Top 15 Fasteners Manufacturers in China

China stands as a global manufacturing powerhouse, and its prowess extends to the production of fasteners. Fasteners are integral components in various industries, including automotive, construction, aerospace, and more. If you're seeking reliable and high-quality custom metal part hardware solutions, China has a vibrant landscape of fasteners manufacturers to choose from. In this blog, we'll introduce you to the top 15 fasteners manufacturers in China. These companies have established themselves as leaders in the industry, delivering precision-engineered fasteners that meet international standards and cater to diverse applications. Let's delve into their expertise and capabilities, helping you make informed decisions for your metal hardware needs.

1.Gem-Year Industrial Co.,Ltd.

Gem-Year produces all kinds of high-quality products such as bolts, nuts, screws, drawn wire and other off-standard fasteners, which are according to GB, ANSI, DIN, UNI, JIS and ISO standards with yearly production output of 200,000 metric tons.

Gem-Year Industrial Co.,Ltd. established in November 1995, Gem-Year Industrial Co.,Ltd.is located at No.8, Gem-Year Rd., Economic Development Zone, Jiashan, Zhejiang Province, P.R.China.

Throughout the years, Both Gem-Year's management approaches of "Quality, Customer Satisfaction Pioneering Attitude" and business core values of "Honesty, Dedication, Teamwork Innovation" has continuously evolved based on the essences of both ancient Chinese Confucianism and western management philosophy.

Product Range: Our fasteners are used in high-speed railways, highways steel structures, electric appliances, furniture, electric power, automobiles, motorcycle, bicycle, engine, general machinery and others. Registered Capital The total register.

2.HISENER INDUSTRIAL CO., LTD.

In 2004, Hisener was founded in Haining, Zhejiang, China, as a threaded rods producer. Two years later, the company expanded its operations to include a full-range fastener distribution line. By 2010, Hisener had also established its own screws factory. Over the years, Hisener has solidified its reputation as one of the top global suppliers of screws and various fasteners, earning the trust of customers worldwide.

In response to the growing demand for diverse packaging solutions in the DIY market, Hisener took strategic steps in 2015. The company set up a state-of-the-art automated packing line facility and constructed a warehouse in Haiyan. By 2017, Hisener had relocated its packing lines and storage operations to a new, spacious 4000-square-meter facility in Haining. This move was part of an effort to enhance productivity and streamline operations alongside the screws factory.

In 2022, Hisener marked a significant milestone with the inauguration of a modern factory spanning 32000 square meters. This expansion greatly increased the company's production capacity, allowing it to meet the growing demands of its global clientele effectively.

Today, Hisener boasts an extensive product catalog comprising more than 4000 items, each available in various packaging options to cater to the evolving needs of its expanding customer base. Stringent production procedures and rigorous quality control measures are implemented for every product batch, ensuring that only top-quality products are delivered to customers. Hisener is proudly certified by ISO9001:2015, ISO45001:2018, and ISO14001:2015, in addition to holding ETA and CE certificates, further affirming its commitment to quality and excellence.

3.Dongguan Mike Hardware Co., Ltd.

Dongguan Mike Hardware Co., Ltd. serves as a trusted partner for CNC product manufacturing. Leveraging over a decade of industry experience and a skilled team of more than 50 professionals, they bring an impressive two decades of expertise to the forefront. Their comprehensive one-stop production solutions encompass everything from mold design to CNC processing and surface treatment. With a state-of-the-art facility and a workforce of over 350 proficient operators, they ensure the seamless execution of every project.

Backed by a team of 15 experienced mold designers, Dongguan Mike Hardware Co., Ltd. excels in providing personalized project follow-up supported by advanced 2D and 3D technology, resulting in an impressive 98% product completion rate. Their mold manufacturing team, boasting 15 years of experience, offers tailored project support and quick mold openings within a span of just 2-7 days, allowing clients to save costs without compromising quality.

Specializing in one-stop fastener solutions, Dongguan Mike Hardware Co., Ltd. offers a wide range of products, including special coating fasteners, ASTM/ASME standard material fasteners, special application fasteners, and CNC/machining parts. Their product portfolio encompasses non-standard screws, auto fasteners, special coating fasteners, and various types of standard screws, including machine screws, sheet metal screws, security screws, SEMS screws, thread-cutting screws, tapping screws, and thumb screws.

Choose Dongguan Mike Hardware Co., Ltd. for their industry expertise, cutting-edge facilities, and unwavering commitment to excellence. Trust them for precise, efficient, and professional CNC product manufacturing.

