Construction Screws Vs. Nails: Which Is Best for Your Project?

In the realm of construction, the choice between using screws or nails hinges significantly on the nature and demands of the project. While screws are celebrated for their robust clamping force and ease of removal, making them ideal for tasks requiring adjustments or disassembly, nails offer quicker installation and can be more cost-effective for large-scale constructions. Each fastener type brings distinct advantages and limitations to the table; hence, the decision must be meticulously aligned with project specifications, environmental conditions, and load requirements. As we explore these aspects further, one might wonder: in which scenarios might nails prove superior to screws, and vice versa?

Key Takeaways

- Construction screws offer superior pull-out resistance, ideal for dynamic forces in projects requiring high durability.

- Nails provide greater flexibility and are more cost-effective for large-scale structural applications.

- Screws are better suited for applications where precise placement and joint strength are critical, such as in cabinetry.

- Nails can be installed faster, making them more efficient for projects with tight timelines.

- Consider environmental factors and material compatibility; screws often feature coatings for enhanced weather resistance.

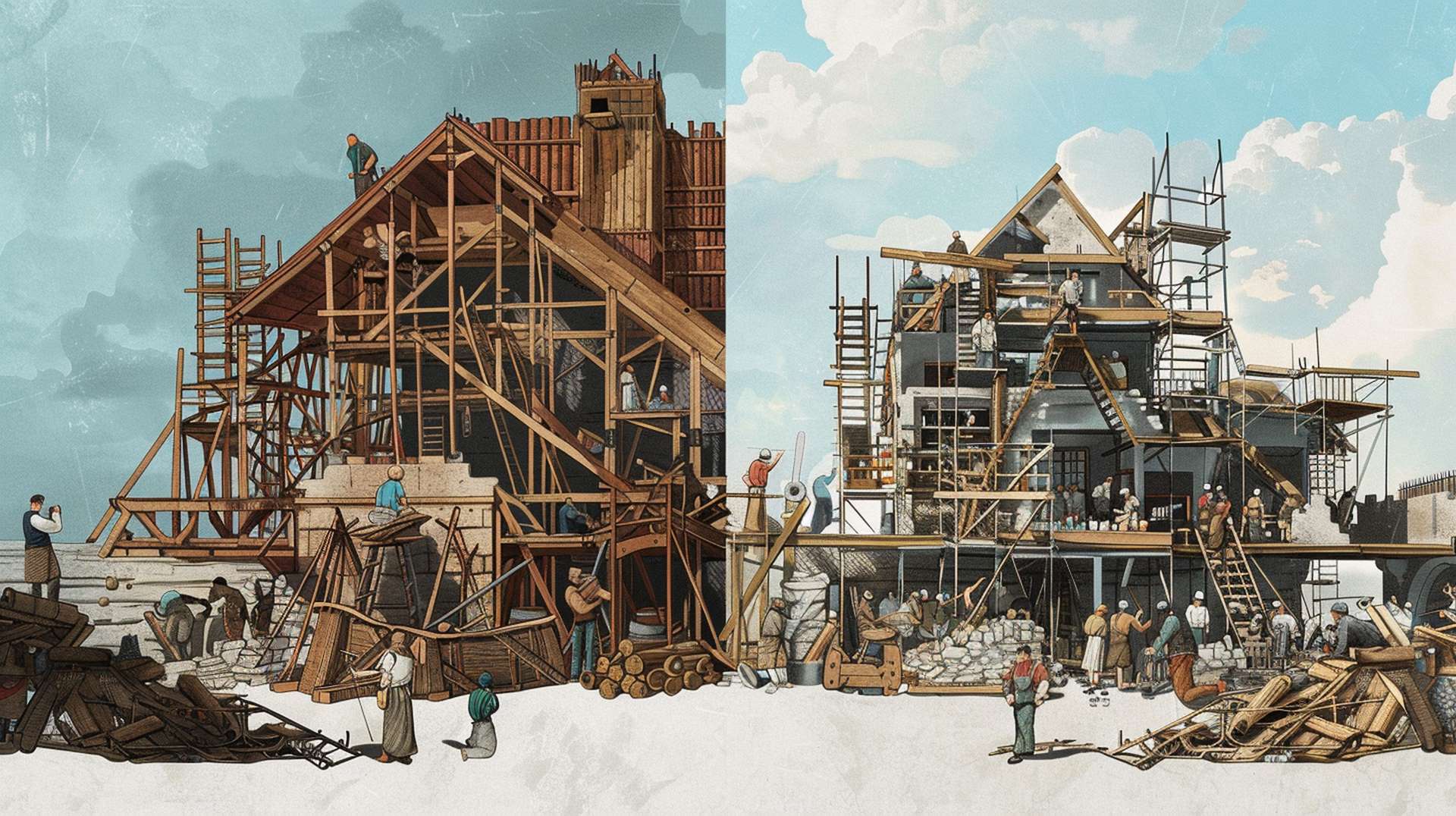

1. Nails Vs. Screws: A History

Exploring the historical evolution of nails and screws reveals a fascinating journey of innovation and practical application in construction. The evolution of fasteners, a pivotal component in building, highlights a timeline of technological advancements and shifting preferences.

Historically, nails were the go-to fasteners in construction due to their ease of use and speed of application. Hammering nails was considerably faster and required less skill than the laborious task of driving in slotted screws with tools like the manual or Yankee Screwdriver.

The introduction of the Phillips-head screw in the 1930s marked a significant turning point. This design offered a critical advantage—it was easier and quicker to drive than its predecessor, fundamentally altering the construction landscape. The impact of technology became even more pronounced with the development of electric and pneumatic screwdrivers, which facilitated the use of screws and reduced installation time dramatically.

However, the historical comparison between nails and screws is not just about technological evolution but also involves weighing their advantages and disadvantages. Nails are typically faster to install and less costly, while screws provide superior holding power and are easier to remove, making corrections feasible.

Traditional preferences often dictated the choice, but the ongoing advancements in fastener technology continue to influence these decisions.

2. How Nails and Screws Work?

How do nails and screws function as fasteners in construction projects?

