A Guide to Choosing the Right Screw Heads Type

When it comes to fastening materials securely, selecting the appropriate screw head type is key.

The vast array of screw heads available can often be overwhelming, leaving many unsure of which one to choose for their project.

Understanding the different types of screw heads, their applications, and the materials they work best with can make a significant difference in the outcome of your project.

Let's explore the nuances of various screw head types and how to make informed decisions when faced with this essential choice.

Key Takeaways

- Consider compatibility factors when choosing a screw head type.

- Evaluate the material requirements to determine the optimal screw head type for the job.

- Assess specific application requirements to select the most suitable screw head shape.

- Take installation techniques and appearance into account when deciding on a screw head type.

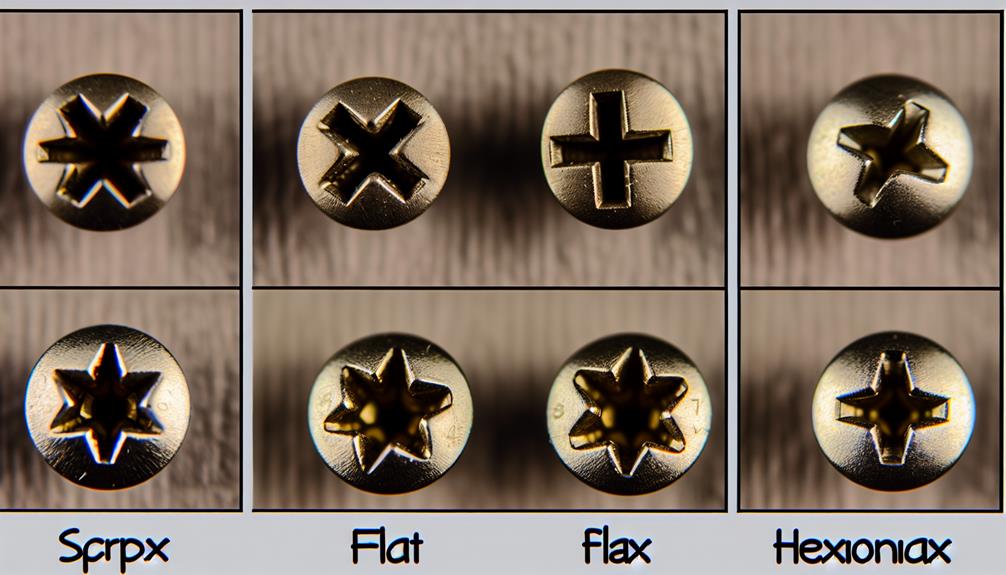

Types of Screw Heads

Exploring the diverse array of screw head types is essential for understanding the practical applications and nuances of fastening systems. When it comes to screw head durability and aesthetics, different types offer varying levels of resilience and visual appeal. For instance, flat heads provide a flush finish, ideal for applications where a sleek look is desired, while pan heads offer increased durability and are suitable for heavy-duty fastening.

Considering screw head compatibility and usability is crucial when selecting the right type for a specific project. Phillips heads are widely compatible and easy to use with power tools, making them a popular choice for general applications. On the other hand, Torx heads provide better resistance to cam out, reducing the likelihood of damaging the screw head or the tool during installation.

Common Screw Head Shapes

Understanding the practical applications of screw head types leads us to explore the common screw head shapes utilized in various fastening systems. Different screw head shapes offer unique advantages based on their design and function.

Here are some common screw head shapes to consider:

- Flat Head: Known for its countersunk design, ideal for applications requiring a flush surface finish. Offers high screw head compatibility with various tools and materials.

- Round Head: Provides a large contact area, distributing torque evenly for secure fastening. Suitable for applications where high torque requirements are necessary.

- Pan Head: Features a slightly rounded top with short vertical sides, enhancing screw head aesthetics while offering easy installation and removal. Ideal for applications where installation ease is a priority.

- Hex Head: Known for its hexagonal shape, enabling better control during installation with a wrench or socket. Provides high torque capabilities, making it suitable for heavy-duty fastening tasks.