4.China Ningbo Taida Fastener Manufacture Co., Ltd.

Taida Fastener specializes in the production of stud bolts, threaded rods, bolts, and nuts. They offer a wide range of standards including DIN931, DIN933, DIN558, ASTM A325 hexagon head bolts, DIN934, DIN6923, DIN985, ASTM A 194 2H nuts, DIN960, DIN961, DIN6914, DIN7990, DIN7991, DIN912, DIN7985 screws, DIN975, DIN976, ASTM A 193 B7 threaded rods, as well as other AS, GB, ISO, BS, and JIS standards. Additionally, they are open to producing non-standard products to meet specific customer requirements.

With a commitment to maintaining the highest quality and service standards, they blend experience with cutting-edge manufacturing technology. Their products cater to the oilfield and various industrial markets. They offer a diverse range of sizes, spanning from M12 to M100 (1/2 inch to 4 inches) in diameter, and a variety of product grades including 4.8, 6.8, 8.8, 10.9, 12.9, B7, L7, and B7M. These products are crafted from materials such as 35#, 45#, 40Cr, 35CrMoA, 42CrMoA, 25Cr2MoVA, 20MnTiB, and various grades of stainless steel.

Their product applications encompass machinery, construction, bridges, petrochemicals, and more. While their products have gained significant popularity within China, they have also made a mark on the global stage, reaching markets in Europe, North America, the Middle East, Japan, and beyond.

Operating on the principle of "quality as the eternal foundation and an unwavering pursuit of integrity," China Ningbo Taida Fastener Manufacture Co., Ltd. is dedicated to delivering consistent quality and exceptional service to their clients. They extend a warm welcome to domestic and international partners for enduring cooperation and growth.

5.Shanghai Jianxin Hardware Co.,Ltd.

Shanghai Jianxin Hardware Co., Ltd. serves as the sales agent for Tianbao Fastener in Shanghai. They have a global market presence, extending their reach to over 55 countries and regions worldwide, with a client base comprising more than 200 diverse customers. With a steadfast commitment to their business principle of prioritizing quality, they aim to provide superior service to their customers, leveraging their extensive industry experience.

Their primary product offerings encompass a wide range, including Hex nuts (DIN934, DIN555, ISO4034, DIN6915, ASTM 2H, IFI D-6, A563), Flange nuts (DIN6923), Nylon insert nuts (DIN985), Wheel nuts, Hex bolts (DIN931, DIN931, ISO4014, ISO4017, DIN6914), Socket hex bolts (DIN912), T-Nuts, Washers (DIN125, DIN127, DIN6916), Thread rods (DIN975), Machine screws, Wood screws, Drywall screws, and Chipboard screws. These products adhere to international standards such as DIN, ANSI, BS, JIS, GB, and ISO.

Shanghai Jianxin Hardware Co., Ltd. offers an array of strength grades, encompassing CLASS 6, CLASS 8, CLASS 10, 2H, and HV10 for Nuts, as well as CLASS 4.8, CLASS 6.8, CLASS 8.8, CLASS 10.9, and HV 10.9 for bolts. They provide a variety of surface finishes, including black oxide, zinc plate, phosphate, hot dip galvanized, Dacromet, and others. The raw steel materials utilized in their manufacturing processes include SWRCH35K, 10B21, ML08AL, Q195, Q235, Q215, and 40Cr.

Shanghai Jianxin Hardware Co., Ltd. distinguishes itself by offering a comprehensive product range, the flexibility to provide customized headmarks, labels, packages, and non-standard products, facilitating a convenient one-stop shopping experience for their clientele.

6.Ningbo Fastenwell Metal Technology Co., Ltd.

FASTENWELL, a prominent fasteners manufacturer in China, boasts a 15-year track record of excellence in bolts and screws production. Their annual output, which exceeds 5000 tons, encompasses a diverse range of fasteners, with a notable emphasis on hex bolts, structural bolts, and studs. The inception of FASTENWELL can be traced back to 2006 when their visionary factory leader embarked on a mission to establish themselves as the preferred choice among fasteners manufacturers in China.

The comprehensive product portfolio offered by FASTENWELL includes hex bolts, such as hex cap screws DIN931, DIN933, and ISO4014, along with ISO4017, structural bolts A325, A490, and studs B7. They also provide an array of screws, encompassing machine screws, socket head cap screws, self-tapping screws, chipboard screws, among others. Moreover, FASTENWELL is well-equipped to customize specialty fasteners to exact specifications, either based on drawings or samples.