Nails, typically with a flat head and smooth shank, are driven into materials using a hammer. This installation process is quick and enables effective load distribution across a simple interface.

Screws, on the other hand, feature a head with a drive and a threaded shank. They generally require a pre-drilled hole, particularly in tougher materials, where they cut their own threads—this action secures the screw, distributing the load along its threads for enhanced grip and stability.

The material properties of both nails and screws are crucial. Nails are often made from steel, providing strength but varying in corrosion resistance based on the type of coating or treatment. Screws, like deck screws used in wood construction, are specifically engineered to resist corrosion through coatings or galvanization, enhancing their longevity in diverse environmental conditions.

Furthermore, the environmental impact of each fastener type varies. The production and disposal of screws might have a higher environmental footprint due to their complex manufacturing process compared to the simpler, more energy-efficient production of nails. This aspect is essential when considering sustainable construction practices.

3. What's the Difference Between Screws and Nails?

While both nails and screws serve as essential fasteners in construction, they differ significantly in their application and physical characteristics. Nails have traditionally been the go-to choice for large-scale construction projects due to their cost-effectiveness and exceptional shear strength. This makes them ideal for situations where two surfaces slide past each other under pressure.

On the other hand, screws are favored for their superior tensile strength, making them better suited for projects where joined materials are under tension or bearing weight, such as in porch railings or cabinet installations.

- Material comparison: Screws are typically made from stronger materials than nails, which contributes to their higher tensile strength and enhanced durability.

- Installation process: Screws require a screwdriver or drill for installation, allowing for a more secure fit that is adjustable and reversible, unlike nails which are hammered in.

- Durability factor: Screws generally offer more longevity and can be more easily adjusted or replaced compared to nails.

- Load bearing capacity: Screws provide greater load bearing support, especially beneficial in structural applications where stability is crucial.

- Weather resistance: Screws often feature enhanced coatings that offer better resistance to corrosion and weather effects, making them ideal for outdoor applications.

4. When to Use Nails Vs Screws?

For example, screws are typically favored for decking and cabinetry due to their strong holding power and precision, while nails are often preferred in framing and exterior jobs for their rapid installation and cost-effectiveness.

Understanding the advantages of each in different contexts is crucial for achieving optimal results in construction projects.

