Why Bolt Head Is Hexagonal

Hexagonal bolt heads have long fascinated engineers and manufacturers due to their unique shape. The origins of this hexagonal design can be traced back to early industrial eras, where the need for a secure and efficient fastening solution became paramount.

This article aims to delve into the historical origins, advantages in manufacturing processes, scientific principles underlying the hexagonal bolt head's effectiveness, comparisons with alternative shapes, and practical applications across industries.

By exploring these aspects, we hope to shed light on why the hexagonal bolt head remains an integral component in modern engineering practices.

Key Takeaways

- Hexagonal bolt heads emerged during the Industrial Revolution in the 18th and 19th centuries, providing increased stability, improved grip, and suitability for high torque applications.

- The standardized design of hexagonal bolt heads allowed for easier mass production, interchangeability, and reduced costs.

- The symmetrical polygon shape of hexagonal bolt heads allows for easier gripping and turning, improved load distribution, precise alignment during assembly, and enhanced mechanical properties.

- Hexagonal bolt heads offer better grip, torque transmission, space utilization, strength, and durability compared to other shapes, making them widely used in industries such as automotive, construction, aerospace, and machinery.

1. Historical Origins of Hexagonal Bolt Heads

The historical origins of hexagonal bolt heads can be traced back to their implementation in early industrial engineering practices. The use of bolts and screws dates back centuries, with various head designs being used throughout history. However, it was during the Industrial Revolution in the 18th and 19th centuries that the hexagonal bolt head emerged as a key innovation.

The adoption of hexagonal bolt heads in manufacturing was driven by several factors. First and foremost, the six-sided shape provided increased stability and improved grip when compared to other head designs such as square or round heads. This made them ideal for applications that required high torque or heavy tightening forces.

Furthermore, the standardized design of hexagonal bolt heads allowed for easier mass production and interchangeability among different components. This facilitated assembly line processes and reduced costs associated with manufacturing and maintenance.

In addition, the use of hexagonal wrenches or sockets to tighten or loosen hexagonal bolts provided greater control over torque application, ensuring consistent results across various applications.

Overall, the historical implementation of hexagonal bolt heads in early industrial engineering practices was driven by their superior stability, ease of mass production, interchangeability, and controllability. These advantages laid the foundation for their continued widespread use in modern manufacturing processes.

2. Advantages of Hexagonal Bolt Heads in Manufacturing

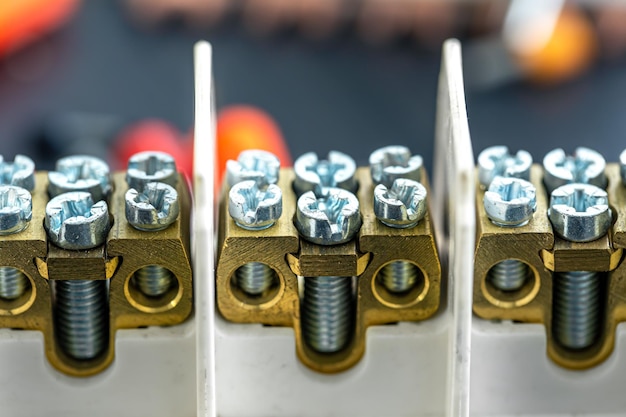

One advantage of hexagonal bolt heads in manufacturing is their ability to provide a secure and reliable grip for tools during installation or removal. The six-sided shape of the bolt head allows for multiple points of contact between the tool and the bolt, increasing the torque that can be applied without slipping. This ensures that the force exerted on the bolt is efficiently transferred to either tighten or loosen it. Additionally, the flat surfaces of the hexagonal shape make it easier to apply even pressure across all sides, minimizing the risk of stripping or damaging the bolt head.

The use of hexagonal bolt heads also offers practical benefits in terms of manufacturing efficiency. Their standardized design allows for easy identification and selection, reducing time-consuming errors during assembly processes. Furthermore, hexagonal bolts are compatible with a wide range of tools such as wrenches, sockets, and pliers, making them versatile options for various applications.

Understanding why hexagonal bolt heads have these advantages requires delving into their underlying science. By examining factors such as frictional forces between surfaces and mechanical principles related to torque transmission, we can gain insight into how this simple geometric shape optimizes functionality in manufacturing settings.