Years of unwavering commitment and customer support have fueled FASTENWELL's growth. They maintain both cold forging and hot forging production lines for bolts and studs, ensuring flexibility to meet customer orders. Quality is paramount, as all items undergo rigorous testing before shipment, with the issuance of 3.1 certificates in line with customer requirements.

Their clientele comprises a significant presence in the fastener industry, including wholesalers, contractors, traders, and manufacturers involved in diverse applications like construction, steel structures, oil and gas, automobiles, wind energy, marine, HVAC, and furniture. FASTENWELL's remarkable market reach extends to Asia, the Middle East, North and South America. For those seeking a dependable, long-term partnership with a trusted fasteners manufacturer in China, FASTENWELL stands as a compelling choice, consistently proving its worth.

7.Tong Ming Enterprise Co.,Ltd.

Tong Ming Enterprise was established in 1996 by the TONG group in the Jiaxing Economic Development Zone, Zhejiang Province, China. The Tong group is the international stainless steel fastener giant with the prominent "THE" and "TONG" head markings. The TONG group manufactures stainless steel fasteners with production bases in Malaysia, Thailand and China.

Tong Ming features the TONG group's premier production facilities. The 152,000 square meter production facility Tong Ming campus in China, utilizes the most modern imported equipment and manufacturing techniques. Tong Ming guarantees and stands 100% behind the quality of its products. The ubiquitous "THE" and "TONG" headmarks are renowned around the world for the quality it stands for.

8.Changshu Standard Parts Factory Co., Ltd.

Changshu Standard Parts Factory Co., Ltd., situated in Changshu High-tech Industrial Development Zone, Jiangsu Province, is a prominent player in China's fastener industry. Covering 500,000 square meters, with 250,000 square meters of built space and assets worth ¥1 billion, it employs 920 professionals. Recognized by the China Machinery Industry Federation, it is an independent import-export entity approved by the Ministry of Foreign Trade and Economic Cooperation, with overseas material processing capabilities.

The company boasts a robust product development system, securing quality certifications and accolades such as ISO 9001:2015 and CE certifications. Its state-of-the-art facilities house over 1,800 key equipment units, including 400+ fastener cold heading machines, with 50% sourced internationally. It features 14 heat treatment lines, producing 140,000 tons of high-strength bolts annually. Additionally, it possesses strong machining capabilities, spanning cold heading machine manufacturing, fastener mold production, mechanical parts processing, and tooling assembly.

"Dali brand" products are crafted from top-tier materials and managed via an ERP system. The product range encompasses bolts, screws, nuts, studs, assemblies, non-standard parts, and more, with an annual output capacity of 180,000 tons. These high-quality fasteners are exported to regions including the European Union, Japan, the Middle East, and Southeast Asia.

9.EAGLE METALMARE CO.,LTD.

Established in 1968, EAGLE METALMARE is a global leader in manufacturing high-strength screws of 12.9 grades. They specialize in hex socket screws, automotive components, and expansion screws, providing high-quality fastening solutions across industries. As a subsidiary of Hong Kong Fupeng Investment Co., EAGLE METALMARE integrates manufacturing, R&D, and sales in mainland China.

With 40+ years of innovation driven by customer needs and technology, EAGLE METALMARE remains at the industry forefront, known for a comprehensive range of high-quality products and "Serving Detail, Fastening the World" spirit.

Operating from two production bases in Dongguan and Kunshan, covering 130,000+ sq. meters, the company employs advanced equipment, holds ISO certifications, and exports products to Europe, the USA, Japan, and Southeast Asia.

With 60 sales subsidiaries, modern warehousing, and quality instruments, EAGLE METALMARE's 1,200+ experts offer "EG" and "EGM" branded screws globally, along with one-stop procurement services for international tooling products.

10.Aozhan Industrial Co., Ltd.

Founded in October 2005, Aozhan Industrial Co., Ltd. is headquartered in Hangzhou, Zhejiang. This national high-tech enterprise specializes in research, production, sales, and services. Their primary focus lies in manufacturing high-quality precision fasteners and high-end stainless steel wire rods in various materials including stainless steel, special stainless steel, nickel-based alloys, chrome stainless steel, high-temperature alloys, titanium alloys, aluminum alloys, copper alloys, carbon steel, and chrome stainless materials.