Exterior Jobs

In exterior construction projects such as roofing, siding, and sheathing, nails are often favored due to their cost-effectiveness and suitability for securing large quantities of fasteners efficiently. This preference stems not only from the economic advantage but also from the practicality that nails bring to these specific applications.

When considering the diverse conditions these exterior elements face, choosing the right fastening solution becomes paramount.

- Siding Options: Pros and Cons: Nails provide quicker installation for various siding materials, though screws might offer better durability in high-wind areas.

- Roofing Materials: Durability Comparison: Nails are traditionally used for shingles due to their rapid application capabilities, but the choice between nails and screws can depend on the type of roofing material.

- Sheathing Techniques: Practicality Debate: Nails win in the speed and cost-efficiency debate, essential for sheathing large areas.

- Outdoor Construction: Weather Resistance: Nails are sufficient for most weather conditions; however, screws may be better for extreme environments.

- Fastening Solutions: Efficiency Comparison: While nails are faster and more cost-effective for large-scale jobs, screws provide superior holding power and adjustability in critical areas.

Selecting nails for typical exterior jobs offers a balanced approach between efficiency and performance, particularly where large-scale fastening is involved.

Decking Applications

Decking projects benefit significantly from using screws due to their enhanced holding power and ease of installation. The stronger hold that screws provide is crucial for the structural integrity and longevity of decking. This is particularly important in environments subject to weather variations that might cause wood to expand or contract. Screws are engineered to accommodate these changes without compromising the deck's stability.

Furthermore, recent advancements in fastener technology have streamlined the installation process for decking screws. Improved technology in decking tools and screws means they can be driven quicker and with greater precision, reducing labor time and costs. This is a key consideration when planning decking projects and upgrades, ensuring both efficiency and high-quality results.

Another significant advantage of using screws in decking applications is the option to use hidden fasteners. These systems allow screws to be installed in a way that makes them virtually invisible, enhancing the aesthetic appeal of the deck. This method not only improves the deck's appearance but also eliminates the risk of injury from exposed nail heads.

Framing Applications

When selecting fasteners for framing applications, it's essential to consider both nails and screws, each offering distinct advantages depending on the project requirements. Nails have traditionally been the go-to choice for framing due to their cost-effectiveness and rapid installation. However, advances in screw technology, including the development of pneumatic drivers, have positioned screws as a viable alternative, particularly where enhanced durability is required.

Here are key points to consider in the nails versus screws debate for framing:

- Strength comparison: Nails offer greater shear strength, ideal for withstanding lateral forces common in framing.

- Durability factors: Screws are less likely to loosen over time, providing a more durable, albeit initially more expensive, connection.

- Speed advantages: Nails can be driven faster, especially with pneumatic tools, speeding up the framing process significantly.

- Cost analysis: Nails are generally cheaper than screws, making them a cost-effective option for large-scale projects.

- Installation ease: While screws require more time for installation, advancements like pneumatic screw drivers are narrowing this gap, combining the ease of nail guns with the holding power of screws.

Interior Finishes& Flooring

Selecting the appropriate fasteners for interior finishes and flooring is crucial, with nails and screws each providing specific benefits suited to different types of installations. For interior trim, such as molding or baseboards, nails are often preferred due to their cost-effectiveness and ease of use. Their less prominent head makes them a discreet option for delicate trim pieces, ensuring a clean finish without visible fasteners.

When it comes to subflooring, screws are typically favored for their robust joint strength, which is essential in preventing the annoyance of squeaky floors. The secure fastening options offered by screws make them ideal for ensuring that subfloors are tightly affixed, minimizing movement and noise.

In the realm of hardwood floors, nails are commonly used because they allow the wood a bit of flexibility, which is necessary due to the natural expansion and contraction of the wood in response to environmental moisture. This flexibility helps in maintaining the integrity and appearance of hardwood floors over time.

For paneling, nails are again the fastener of choice. Their ability to provide a sufficient hold while allowing for natural wood movement is paramount in the attachment techniques of panel installations, ensuring both durability and aesthetic quality.

Cabinetry Applications

In cabinetry applications, screws are generally preferred over nails due to their superior joint strength and durability. This preference is critical in ensuring the long-term stability and integrity of cabinetry. Screws, by design, provide a more secure and adjustable means of assembly, which is essential in the precise and often intricate world of cabinet construction.