3. The Science Behind Hexagonal Bolt Heads

Examining the underlying science of hexagonal bolt heads reveals insights into how this geometric shape optimizes functionality in manufacturing settings. The hexagonal shape is a polygon with six equal sides and angles, creating a symmetrical structure. This symmetry provides several benefits for bolt heads.

Firstly, it allows for easier gripping and turning of the bolt using standard tools such as wrenches or sockets. The six-sided design distributes force evenly along each side, reducing the likelihood of slipping or stripping during tightening or loosening operations.

Moreover, the geometry of hexagonal bolt heads enhances their mechanical properties. The flat surfaces formed by each side create more contact points between the head and its mating surface on the object being fastened. This increased contact area improves load distribution and prevents localized stress concentration, leading to enhanced strength and resistance to shear forces.

Additionally, the utilization of internal angles within the hexagonal shape allows for efficient engagement with corresponding nuts or threaded holes. The corners facilitate precise alignment during assembly, reducing errors that can occur with other shapes like square or round heads.

Comparing hexagonal bolt heads to other shapes brings forth further understanding of their unique advantages in manufacturing applications without explicitly stating 'step.'

4. Comparing Hexagonal Bolt Heads to Other Shapes

Comparing hexagonal bolt heads to other shapes provides valuable insights into their distinct advantages in manufacturing applications. When evaluating different shapes, the hexagonal bolt head stands out due to its unique characteristics. Here are four reasons why hexagonal bolt heads are preferred in various industries:

1. Efficient torque transmission: The six-sided design of a hexagonal bolt head allows for better grip and torque transmission than other shapes. This makes it easier to tighten or loosen the bolt without slipping, reducing the risk of accidents and ensuring a secure fastening.

2. Space utilization: Hexagonal heads have a compact shape that optimizes space utilization. Compared to square or round heads, they require less clearance and can be tightly packed together, making them ideal for applications where space is limited.

3. Robustness: Hexagonal bolts offer excellent strength and durability due to their larger contact area with wrenches or sockets compared to other shapes like Phillips or slotted heads. This increased surface area distributes force more evenly, minimizing the risk of rounding off corners or damaging the bolt head.

4. Standardization: Another advantage of hexagonal bolts is their wide availability and standardized sizes across industries globally. This facilitates interchangeability, simplifies inventory management, and reduces costs associated with specialized tools.

Understanding these advantages enables engineers and manufacturers to make informed decisions when selecting fasteners for specific applications within their respective fields. In the following section, we will explore practical applications of hexagonal bolt heads without explicitly mentioning 'step'.

5. Practical Applications of Hexagonal Bolt Heads

Practical applications of hexagonal bolt heads are found in a wide range of industries due to their efficient torque transmission, space utilization, robustness, and standardization.

The hexagonal shape of the bolt head provides multiple advantages that make it suitable for various applications. Firstly, the six-sided design allows for efficient torque transmission. This means that when force is applied to the bolt head during tightening or loosening, it is evenly distributed across all sides of the hexagon, reducing the risk of slippage or stripping.

Additionally, the compact nature of hexagonal bolt heads makes them ideal for situations where space is limited. Their shape enables them to fit into tight spaces without compromising their functionality or strength.

The robustness of hexagonal bolt heads also contributes to their practical applications. Hexagonal bolts are designed to withstand high levels of stress and remain securely fastened even under extreme conditions. This reliability is crucial in industries such as construction, automotive manufacturing, aerospace engineering, and machinery assembly where safety and durability are paramount.

Furthermore, hexagonal bolt heads have become standardized across many industries. This standardization ensures interchangeability between different components and facilitates ease of assembly and maintenance processes. It also simplifies inventory management by allowing companies to stock a single type of wrench or socket for various applications.

Mikehardware- your trusted bolts supplier

In conclusion, the hexagonal shape of bolt heads has a rich historical background and a multitude of practical advantages in manufacturing.

Its symmetrical design allows for easy gripping and tightening, making it highly efficient.

Furthermore, its six-sided structure provides stability and prevents the bolt from loosening over time.

Like a sturdy fortress guarding against intrusion, the hexagonal bolt head is an essential component in various applications across industries, ensuring strong connections that withstands the test of time.