Screw Vs Nut Vs Bolt | What Are the Differences

In the realm of mechanical fasteners, screws, nuts, and bolts stand as distinct entities, each possessing its own unique characteristics and applications. These three components play a crucial role in various industries and engineering disciplines.

By exploring their differences, this article aims to provide a comprehensive understanding of the varied functions, strengths, durabilities, and utilities associated with screws, nuts, and bolts.

Delving into these distinctions will allow for a clearer comprehension of how these fasteners contribute to the mechanics of structures and machinery.

Key Takeaways

- Screws, nuts, and bolts have different designs and purposes. Wood screws are for wood, machine screws are for metal, self-tapping screws are for quick assembly, hex nuts are common, wing nuts are for easy hand tightening, locknuts prevent loosening, flange nuts distribute pressure, hex bolts are versatile, carriage bolts are for securing wood, and eye bolts are for lifting heavy loads.

- Screws create stability and prevent loosening, while nuts create tension and hold components tightly together. Thread engagement ensures a secure connection, and screws can be easily adjusted using tools.

- Bolts provide a strong connection with higher tensile strength and resistance to vibrations. Screws have superior shear force resistance and are suitable for frequent disassembly.

- Nuts and bolts are widely used in industries like automotive, construction, and manufacturing for reliable fastening, adjustability, load distribution, stability, and overall structural integrity.

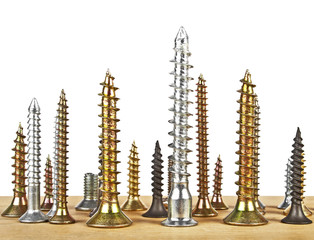

1. Types of Screws

Various types of screws, such as wood screws, machine screws, and self-tapping screws, differ in their design and intended applications.

Wood screws are specifically designed for use with wooden materials. They have a sharp point and coarse threads that provide excellent grip in wood. These screws often have a slotted head or a Phillips head for easy installation using a screwdriver.

Machine screws, on the other hand, are used in metal applications where a stronger fastening is required. They have finer threads and are typically tightened with the use of a nut or threaded into a tapped hole. Machine screws come in various head types including flathead, roundhead, and panhead.

Self-tapping screws are unique as they have the ability to create their own threads when driven into materials such as plastic or metal without the need for pre-drilling. This feature makes them ideal for applications where quick assembly is required.

In summary, different types of screws vary in their design and intended use based on the material they will be fastened to and the specific application requirements.

2. Different Types of Nuts

One type of fastener commonly used in mechanical applications is characterized by its shape and ability to secure other components. This type of fastener is known as a nut. Nuts play a crucial role in the assembly process, providing a means to securely attach various components together. There are several different types of nuts available, each designed for specific applications and requirements.

1. Hex nuts: These nuts have six flat sides and are the most common type of nut used in mechanical applications. They are easy to grip with a wrench and provide good stability when tightened.

2. Wing nuts: These nuts feature two large wings on opposite sides, allowing for easy hand tightening without the need for tools. They are often used in applications where frequent adjustments or removals are necessary.

3. Locknuts: As the name suggests, locknuts have mechanisms that prevent them from loosening under vibrations or other external forces. Some common types include nylon-insert locknuts and self-locking nuts.

4. Flange nuts: Flange nuts have an attached washer-like flange at one end, which helps distribute pressure and prevents damage to the surface being fastened.

With an understanding of different types of nuts, we can now move on to exploring the varieties of bolts commonly used in mechanical applications.

3. Varieties of Bolts

Different types of bolts are commonly used in mechanical applications, each designed with specific characteristics to meet different requirements and applications. Bolts are threaded fasteners that typically have a head on one end and a threaded shaft on the other. They are used to mechanically join two or more objects together by applying tension through the tightening of a nut.

To illustrate the variety of bolts available, the following table presents three common types along with their respective characteristics:

| Type | Characteristics | Applications |

| Hex bolt | Six-sided head, external threads over the entire length | General-purpose fastening |

| Carriage bolt | Circular head, square shoulder under the head, smooth shank with partial threading | Woodworking projects |

| Eye bolt | Loop at one end, threads at opposite end | Lifting heavy loads |

Each type of bolt has unique features that make them suitable for specific tasks. For example, hex bolts are versatile and widely used due to their strength and ease of installation. Carriage bolts are ideal for securing wood pieces as they prevent spinning during tightening. Eye bolts are specifically designed for lifting heavy loads.