Here are key considerations when choosing between screws and nails for cabinetry:

- Cabinet Construction and Material Choice: Screws are better suited for handling the weight and wear experienced by cabinets, especially in materials like hardwood.

- Screw Types and Installation Process: Various screw types are available that are specifically designed for cabinet work, offering cleaner and more reliable installations.

- Nail Durability Vs. Cabinet Integrity: While nails may be quicker to install, they lack the grip strength provided by screws, risking the overall durability of the cabinet.

- Screw vs Nail Strength and Long-Term Stability: Screws ensure a stronger, more durable joint crucial for the long lifespan of cabinetry.

- Cabinet Design and Fastening Options: Screws offer greater versatility and can be adjusted or removed with minimal impact on the cabinet material, accommodating changes in design or repairs.

5. Can You Use Construction Screws for Framing?

In the context of construction, framing work serves as the backbone of any building project, necessitating a careful selection of materials.

The debate between using nails versus screws for framing hinges on factors such as structural integrity and ease of installation.

It is essential to choose the appropriate fasteners to ensure the durability and safety of the construction.

What Is Framing Work?

Framing work involves constructing the essential support structure of a building by securing wooden components together with either nails or screws. This process is fundamental in setting up the building framework, which supports various loads and stresses a structure might face over its lifespan.

Framing is not just about piecing wood together; it encompasses a broad range of construction essentials that ensure the safety and durability of the building. Understanding the framing basics is crucial for anyone involved in construction or home improvement. The choice between using nails or screws affects the integrity and longevity of the structural elements.

To better understand framing, consider these key points:

- Framing Basics: It's the process of creating the skeleton of a building.

- Structural Elements: Includes studs, joists, and beams that are critical for structural integrity.

- Building Framework: The layout that defines the shape and size of the building.

- Wood Attachments: The methods used to connect different pieces of wood within the framework.

- Construction Essentials: Techniques and materials fundamental to building construction.

Each component plays a vital role in ensuring that the framed structure meets all required standards and functions as intended.

Is Framing Better with Nails or Screws?

Deciding whether to use nails or screws for framing hinges on several factors, including the specific needs of the project and the materials involved. When examining the strength comparison, nails generally offer greater sheer strength, which is crucial in large-scale framing projects. They are designed to withstand the forces and weight that framing structures typically endure.

The installation process of nails is also faster and more efficient due to their compatibility with hammers and pneumatic nail guns, tools commonly used in construction framing. Durability factors favor nails as well, as their ability to flex under pressure minimizes the risk of damage under shifting loads or seasonal changes in wood.

This flexibility ensures long-term performance without loosening, which is vital in maintaining the structural integrity of framed buildings. Material compatibility also leans towards nails, especially when working with traditional wood framing, as they are less likely to cause splitting.

Get the Right Materials for Your Project

Understanding the requirement for the right materials, one may question if construction screws can be effectively used for framing. At Fastener USA, we recognize that each construction element demands specific types of fasteners to ensure both durability and structural integrity. Though traditionally, nails have been the go-to for framing due to their shear strength, modern advancements have made screws a viable option for certain framing applications, depending on the project requirements.

Construction screws offer several advantages that could influence their suitability for framing:

- Material Suitability: Screws are made from various metals that can be chosen based on environmental conditions and material compatibility.

- Project Requirements: Specific screw types are designed for different loads and types of wood or metal, allowing for a more tailored approach.

- Durability Comparison: Screws generally provide a stronger hold due to deeper thread engagement and resistance to pull-out.

- Application Versatility: They can be used in both temporary and permanent installations and are easier to adjust or remove if necessary.

- Installation Ease: With the correct tools, screws can be driven quickly and precisely, reducing labor time and potential errors.

Choosing the right type of screw for framing depends heavily on these factors, ensuring the construction is safe and up to code.

6. Nails Vs Screws: Factors to Consider

When choosing between nails and screws for construction projects, several key factors must be considered. These include the specific type of project and available tools, the required flexibility versus holding power, and whether the fasteners can be interchangeably used in certain contexts.

Each of these elements plays a crucial role in determining the most effective and efficient choice for securing materials in various construction scenarios.

