Top Industries That Benefit From Custom Bolts and Screws

In the realm of industrial applications, custom bolts and screws play an indispensable role across a spectrum of sectors, each with its unique demands and challenges. The aerospace and aviation industry, for instance, relies on these precision components for both safety and functionality, demanding the highest standards of durability and performance under extreme conditions. Similarly, in automotive manufacturing, custom bolts are essential for ensuring the reliability and longevity of vehicles through rigorous use. While these examples highlight the critical nature of specialized fastening solutions, one might ponder how such seemingly minor components can precipitate major advancements in technology and construction. What further implications could these tailored fasteners have across other technologically intensive industries?

Key Takeaways

- Aerospace and Aviation: Custom bolts ensure aircraft performance and safety by withstanding extreme conditions and high temperatures.

- Automotive Manufacturing: Enhances vehicle reliability and production efficiency through precision assembly and durable, corrosion-resistant fasteners.

- Construction and Architecture: Specialized fasteners improve structural integrity and longevity, crucial for safety and aesthetic design in buildings.

- Electronics and Technology: Precision in design and size adaptability are vital for the reliability of advanced technological devices.

- Marine and Offshore: Custom screws and bolts offer enhanced corrosion resistance, crucial for durability in harsh underwater environments.

Aerospace and Aviation

In the aerospace and aviation industries, custom bolts and screws are crucial for ensuring the integrity and functionality of aircraft components. These specialized fasteners are designed to meet exacting standards, essential for maintaining the safety and performance of aircraft in demanding environments.

Material selection plays a pivotal role in this context, as the choice of materials directly influences the weight of the aircraft. The drive for weight reduction—critical for fuel efficiency and payload capacity—requires that each component be as lightweight as possible without compromising on strength or integrity.

Furthermore, aerospace fasteners must withstand extreme conditions, including high temperatures and potential corrosion. The environments encountered at high altitudes or during high-speed flight expose aircraft components to conditions that can severely degrade typical materials.

Engineers, therefore, opt for materials that offer high corrosion resistance and can maintain their mechanical properties even under high thermal stress. This necessitates a meticulous approach in the design and manufacturing phases, ensuring that every bolt and screw not only fits perfectly but also performs reliably over time.

Automotive Manufacturing

In the realm of automotive manufacturing, the selection of custom bolts and screws is critical for enhancing precision assembly and ensuring the durability of vehicle components.

These specialized fasteners are designed to meet exact specifications that contribute to the overall performance and longevity of automobiles.

Precision Assembly Enhancements

Precision assembly enhancements in automotive manufacturing significantly improve the efficiency and reliability of vehicle production. By integrating custom bolts and screws specifically designed for particular applications, manufacturers can achieve higher quality control standards and efficiency improvements. These specialized fasteners are engineered to fit unique assembly requirements, reducing the risk of errors and inconsistencies during production.

Custom bolts and screws contribute to streamlined assembly processes by ensuring that components fit perfectly, which minimizes the time spent on adjustments and reworks. This precision directly correlates with enhanced production speeds and better resource utilization, crucial for staying competitive in the dynamic automotive market.

Moreover, the use of impeccably tailored fasteners aids in maintaining the integrity of critical connections, crucial for the assembly of complex automotive systems.

Such advancements in fastening technology also enable manufacturers to exert greater control over the assembly environment. With better control, they can more effectively manage the variables that impact production quality and efficiency. This capability is vital for automakers striving to meet stringent industry standards while responding swiftly to market demands and technological changes.

Durability in Vehicle Components

Durability of vehicle components is vital in automotive manufacturing, as it ensures long-term reliability and safety of the vehicles. Custom bolts and screws, designed specifically for the automotive industry, contribute significantly to this durability. They are crafted to meet exact specifications that standard fasteners cannot always guarantee, thus providing an essential advantage in creating dependable vehicle components.

Custom fasteners are developed with several key characteristics in mind, tailored to enhance component longevity and performance:

- Corrosion Resistance: Essential for parts exposed to harsh environments; prevents degradation and extends the life of vehicle components.

