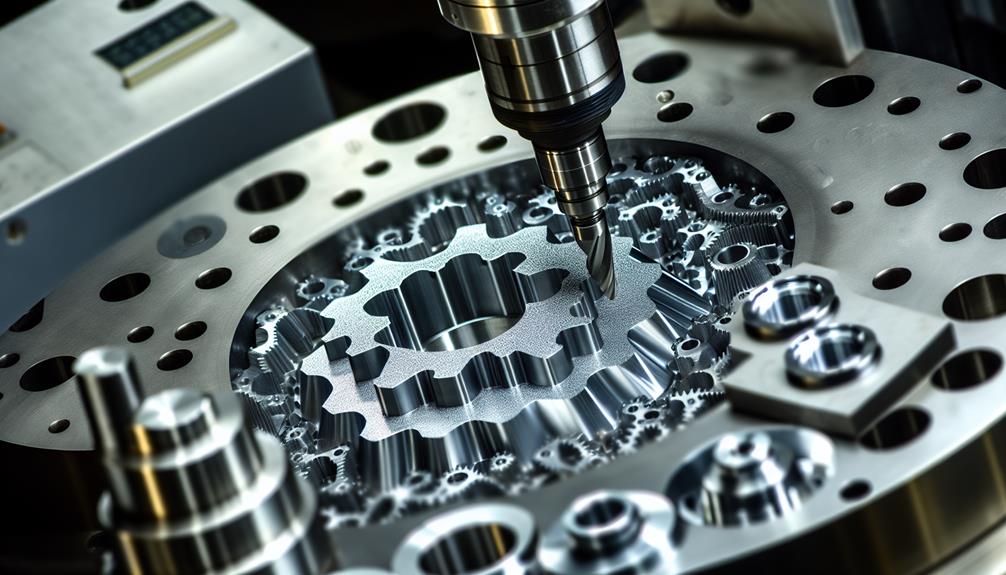

Why CNC Machining Parts Precision Matters in Modern Manufacturing?

In the realm of modern manufacturing, the precision of CNC machining parts is pivotal, serving as a cornerstone for industries where even a minor deviation can lead to significant repercussions. This exactness is not merely about adhering to design specifications; it is integral to ensuring the functionality, durability, and integration of components in complex systems, such as aerospace and medical devices. As manufacturers strive to push the boundaries of technology and innovation, the question arises: how does the relentless pursuit of precision influence the evolution of manufacturing practices and the competitive landscape? The implications are profound and merit closer examination.

Essential Role in Aerospace

CNC machining plays a crucial role in the aerospace industry by enabling the production of highly precise and complex components essential for aircraft performance and safety. In the sphere of aerospace advancements, precision engineering is not merely a requirement but a strict norm. The high-stakes nature of aviation demands components that meet exact specifications to ensure reliability and efficiency in all flight operations.

The integration of CNC technology in aerospace manufacturing allows for the meticulous creation of parts with tolerances that are often minuscule, and thus, critical to the successful function of various aerospace systems. These systems include engines, landing gear, and instrumentation, among others. Each component must flawlessly integrate with others to form a cohesive and safe operating machine.

Furthermore, the ability of CNC machines to consistently produce parts with high precision fosters innovation in aerospace design and materials. Engineers can experiment with complex shapes and new material combinations that were previously unattainable, pushing the boundaries of aerospace technology and enhancing the overall capabilities of aircraft.

Automotive Industry Standards

The automotive industry imposes stringent standards that ensure the safety, performance, and durability of CNC machined parts. Safety compliance protocols are critical in maintaining rigorous manufacturing practices that meet or exceed regulatory requirements.

Performance enhancement techniques and durability testing methods further refine CNC parts to withstand the demanding conditions of automotive operation.

Safety Compliance Protocols

Adhering to rigorous safety compliance protocols is essential for ensuring that CNC machined parts meet automotive industry standards. Ensuring workplace safety and systematic equipment maintenance are foundational elements in this context. Strict adherence to these protocols not only protects the workforce but also guarantees that the machinery used is always at peak performance, thus ensuring consistent quality in parts production.

The importance of regulatory compliance cannot be overstressed. Each component produced via CNC machining must pass through stringent quality control processes to meet or exceed the established automotive industry standards. This level of scrutiny is crucial because any failure in component performance can lead to dire consequences in automotive safety and efficacy.

Regular audits and inspections are a norm in the industry, serving as a double-check mechanism to uphold these high standards.

Performance Enhancement Techniques

Building on the foundation of strict safety and quality standards, performance enhancement techniques in the automotive industry focus on optimizing the efficiency and longevity of CNC machined parts. These methods include advanced material optimization and innovative surface finishing technologies, which are critical in meeting the demanding tolerances and specifications required by the industry.

Material optimization involves selecting the right materials that provide the necessary strength, durability, and resistance to various stressors while maintaining cost-effectiveness. This careful selection process ensures that the parts can withstand the rigorous demands of automotive applications without compromising performance.

Furthermore, surface finishing techniques such as anodizing, plating, and polishing not only enhance the appearance of these components but also significantly improve their corrosion resistance and fatigue life.