Aozhan Industrial covers a vast industrial area of 300,000 square meters and operates several subsidiaries: Fu'an Aozhan Industrial Co., Ltd., Jiaxing Aozhan Industrial Co., Ltd., Zhejiang Aozhan Aviation Technology Co., Ltd., Zhejiang Ancheng Metal Products Co., Ltd., and Hangzhou Jinchang Intelligent Supply Chain Co., Ltd. They have established and deployed four automated warehouses in Jiaxing, Hangzhou, and Wenzhou, with additional warehousing and distribution centers in Shenzhen, Guangzhou, Qingdao, Tianjin, and other regions. Aozhan Industrial is dedicated to producing high-quality fastening components and premium stainless steel materials while continually expanding its operations to serve customers effectively.

Shanghai Prime Machinery Co., Ltd. (PMC), a state-owned enterprise under Shanghai Electric Group, is a leading name in the fasteners industry. Originating from Shang Biao Group and Shanghai Fasteners Import & Export Co., Ltd., it stands as China's largest professional fasteners manufacturer and exporter. PMC is recognized for its registered trademarks "SFC," "SV," and "Gu Ding."

PMC operates from its office on 15th Floor, 600 Heng Feng Road, Shanghai, with its manufacturing base in Yang Hang Industrial Zone, North Shanghai. This expansive facility covers 83,000 square meters, housing facilities for bolt forming, heat treatment, plating, packing, and inspections. With two automatic warehouses boasting 100,000 pallet spaces, advanced automation ensures quality and timely delivery.

PMC enjoys strong business ties with over 3,000 customers across 70 countries and regions. It holds certifications such as CE, ISO9001, ISO14001, and OHSAS18001, with its inspection center accredited by CNAS for third-party inspections. PMC consistently leads China's fasteners industry in export volume, offering a vast range of over 50,000 fastener sizes, including DIN, ASTM, and GB standards. Their product portfolio includes high-strength hex bolts, hex nuts, chipboard screws, and drywall screws, with various surface plating options. PMC welcomes both existing and prospective customers for discussions and visits.

Shenzhen Guwanji Hardware Technology Co., Ltd. is a professional enterprise specializing in the production and sale of industrial fasteners. With a strong competitive edge, extensive expertise, and a commitment to quality customer service, the company provides professional support and technical assistance to both new and loyal clients.

Established in 2014, Shenzhen Guwanji Hardware Technology Co., Ltd. prioritizes development and quality. It has earned the trust of a broad customer base through consistent product quality and a strong business reputation. The company stays attuned to market trends, continually developing new products to meet evolving customer needs. Quality management is central to its operations, with a dedication to delivering high-quality products as a primary objective. Managing product quality is a vital component of the company's strategic approach, ensuring unwavering product consistency.

Shanghai Qunli Fastener Manufacturing Co., Ltd. is a prominent large-scale enterprise specializing in the production of stainless steel and alloy steel fasteners. Their materials range from 304, 304L, 316, 316L, 2Cr13, to 660, F55, and more. With substantial capabilities, the company boasts a sprawling facility spanning 40,000 square meters within a 60-unit area. They employ over 100 dedicated professionals and maintain a robust technical foundation, equipped with advanced manufacturing and testing machinery.

With an impressive annual production capacity of 20,000 tons, Qunli offers a comprehensive range of products following standards such as GB, DIN, ANSI/ASME, ISO, and BS. These fasteners find applications across diverse industries, including mechanics, metallurgy, railways, bridges, aviation, architecture, chemistry, electronics, furniture, and automotive.

With over 30 years of experience, Qunli has honed its manufacturing expertise, utilizing top-quality materials, including 304, 316, and 316L super duplex stainless steel from Baosteel, all accompanied by raw material certificates. Their commitment to quality has earned them a strong presence in the Shanghai fastener market, where they are recognized as a trusted and well-established brand with a nationwide sales network.