- High Tensile Strength: Ensures that fasteners can withstand the intense forces and stresses typical in automotive operations without breaking.

- Precision Fit: Reduces the risk of loosening under vibration, a common issue in vehicles, thereby enhancing safety.

- Heat Resistance: Important for components near the engine or exhaust systems, where temperatures can be extreme.

- Custom Coatings: Options like zinc, nickel, or chromium add extra protection against wear and corrosion, while also providing a cleaner appearance.

For those who demand control over every aspect of vehicle manufacturing, opting for custom bolts and screws can significantly influence the quality and resilience of the final product.

Construction and Architecture

In the realm of construction and architecture, custom bolts and screws play pivotal roles. Particularly in enhancing structural integrity and integrating aesthetic design. These specialized fasteners are designed to meet specific demands, ensuring that buildings not only remain safe and sturdy but also visually appealing.

Their tailored characteristics allow architects and builders to achieve both durability and design excellence, crucial for modern construction standards.

Structural Integrity Enhancement

Custom bolts and screws play a critical role in enhancing the structural integrity of buildings and architectural designs. These specialized fasteners are designed to meet specific requirements that standard bolts and screws cannot fulfill, ensuring a higher level of performance in critical structural applications.

The choice of materials and the engineering behind these bolts and screws are crucial for maintaining the longevity and safety of structures.

Key benefits include:

- Material Compatibility: Custom bolts ensure a perfect match with the materials they join, preventing issues such as galvanic corrosion.

- Corrosion Resistance: Enhanced treatments and coatings are applied to resist environmental degradation, crucial for outdoor and harsh environments.

- Load Distribution: Engineered to distribute stress evenly, reducing the risk of structural failures.

- Precision Fit: Custom dimensions achieve a precise fit, eliminating movement and enhancing joint stability.

- Longevity: Durable materials and superior manufacturing extend the lifespan of both the fasteners and the structures they secure.

Aesthetic Design Integration

Enhancing architectural aesthetics, custom bolts and screws are meticulously designed to blend seamlessly into modern construction projects, maintaining visual integrity while providing essential functionality. These specialized fasteners are not just utilitarian; they are pivotal in defining the visual and tactile qualities of architectural elements. Architects and designers leverage the unique capabilities of custom bolts and screws to ensure that every aspect of their construction not only meets structural needs but also complements the overall design ethos.

In the realm of high-end construction and bespoke architecture, aesthetic considerations are paramount. Custom bolts and screws in fashion-forward projects, for instance, serve as both functional components and design accents. These elements offer a dual purpose by reinforcing structural integrity while enhancing visual appeal. Similarly, aesthetic bolts in furniture not only secure pieces with reliability but also contribute to the design narrative, allowing creators to impose a signature style that commands control and exudes precision.

The ability to customize such hardware elements empowers architects and designers to maintain a strict adherence to their vision, ensuring that every joint, fixture, and finish reflects the intended aesthetic without compromise. Thus, custom bolts and screws are indispensable tools in the crafting of both functionally sound and visually stunning architectural works.

