What Is Fastener Bolt?

Fastener bolts are essential components in various industries, playing a crucial role in joining two or more objects together. With a wide range of types and functions, fastener bolts offer versatility and reliability in numerous applications.

Understanding the importance of fastener bolts is imperative for engineers and professionals alike to ensure sturdy connections that withstand external forces. This article aims to provide an overview of fastener bolts, including their types, functions, common applications, factors to consider when choosing them, and tips for proper installation.

By delving into these topics, readers will gain valuable insights into the world of fastener bolts.

Key Takeaways

- Fastener bolts come in various types, including hex bolts, carriage bolts, machine screws, shoulder bolts, and anchor bolts.

- The functions of fastener bolts include joining objects securely, providing stability and structural integrity, distributing loads evenly, allowing for easy disassembly and reassembly, and ensuring the structural integrity of assembled components.

- Fastener bolts are important for load distribution, joint strength, and maintenance and repairs.

- Common applications of fastener bolts include construction projects, automotive assembly, and machinery manufacturing.

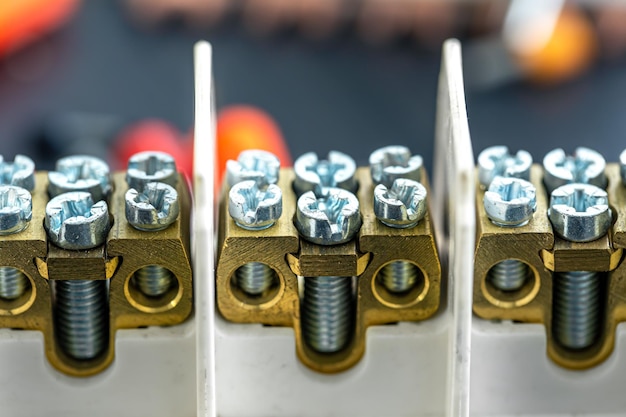

1. Types of Fastener Bolts

There are several types of fastener bolts that can be classified based on their structural design and intended application. One common type is the hex bolt, which has a hexagonal head and requires a wrench or socket for installation. Hex bolts are commonly used in construction and automotive industries due to their high strength and reliability.

Another type is the carriage bolt, characterized by its round, domed head and square shank beneath it. Carriage bolts are often used in wood-to-metal applications where a smooth finish is desired on the exposed side of the joint.

Machine screws are another category of fastener bolts that have a uniform diameter along their entire length and require a threaded nut for installation. They are commonly used in appliances, electronics, and machinery where precision is crucial.

In addition to these types, there are also shoulder bolts, which feature an unthreaded cylindrical section between the head and the threaded portion. These bolts allow for rotational movement or precise alignment of components.

Lastly, anchor bolts are designed specifically for securing structures to concrete foundations or walls.

Understanding the different types of fastener bolts is essential as it enables engineers and designers to select the most appropriate option for their specific applications. It ensures optimum performance and safety in various industries ranging from construction to manufacturing processes.

2. Functions of Fastener Bolts

One of the essential roles of fastener bolts is to securely join two or more objects together. Fastener bolts are mechanical devices that consist of a threaded shaft and a head, which may have various shapes such as hexagonal, square, or round. The threaded shaft allows the bolt to be inserted into holes in the objects being joined, while the head provides a surface for applying torque during installation and removal. Fastener bolts are commonly used in construction, automotive, aerospace, and many other industries.

In addition to their primary function of joining objects together, fastener bolts also serve several other important functions. They provide stability and structural integrity by holding components firmly in place. Furthermore, they help distribute loads evenly across multiple parts, preventing localized stress concentrations that could lead to failure. Fastener bolts also allow for easy disassembly and reassembly of components when maintenance or repairs are required.

The importance of fastener bolts cannot be overstated in various applications where secure connections are crucial for safety and functionality. Their ability to withstand forces such as tension, compression, shear, and bending ensures the structural integrity of assembled components. In the following section about 'importance of fastener bolts,' we will explore their significance in more detail.