Additionally, managing tool wear and optimizing cutting speeds are crucial for maintaining the precision of CNC machined parts. Excessive tool wear can lead to dimensional inaccuracies and subpar surface quality, which are unacceptable in safety-critical applications. By monitoring and adjusting cutting speeds, manufacturers can minimize tool wear, extend tool life, and ensure consistent product quality.

These practices not only enhance the performance of the parts but also contribute to overall manufacturing efficiency.

Durability Testing Methods

Durability testing methods in the automotive industry set rigorous benchmarks to ensure CNC machined parts can endure under harsh operational conditions. These methodologies, crucial for assessing the reliability and longevity of components, are systematically applied through both destructive and non-destructive testing (NDT).

Destructive testing deliberately stresses parts to their breaking points. This process involves applying controlled, escalating forces to components such as gears, shafts, and casings until they fail. The data collected from these failures helps engineers understand the maximum limits of part durability and identify potential areas for material or design enhancements.

Conversely, non-destructive testing provides vital insights without damaging the parts. Techniques such as ultrasonic testing, magnetic particle inspection, and X-ray imaging allow inspectors to detect internal and surface flaws like cracks, voids, and inclusions. This form of testing is invaluable for ongoing quality control and ensuring parts meet stringent safety standards without compromising their integrity.

Implementing both testing methods gives manufacturers a comprehensive view of product performance. This dual approach ensures that every CNC machined part not only fits precisely but also performs reliably over time, thus offering automotive industry stakeholders a high degree of control over product lifecycle and safety.

Advances in Consumer Electronics

Innovation in CNC machining parts has significantly enhanced the functionality and design of consumer electronics. This precision technology allows for the production of intricate components necessary for the advanced features of smart technology and wearable devices. By ensuring high accuracy in the manufacturing process, CNC machining supports the integration of complex circuitry and micro-mechanical systems, which are crucial for the performance and reliability of these sophisticated gadgets.

The ability to produce precisely engineered parts is vital to the consumer electronics sector, where there is a constant demand for smaller, more efficient devices. CNC machining facilitates the miniaturization trend, enabling the creation of compact and portable electronics that fit seamlessly into daily life. For instance, the precision in machining helps in developing thin yet durable frames for smartwatches, enhancing both their aesthetic appeal and functionality.

Moreover, the high standards of precision in CNC machining contribute to the longevity and durability of devices, a critical factor for consumers who invest heavily in high-tech electronics. This control over component quality not only meets but often exceeds consumer expectations, reinforcing brand loyalty and driving the innovation cycle forward in this dynamic industry.

Impact on Medical Devices

CNC machining consistently plays a crucial role in the development and manufacturing of medical devices, ensuring high precision and adaptability in their production. The precision and reliability provided by CNC machining are paramount, particularly when it comes to fabricating critical medical components such as surgical instruments and prosthetic limbs. The meticulous requirements in medical device manufacturing demand not only precision but also a high degree of repeatability and quality assurance, which CNC technology adeptly provides.

Here are three key impacts of CNC machining on medical devices:

- Enhanced Precision for Surgical Instruments: CNC machining allows for the production of surgical instruments with exact dimensions and tolerances that are crucial for successful surgeries. This precision ensures tools perform reliably under stringent medical standards.

- Customization of Prosthetic Limbs: The adaptability of CNC machining facilitates the customization of prosthetic limbs, accommodating the unique needs of patients. This results in better patient outcomes and improved quality of life.

- Rapid Prototyping: CNC machining accelerates the prototyping phase of medical device development, enabling quicker iterations and testing. This rapid prototyping capability significantly shortens the time to market for new devices, ensuring that innovative solutions reach patients faster.

Boosting Energy Sector Efficiency

Precision machining is revolutionizing the energy sector by enhancing the efficiency and durability of essential components. By leveraging innovative materials and advanced CNC technology, manufacturers are able to produce parts with exceptional accuracy and tolerance levels. This not only contributes to energy conservation strategies by minimizing waste and energy consumption during production but also extends the lifespan and reliability of components used in energy systems, from wind turbines to solar panels.

The integration of precision-machined parts directly correlates with operational cost reduction. High-performance components that fit perfectly and function efficiently reduce the need for frequent replacements and extensive maintenance, thereby optimizing maintenance schedules and costs. This is critical in the energy sector where downtime or failures can result in significant financial losses and reduced energy output.

Furthermore, the use of durable and advanced materials in CNC machining allows for the development of components that can withstand harsh environments and variable loads typical in energy production settings. This resilience enhances component life and supports sustainable energy production, aligning with broader environmental goals and regulatory compliance.

In essence, the precise capabilities of CNC machining enable significant advancements in the energy sector, fostering more resilient and cost-effective operations.

Enhancing Military Equipment Reliability

Precision in CNC machining plays a pivotal role in enhancing the reliability of military equipment by adhering to stringent quality standards. This adherence significantly decreases the likelihood of equipment failures, thus maintaining operational integrity in critical situations.

Furthermore, improved manufacturing precision directly contributes to enhanced combat readiness, ensuring forces are equipped to perform at their highest capacity.