Factors to Consider

When selecting the appropriate screw head type for a specific application, it is crucial to consider various factors that can impact the overall performance and effectiveness of the fastening system. Compatibility factors play a significant role in ensuring that the screw head type is suitable for the material being fastened and the specific requirements of the project. Different materials may require different screw head types to achieve optimal results. Additionally, understanding the installation techniques required for each screw head type is essential to ensure a secure and durable connection.

Size options are another critical factor to consider when choosing the right screw head type. The size of the screw head should match the size of the screw and the intended application to provide adequate support and strength. Moreover, appearance considerations should not be overlooked, especially in projects where aesthetics are important. The choice of screw head type can affect the overall look of the finished product, so selecting a type that complements the design is essential for a polished outcome.

Best Screw Head Type for Materials

Considering the specific material being fastened is paramount when determining the most suitable screw head type for optimal performance. Different materials require different screw head types to ensure a secure and lasting connection. Selecting the optimal choice will not only improve the overall strength of the fastening but also prevent damage to the material being worked on.

Here are some key considerations for choosing the best screw head type for various materials:

- Wood: For wood, flat or countersunk screw heads are commonly used as they can sit flush with the surface, providing a neat finish.

- Metal: Pan head screws are ideal for metal applications due to their rounded top that offers good surface contact and prevents over-tightening.

- Plastic: Truss head screws work well with plastic materials, offering a larger surface area to distribute the force and reduce the risk of cracking.

- Drywall: Bugle head screws are preferred for drywall installations as they have a tapered design that helps prevent tearing and provides a smooth surface appearance.

Tips for Choosing the Right Screw Head

To make an informed selection of the appropriate screw head type, it is essential to assess the specific requirements of the application and the materials involved. When choosing the right screw head, consider factors such as installation techniques, screw head visibility, compatibility with the material, and aesthetic appeal.

Different installation techniques, such as using a Phillips head or a Torx head, can impact the ease and security of fastening the screw. Screw head visibility is crucial for applications where the screw head needs to be flush with the surface or hidden from view. Additionally, ensuring the compatibility of the screw head with the material being used is vital to prevent stripping or damage during installation.

Lastly, the aesthetic appeal of the screw head should also be taken into account, especially for projects where design matters. By carefully evaluating these factors, you can choose the right screw head type that meets your specific needs and requirements.

Frequently Asked Questions

Can Different Screw Head Types Be Used Interchangeably for the Same Project?

Interchangeable screw heads can vary in compatibility for a specific project. It is crucial to consider factors such as material, torque requirements, and aesthetics when selecting the right screw head type to ensure optimal performance and functionality.

Are There Any Special Tools Required for Installing Specific Screw Head Types?

Tool compatibility is crucial for specific screw head types, enhancing installation efficiency. Some may require unique tools for optimal results. Understanding maintenance requirements ensures long-term durability. Adhering to these guidelines empowers users to achieve project precision.

How Do Screw Head Types Affect the Overall Aesthetics of a Project?

The aesthetics impact of a project can be significantly influenced by screw selection. Various design options exist for screw heads, allowing for customization and alignment with the overall visual appeal. Careful consideration of screw head types is essential.

Are Certain Screw Head Types More Prone to Stripping or Damage During Installation?

Selecting the right screw head material is crucial in preventing stripping or damage during installation. Proper techniques, like applying consistent pressure and using the correct size and driver, are essential for a successful outcome.

Can Screw Head Types Affect the Overall Durability and Longevity of a Project?

Different screw head types can influence a project's durability. Proper material compatibility, installation techniques, corrosion resistance, and load-bearing capacity are crucial factors. Choosing the right screw head type can significantly impact the longevity of a project.

Conclusion

In conclusion, the choice of screw head type can greatly impact the success of a project. By considering factors such as material compatibility and application requirements, one can ensure a secure and efficient fastening solution.

Remember, just as different screw heads serve different purposes, each decision we make in life can symbolize the building blocks of our journey towards success. Choose wisely, and watch your projects come together seamlessly.