1. Type of Project and Tools

Selecting between nails and screws for construction projects depends significantly on the scale and nature of the task, as well as the tools available for execution. For large-scale constructions such as house framing, nails are typically favored due to their strength and cost effectiveness. They can be easily driven into materials using basic hammers or more sophisticated nail guns, catering well to rapid, heavy-duty tasks.

On the other hand, screws are preferable for projects that require precision and the ability to disassemble, such as in DIY projects and home repairs. The use of power tools like electric drills enhances the efficiency and ease of driving screws, making them ideal for detailed woodworking applications and the manipulation of diverse construction materials.

To help decide which fastener is right for your project, consider the following:

- Power tools: Availability and type (e.g., nail gun or electric drill)

- DIY projects: Scale and need for reversibility

- Woodworking applications: Detail and precision required

- Home repairs: Frequency of disassembly and reassembly

- Construction materials: Suitability for nails or screws based on material properties and project durability requirements

2. Flexibility Vs. Holding Power

In construction, the choice between using nails or screws often hinges on balancing flexibility with holding power. Nails provide a robust solution where durability and stability are paramount—ideal for structural components like framing and hardwood floors. Their ability to be driven quickly lends convenience, especially in high-volume tasks. However, their fixed nature means lesser versatility compared to screws.

Screws, on the other hand, excel in longevity and adaptability. Their threaded design offers superior holding power, crucial for ensuring the reliability of joinery in furniture and hardware installations. This design also allows for the disassembly and reassembly of components, enhancing convenience and adaptability in projects that may require future modifications. Furthermore, screws are better suited for delicate materials, where their precise insertion minimizes damage and maintains material integrity.

Thus, the decision between nails and screws should consider the trade-offs between strength and convenience. While nails offer speed and reliability in permanent installations, screws provide ease of use and flexibility for adjustments.

Each fastener serves distinct purposes, influenced by the project requirements and the desired longevity of the construction.

3. Interchangeability in Certain Situations

Several factors must be considered when deciding whether nails or screws are more appropriate for specific construction tasks, as each fastener type offers unique advantages in certain situations. When choosing between screws and nails, the following points can help guide the decision process:

- Material Compatibility: Screws are often better suited for metal fixtures or hardwood, where their threads provide superior grip, while nails are ideal for softer woods and applications where slight flexibility is needed.

- Environmental Impact: Nails generally have a lower carbon footprint and are less energy-intensive to produce than screws. However, if the application demands frequent replacement or maintenance, screws might be a more sustainable choice over the long term.

- Maintenance Requirements: Screws offer easier maintenance as they can be easily removed and replaced without causing significant damage to materials, whereas nails, once driven, are more destructive to remove.

- Long Term Durability: Screws are less likely to loosen over time, making them ideal for areas subject to vibration or dynamic loads. Nails, however, can provide durable joints in static environments.

- Ease of Installation: Nails can be faster and easier to install using a nail gun, which can significantly speed up large projects, while screws require more time for proper alignment and driving.

7. Are Construction Screws Equivalent to a Framing Nails?

Determining whether construction screws can serve as effective substitutes for framing nails depends significantly on the specific requirements of the building project and local environmental conditions. In terms of fastener comparison, both screws and nails offer distinct advantages, but their application should be guided by their mechanical properties and the demands of the project.

Construction screws generally provide superior pull-out resistance compared to nails, making them an excellent choice for projects where the structural components are subjected to dynamic forces that may cause nails to loosen over time. This attribute particularly benefits installations where long-term stability is crucial.

However, in environments prone to seismic activity, the flexibility of nails may be advantageous as they can slightly move within their fittings without compromising the overall structural integrity.

Moreover, the shear strength of screws is often highlighted as comparable to that of nails, which supports their use in various framing applications. Manufacturers like GRK provide specific ratings for these properties, allowing builders to make informed decisions based on empirical data.

Material compatibility also plays a crucial role; screws are available in a variety of compositions suitable for different materials, enhancing project suitability across diverse construction scenarios.

8. Why Nails Are the Preferred Fastener in Construction

Nails have long been the go-to fastener in construction due to several key advantages. Their cost-effectiveness makes them an appealing choice for large-scale projects where budget constraints are significant.

Additionally, the inherent strength and flexibility of nails provide essential support and resilience in building structures.