Transitioning into the subsequent section about 'screw vs nut: function and purpose,' it is important to understand how bolts interact with nuts and screws as integral components in mechanical systems.

4. Screw Vs Nut: Function and Purpose

The function and purpose of screws and nuts can be elucidated by examining their respective roles in mechanical systems.

1. Screws:

Screws are cylindrical fasteners with helical ridges, called threads, running along their external surface. They are primarily used to hold objects together or to fasten them to a surface. The threads on the screw allow it to create its own path as it is driven into a material, providing stability and preventing loosening.

2. Nuts:

Nuts, on the other hand, are typically hexagonal-shaped objects with a threaded hole in the center. They are designed to be paired with screws or bolts and serve as a counterpart for fastening purposes. By turning the nut onto the screw or bolt, pressure is applied, creating tension that holds components tightly together.

3. Thread Engagement:

The interaction between screws and nuts involves thread engagement, where the threads of both components interlock securely. This ensures that the connection remains stable even under stress or vibrations.

4. Adjustability:

Unlike bolts which require a pre-drilled hole for installation, screws can be easily adjusted by simply turning them further into or out of an object using tools like screwdrivers or power drills.

From this understanding of screws and nuts, we can now delve into comparing their strength and durability in relation to bolts without explicitly stating a transition word or phrase between sections.

5. Bolt Vs Screw: Strength and Durability

Strength and durability play crucial roles in determining the performance of bolts and screws within mechanical systems. Bolts are designed to provide a strong and reliable connection between two or more components. They are characterized by their higher tensile strength, which allows them to withstand high levels of tension without breaking or deforming. This makes bolts ideal for applications where there is a need for secure fastening under heavy loads or in environments with significant vibrations.

On the other hand, screws are primarily used for securing objects together by creating threaded holes within one component and engaging with those threads using their helical ridges. While screws may not possess the same level of tensile strength as bolts, they make up for this with their superior resistance to shear forces. Additionally, screws offer excellent resistance against loosening due to rotational forces, making them particularly suitable for applications where frequent disassembly and reassembly is required.

The distinction between nuts and bolts lies in their usage and application rather than inherent differences in strength or durability. Nuts are typically used in conjunction with bolts to create a secure fastening system that can be easily tightened or loosened when necessary. In contrast, screws function independently but can also be combined with nuts if desired.

6. Nut Vs Bolt: Usage and Applications

The previous subtopic discussed the strength and durability differences between bolts and screws. Now, we will explore the usage and applications of nuts and bolts.

Nuts and bolts are commonly used in various industries for joining two or more parts together securely. Here are some key points regarding their usage:

- Fastening: Nuts and bolts provide a reliable method of fastening components together, allowing for easy disassembly if necessary.

- Adjustability:Unlike screws, which are threaded into materials directly, nuts can be tightened or loosened on the bolt to adjust tension or accommodate different thicknesses of materials.

- Load distribution:The use of nuts helps distribute the load evenly across the joint by providing a larger contact area compared to screws alone.

- Vibration resistance:Nuts and bolts offer greater resistance to vibration due to their secure fastening mechanism, making them suitable for applications where stability is crucial.

In automotive, construction, machinery, and countless other industries, nuts and bolts play a vital role in ensuring structural integrity and reliability. Their versatility makes them indispensable when assembling complex systems or securing heavy-duty structures together effectively.

Mikehardware-your trusted screw, nut and bolt supplier

In conclusion, this article has discussed the differences between screws, nuts, and bolts.

It has provided an overview of the various types of screws, nuts, and bolts available in the market.

The article has also explored their functions, purposes, strengths, and durability.

Furthermore, it has highlighted the specific usage and applications of nuts and bolts.

To sum up, understanding the distinctions between these fasteners is crucial for successful construction projects or any other application requiring their use.

Contact us Mikehardware to know more about screws, nuts, and bolts!