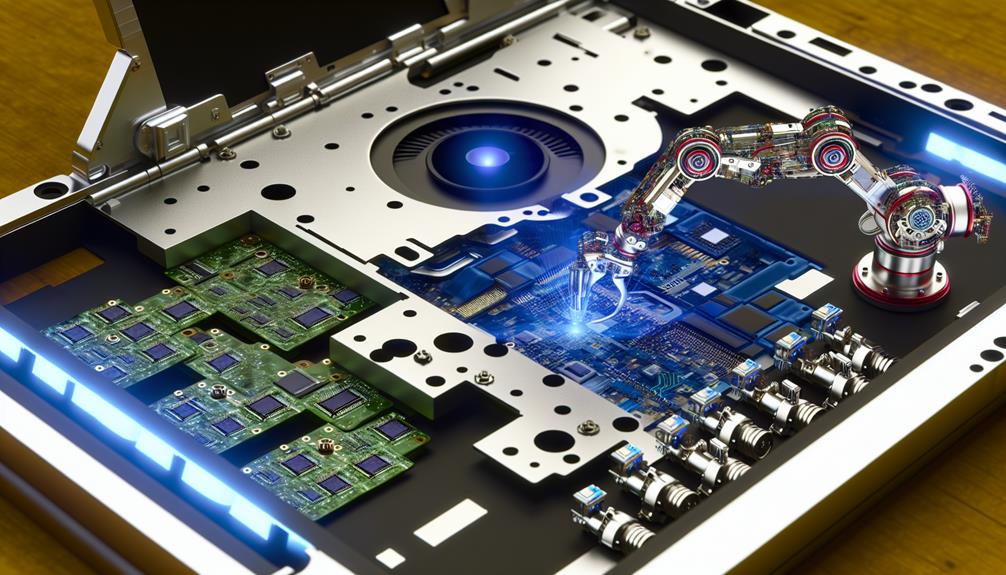

Electronics and Technology

Precision-engineered screws and bolts are integral to the assembly and durability of electronic devices. The production of miniature electronics and smart devices heavily relies on the utilization of customized fastening solutions to meet specific requirements. These components ensure that each device can withstand regular use without failure, thereby extending its operational life and maintaining performance standards. Custom screws and bolts provide the necessary precision and reliability demanded by the electronics industry.

Here are key advantages of custom bolts and screws in electronics and technology:

- Size Adaptability: Customization allows for the creation of miniature fasteners ideal for compact and intricate electronic assemblies.

- Material Selection: Engineers can select materials that enhance conductivity, resist corrosion, and provide required strength.

- Design Precision: Tailor-made designs ensure perfect fits and avoid issues like electromagnetic interference in sensitive devices.

- Enhanced Reliability: Custom fasteners are designed to meet exact tolerances, minimizing the risk of component failure.

- Innovative Solutions: Addressing unique challenges such as heat dissipation or non-magnetic requirements with specialized screws and bolts.

This tailored approach not only elevates the quality and functionality of electronic products but also empowers manufacturers with greater control over the final output, ensuring superior performance and customer satisfaction.

Marine and Offshore

In marine and offshore environments, the demand for durable and corrosion-resistant custom bolts and screws is particularly high to ensure the safety and longevity of structures exposed to harsh oceanic conditions. These specialized fasteners are crucial in constructing and maintaining everything from ships and submarines to offshore drilling platforms and underwater pipelines. The unique properties of these custom bolts and screws enable them to withstand the relentless assault of salty seawater, preventing the rapid deterioration that standard fasteners would suffer.

Corrosion resistance is not merely a desirable attribute but a stringent requirement in these settings. Materials such as titanium, stainless steel, and bronze are commonly employed to achieve this. Each material is selected based on its strength, durability, and resistance to the corrosive underwater environment, ensuring that the integrity of the structure remains uncompromised over time.

Underwater applications pose additional challenges as they require fasteners that can not only resist corrosion but also handle extreme pressures and temperatures. The development of such custom solutions allows for enhanced control over project outcomes, ensuring operational reliability and safety. This capability is vital for minimizing risks in an industry where equipment failure can have severe consequences, including environmental damage and significant financial losses.