Cost-Effectiveness

In terms of cost-effectiveness, nails are generally preferred over screws in construction due to their lower price point. The financial benefits of using nails are significant, particularly in large-scale projects where the volume of fasteners can heavily impact the overall budget.

This economical choice not only supports cost savings but also enhances the budget-friendly nature of construction projects.

- Lower Unit Cost: Nails are cheaper per unit compared to screws, offering substantial cost savings, especially in projects requiring a large number of fasteners.

- Bulk Availability: Nails can be purchased in bulk more economically, which is ideal for extensive construction projects.

- Reduced Labor Costs: Nails require less labor for installation since they can be used with high-speed nail guns, unlike screws which often require pre-drilling and more time for manual insertion.

- Minimized Waste: With fewer breakages and a simpler installation process, nails produce less waste during construction, further saving costs.

- Streamlined Procurement: The availability and demand for nails make them a more straightforward procurement choice for contractors, ensuring projects stay within financial forecasts.

Choosing nails for construction projects clearly supports cost effectiveness, making them a preferred choice for those looking to optimize financial resources in building endeavors.

Strength and Flexibility in Large Structures

Frequently, the choice of nails over screws in large structures is justified by their superior tensile strength and ease of installation. Nails, lacking threads, possess inherent robustness that enhances their load bearing capacity, crucial for maintaining structural integrity in substantial constructions. The material composition of nails allows them to absorb impacts and dynamic loads better than the more brittle screws, which are susceptible to breaking under similar conditions.

| Feature | Nails | Screws |

|---|---|---|

| Installation Speed | Fast (no pilot hole needed) | Slower (pilot hole required) |

| Tensile Strength | High (flexible under stress) | Lower (brittle under stress) |

| Removal Ease | Easy (hammer only) | Difficult (screwdriver needed) |

In terms of strength comparison, nails clearly outperform screws in scenarios demanding flexibility and durability. Durability testing shows that nails typically withstand the wear and tear of environmental stresses better than screws, making them more suitable for long-term construction projects. Ultimately, when evaluating which fastener to use in large structures, considering the balance between installation efficiency, resilience, and long-term performance is crucial. Nails often emerge as the superior choice due to their combined physical properties and practical benefits in construction settings.

Frequently Asked Questions

How Do Environmental Conditions Affect Screw and Nail Performance?

Environmental conditions significantly impact fastener performance. Temperature impacts, humidity effects, and moisture resistance are crucial in preventing corrosion. Additionally, wind load considerations are essential for ensuring long-term durability and structural integrity.

What Are the Latest Innovations in Screw and Nail Technology?

Recent advancements in screw and nail technology include self-drilling screws with enhanced corrosion resistance, non-threaded nails with increased impact strength, and options made from composite materials, improving durability and application efficiency across various environments.

Can Screws Be Used for Temporary Construction?

Screws can indeed be utilized for temporary fastening in construction projects. They provide flexibility and are easily removable, making them suitable as temporary solutions where alterations or adjustments might be required.

How Do You Remove Damaged Screws Without Harming Wood?

To remove damaged screws without harming wood, utilize specialized screw extraction tools and techniques that ensure efficient removal while preserving the wood. Employing gentle methods minimizes damage and facilitates effective repair and restoration.

Are There Specific Nails or Screws for Different Types of Wood?

Yes, specific nails and screws are recommended based on wood type, including distinctions between hardwood (oak) vs. softwood (pine), exterior vs. interior applications, and pressure-treated vs. regular wood, as well as plywood vs. particleboard.

Mikehardware-your trusted custom screws manufacturer

In conclusion, both nails and screws present distinct advantages depending on the demands of the construction project. Nails offer enhanced flexibility and adaptability in seismic conditions, while screws provide superior holding power and durability against dynamic forces.

Careful consideration of the project's specific requirements will guide the choice between these fasteners, ensuring structural integrity and longevity. Ultimately, the decision hinges on aligning the fastener's characteristics with the project's unique environmental and mechanical stresses.

At Dongguan Mike Hardware Co., Ltd., precision engineering meets innovation, delivering impeccable CNC product manufacturing solutions. Explore our array of customized fasteners, screws, and coatings, ensuring your projects excel in performance, precision, and quality.

Elevate your engineering prowess with our tailored solutions—Contact us for a free quote of your ideal custom screws.