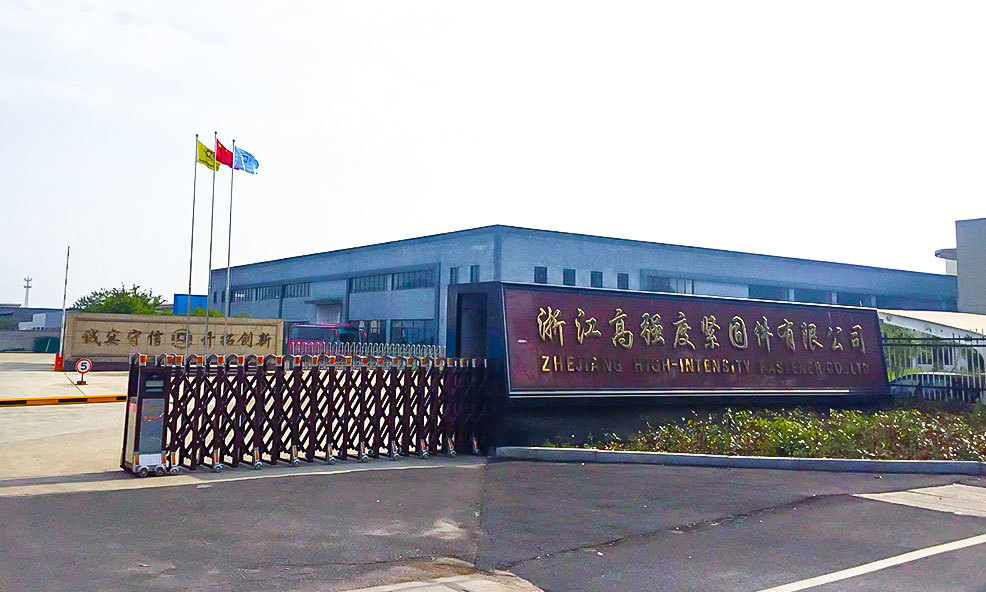

Zhejiang High-Strength Fasteners Co., Ltd. (a joint-stock enterprise) has nearly 30 years of history dedicated to designing, testing, and manufacturing high-strength fasteners, high-temperature preloaded disc springs, military-grade large flat spiral springs, and related products.

Their "Gaoqiang" brand fasteners and high-temperature preloaded disc springs find extensive applications in major national projects, including petroleum, chemical, shipbuilding, nuclear, large machinery, aerospace, and defense industries.

The company boasts robust technical expertise, well-equipped facilities, and attentive after-sales service. It holds certifications for ISO 9001:2015 quality management, GJB9001C-2017 military product quality management, national-level secrecy, ISO 14001:2015 environmental management, OHSAS 18001-2007 occupational health and safety management, and ISO 50001-2011 energy management systems.

Spanning an area of 90,712 square meters with over 60,000 square meters of workshop space, the company has a registered capital of ¥120 million and more than 400 sets of production and testing equipment. They produce a wide range of products conforming to GB, ANSI, DIN, EN, RCCM-2007, JIS, ISO, and industry standards (SH, HG, JB, GD, GJB) in sizes M12-M160, 1/2-6", including high-strength bolts, nuts, screws, and non-standard specialty fasteners. They also manufacture DIN2093, ANSI 693F, 20813, and GQDH632-A disc springs, and military-grade large flat spiral springs, accumulating 30 utility model patents to date.

Qifeng Precision Industry Sci-Tech Co., Ltd. is a high-tech enterprise specializing in the research, manufacturing, and testing of high-end fasteners. Their product range encompasses GB, JIS, ANSI, ISO standard fasteners, various non-standard fasteners, high-speed railway track bolts, and aerospace and defense fasteners. The company holds ISO9001-2008, GJB9001B-2009, and AS9100C-2009 quality system certifications and has been accredited by CNAS as a national laboratory, authorizing them to produce supporting products for aerospace, defense, and military research.

Qifeng prioritizes technological advancement, investing heavily in independent innovation and research. Their autonomous R&D capabilities have significantly grown over the years. Notably, their 2008 development of high-speed railway track bolts successfully replaced imports and has been adopted in multiple high-speed railway passenger lines like Jinghu, Jingguang, and Lanxin. In 2011, Qifeng entered the high-end fasteners sector for aerospace and defense, with their fastener series widely applied in national defense weaponry. They serve diverse industries, including aerospace.

Qifeng is committed to a path of military-civil integration and internationalization, emphasizing the coordinated development of military and civilian fasteners. They focus on the mid-to-high-end fastener business and pursue specialization, industrialization, and internationalization. With strategies for transformation, market expansion, innovation, and talent development, they aspire to become a leading domestic enterprise in the high-end standard fasteners and high-speed railway track bolt industry, excelling in research, production, and service.

In conclusion,

In the world of custom metal part hardware, China's fasteners manufacturers have earned their place as leaders through innovation, precision, and commitment to quality. The top 15 companies highlighted in this blog are not only capable of meeting domestic demands but also serve as global partners for industries requiring top-notch fastening solutions. As you explore the diverse offerings and capabilities of these manufacturers, you'll find a rich tapestry of expertise, from automotive fasteners to aerospace-grade components. When it comes to fasteners manufacturers in China, you can trust these industry leaders to provide the high-quality, custom metal parts hardware you need for your projects, setting the foundation for secure and reliable connections in various applications.