3. Importance of Fastener Bolts

Fastener bolts play a critical role in ensuring the structural integrity and safety of assembled components. They are essential for various applications, ranging from construction to automotive industries. The importance of fastener bolts can be understood through the following key points:

- Load Distribution: Fastener bolts distribute the applied load evenly across multiple components, preventing stress concentration and potential failure.

- Joint Strength: Bolts provide high tensile strength, allowing them to withstand heavy loads and resist shear forces that may occur during operation or external impacts.

- Maintenance and Repairs: Bolts offer easy disassembly and reassembly during maintenance or repair procedures, reducing downtime and enhancing overall efficiency.

By understanding these factors, engineers and designers can make informed decisions regarding bolt selection, size, material, and torque specifications to ensure optimal performance. It is crucial to consider the specific requirements of each application to guarantee the reliability and functionality of fastened assemblies.

4. Common Applications of Fastener Bolts

Common applications of fastener bolts include construction projects, automotive assembly, and machinery manufacturing. Fastener bolts are widely used in these industries due to their ability to provide secure and reliable connections between various components.

In construction projects, fastener bolts are commonly used to join structural elements such as beams, columns, and trusses. The use of fastener bolts ensures the stability and integrity of the structures being built.

In automotive assembly, fastener bolts play a crucial role in joining different parts of vehicles together. They are used to connect engine components, body panels, chassis components, and other essential parts. The use of fastener bolts in automotive assembly ensures that the assembled vehicle is structurally sound and safe for operation.

Similarly, in machinery manufacturing, fastener bolts are utilized to assemble various machine parts together securely. These machines can range from small appliances to large industrial equipment. Fastener bolts provide the necessary strength and stability required for efficient machine operation.

When choosing fastener bolts for specific applications such as construction projects or machinery manufacturing, several factors need consideration. These factors include bolt size, material compatibility with the connected components or structures, load-bearing capacity requirements, environmental conditions (such as temperature fluctuations or exposure to corrosive substances), and ease of installation and maintenance. Taking into account these factors will help ensure the appropriate selection of fastener bolts for a given application without compromising safety or performance efficiency.

5. Factors to Consider When Choosing Fastener Bolts

When selecting fasteners for specific applications, it is important to consider factors such as bolt size, material compatibility, load-bearing capacity requirements, environmental conditions, and ease of installation and maintenance.

- Bolt Size:

- Ensure that the bolt size is appropriate for the application to prevent overloading or underperformance.

- Consider the diameter and length of the bolt to ensure proper fit and sufficient strength.

- Take into account any specific requirements or regulations regarding bolt sizes in the given industry or application.

- Material Compatibility:

- Choose a fastener bolt material that is compatible with the materials being joined.

- Consider factors such as corrosion resistance, temperature resistance, and electrical conductivity when selecting a suitable material.

- Load-bearing Capacity Requirements:

- Determine the maximum load that will be applied to the fastener bolts and select ones with an appropriate load-carrying capacity.

- Consider factors such as shear strength, tensile strength, and fatigue resistance when evaluating load-bearing capacity.

- Environmental Conditions:

- Assess the environmental conditions in which the fastener bolts will be used (e.g., temperature extremes, exposure to moisture or chemicals) to choose bolts with appropriate corrosion resistance or protective coatings.

Considering these factors ensures that fastener bolts are selected appropriately for their intended applications.

In order to properly install these selected bolts...

Mikehardware- your trusted fastener bolt supplier

In conclusion, fastener bolts serve a crucial role in various industries and applications. They come in different types to accommodate specific needs and functions. The importance of fastener bolts lies in their ability to provide secure and reliable connections, ensuring the safety and stability of structures or equipment.

When choosing fastener bolts, factors such as size, material, and strength should be considered. Proper installation is also essential for optimal performance.

With these considerations in mind, fastener bolts can effectively fulfill their purpose and contribute to the overall success of projects.

Contact us for a free quote of buy bulk fastener bolts!