Stringent Quality Standards

Stringent quality standards are imperative for ensuring the reliability and performance of military equipment components machined using CNC technology. The precision afforded by CNC machining is foundational in manufacturing components that must meet the highest levels of durability and functionality. Adhering to these stringent standards is not only a matter of maintaining equipment integrity but also a critical factor in safeguarding lives.

In the realm of military applications, the following points illustrate why maintaining such high-quality standards is crucial:

- Manufacturing Efficiency: Precision CNC machining streamlines production processes, allowing for the consistent output of parts that meet exact specifications. This efficiency reduces waste and increases the speed at which equipment can be delivered and deployed.

- Material Selection: Choosing the right materials is essential for ensuring that each component can withstand extreme conditions and perform reliably. Advanced materials combined with precise machining lead to superior product quality.

- Industry Regulations and Product Innovation: Compliance with rigorous industry standards ensures that all machined components contribute to the overall reliability of military equipment. Innovations in product design and manufacturing techniques continually raise these standards, driving improvements in both performance and safety.

Decreased Equipment Failures

Utilizing CNC machining significantly reduces the likelihood of equipment failures, thereby enhancing the reliability of military hardware. Precision in manufacturing is not merely about adhering to specifications; it's about ensuring that every component functions optimally under the most demanding conditions. This meticulous attention to detail directly translates into fewer mechanical and operational issues, which is crucial for maintaining the operational integrity of military equipment.

The integration of CNC technology in the manufacturing process also boosts production efficiency. By automating the fabrication of parts, manufacturers can achieve a higher output rate while maintaining strict quality control. This means that equipment can be deployed faster, and maintenance schedules can be better predicted, minimizing downtime and enhancing overall operational readiness.

Moreover, the precision of CNC machining aids in the longevity of parts. This reduces the frequency and need for extensive equipment maintenance, saving time and resources. The ability to produce parts that precisely fit without the need for adjustments ensures that the equipment maintains its functionality over time, leading to a decrease in the likelihood of failures. This reliability is essential for military applications where equipment performance can directly influence mission outcomes.

Improved Combat Readiness

Enhanced combat readiness is directly supported by the reliability improvements offered by CNC machining in military equipment production. When military units deploy, the reliability of their equipment becomes a critical factor that can significantly influence combat effectiveness. Therefore, the precision manufacturing of parts using CNC technology is vital as it ensures equipment reliability and operational readiness.

This improved reliability plays a crucial role in several ways:

- Reduced Equipment Malfunction: CNC machining produces parts with extreme accuracy, which reduces the likelihood of malfunctions in the field. This directly impacts the performance of military operations, where every second counts.

- Enhanced Maintenance Cycles: High-precision parts have a longer lifespan and require less frequent replacement or repair. This predictability in maintenance schedules allows military forces to plan operations without the fear of unexpected equipment failures.

- Rapid Response Capability: With reliable equipment, military units can respond more swiftly and effectively to tactical situations. This readiness is essential for maintaining superior combat positions and can decisively influence the outcome of engagements.

Frequently Asked Questions

How Does Humidity Affect CNC Machining Accuracy?

Humidity fluctuations can significantly impact CNC machining accuracy by affecting material dimensions and machining tolerances. Controlling ambient humidity is crucial to maintain the precision required for high-quality and consistent manufacturing outputs.

What Is the Cost Difference Between CNC and Manual Machining?

CNC machining typically costs 50% more upfront than manual machining, but offers significant savings through efficiency. Cost analysis shows CNC's superior precision and speed justify the initial investment for high-volume production needs.

Can CNC Machines Use Recycled Materials Effectively?

CNC machines can effectively use recycled materials, maintaining high efficiency. This capability allows manufacturers to control costs and reduce waste, aligning with sustainability goals while preserving the precision and quality of the final product.

How Often Do CNC Machines Require Maintenance?

CNC machines require regular maintenance to minimize downtime and enhance longevity. Preventative measures should be scheduled based on usage intensity, typically ranging from monthly to quarterly, ensuring operational efficiency and control over production processes.

Are CNC Machined Parts Generally More Sustainable?

CNC machined parts often promote material sustainability and reduce environmental impact by maximizing resource efficiency and minimizing waste, aligning with sustainable manufacturing practices desired for greater control over production and ecological footprints.

Mikehardware-your trusted custom metal cnc machined parts manufacturer

In conclusion, precision in CNC machining plays an indispensable role in enhancing the quality and reliability of products across various industries.

A notable statistic underscores its significance: in the aerospace sector, a mere 0.0001-inch deviation in component accuracy can lead to catastrophic failures.

Hence, achieving high precision is paramount for ensuring safety, compliance with stringent standards, minimizing waste, and fostering innovation in manufacturing processes, thereby maintaining global competitiveness and customer trust.

At Dongguan Mike Hardware Co., Ltd., precision engineering meets innovation, delivering impeccable CNC product manufacturing solutions. Explore our array of customized fasteners, screws, and coatings, ensuring your projects excel in performance, precision, and quality.

Contact us for a free quote of your ideal metal cnc machined parts.