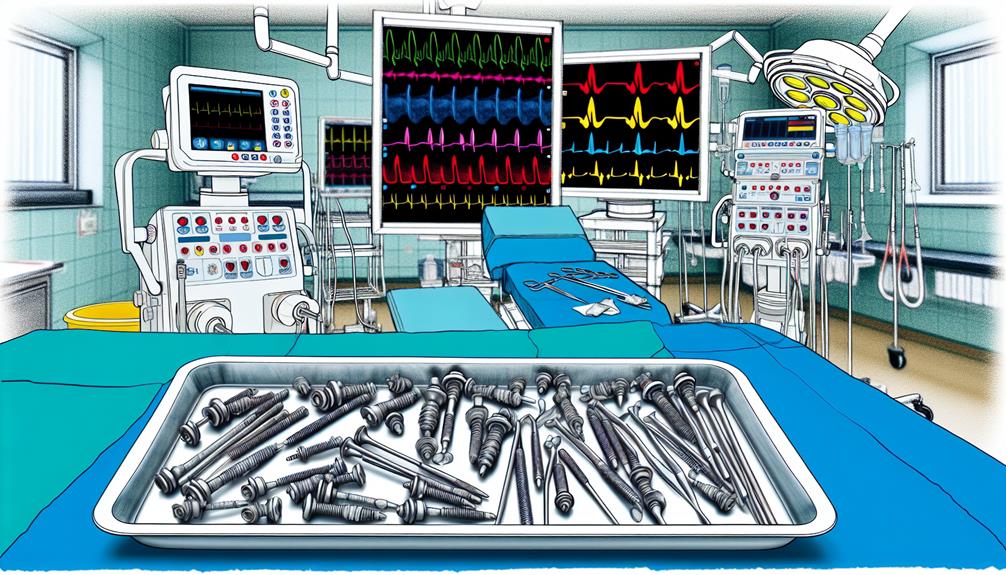

Medical Devices and Equipment

As with marine applications, the production of medical devices and equipment necessitates custom bolts and screws that meet stringent standards for hygiene, strength, and precision. In the medical field, every component in device manufacturing must adhere to exacting standards, as even the smallest deviation can significantly affect outcomes. This is especially true in the creation of surgical instruments and prosthetic implants, where precision and innovation are paramount.

To understand the critical role of customized fastening solutions in this industry, consider the following points:

- Surgical Instruments: Custom screws are crucial for the exacting precision required in tools used during operations. Their reliability directly impacts the success of surgical procedures.

- Prosthetic Implants: Innovations in bolt and screw design enhance the functionality and lifespan of implants, improving patient outcomes.

- Sterilization Compatibility: Custom fasteners are designed to withstand repeated sterilization processes without degrading, ensuring ongoing safety and functionality.

- Material Compliance: Specific materials are required for medical applications to prevent reactions and ensure biocompatibility.

- Custom Specifications: Tailored designs cater to the unique needs of advanced medical equipment, allowing for enhanced control and precision in medical treatments.

Each of these factors underscores the necessity for bespoke solutions in the medical device industry, ensuring patient safety and the integrity of critical health technologies.

Frequently Asked Questions

How Do Seasonal Changes Affect Bolt Material Choice?

Seasonal changes significantly influence bolt material choice, as variations in temperature and humidity demand high material durability and minimal environmental impact to maintain control over structural integrity and functionality throughout different climatic conditions.

Can Custom Bolts Improve Energy Efficiency in Machines?

Custom bolts can enhance machine performance by optimizing component fit, potentially improving energy efficiency by up to 15%. Precise engineering affords tighter control over operational parameters, leading to more sustainable energy usage.

What's the Average Lifespan of a Custom Screw?

The average lifespan of a custom screw depends on its corrosion resistance and durability. Factors like cost-effectiveness and aesthetics also play roles, ensuring optimal performance and longevity in various controlled application environments.

Are There Recycling Practices for Used Custom Bolts?

Yes, recycling practices for used custom bolts exist, symbolizing sustainability initiatives. These practices empower industries to not only control waste but also champion environmental stewardship, aligning with broader goals of resource conservation and sustainability.

How Do Global Trade Policies Impact Bolt Prices?

Global trade policies, particularly trade tariffs, significantly influence bolt prices by impacting manufacturing costs and international supply chains. Adjusting these policies can either stabilize or increase costs, affecting procurement strategies across multiple industries.

Conclusion

In conclusion, custom bolts and screws are indispensable across various sectors, underpinning pivotal advancements and ensuring operational excellence.

Consider the Golden Gate Bridge, a marvel of construction, relying on approximately 600,000 custom rivets, analogous to bolts, for its structural integrity.

This example aptly symbolizes the foundational role that these bespoke components play in not only supporting monumental edifices but also in driving innovation and precision across diverse industries—from the depths of the ocean to the vastness of space.