The Role of Special Screw Manufacturers in Custom Hardware

Specialized screw manufacturers play a crucial r ole in the realm of custom hardware by offering tailored solutions to industries with specific requirements. These manufacturers are equipped with the expertise to craft screws that meet unique specifications, ensuring precision and reliability in various applications. From aerospace to automotive sectors, the demand for specialized screws continues to grow, highlighting the importance of these manufacturers in delivering high-quality components.

Their ability to collaborate with clients for custom designs sets them apart, making them indispensable partners in the creation of distinctive hardware. As we explore the intricate world of custom hardware and the role of special screw manufacturers within it, we discover a realm where precision and innovation intersect to shape the future of engineering solutions.

Key Takeaways

- Specialized screw manufacturers play a crucial role in ensuring precision, reliability, and efficiency in custom hardware production.

- These manufacturers offer custom solutions tailored to meet the specific needs of industries like aerospace, automotive, and electronics, focusing on enhancing performance, durability, and reliability.

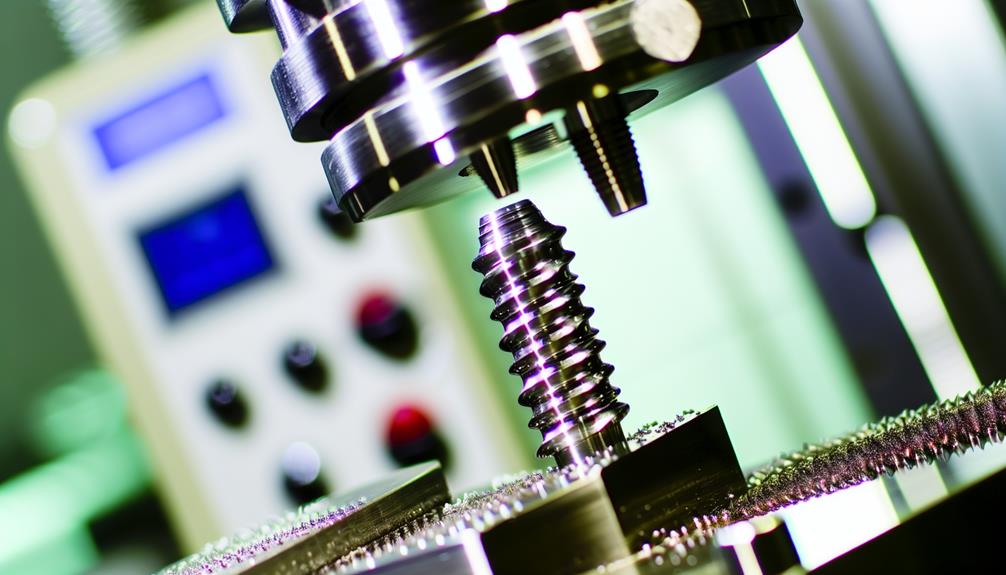

- Precision engineering and tailored designs are integral for creating screws that meet the exacting requirements of specialized industries, utilizing advanced technologies like CAD/CAM software and CNC machining.

- Collaborative partnerships with specialized screw manufacturers can lead to the development of unique components that align with industry standards and address complex challenges effectively.

Importance of Specialized Screw Manufacturers

Specialized screw manufacturers play a crucial role in ensuring precision, reliability, and efficiency in custom hardware production. Their specialized expertise allows for the creation of screws tailored to meet specific needs and industry standards. Specialized screw manufacturers understand the intricate requirements of various sectors, such as aerospace, automotive, and electronics, ensuring that the screws produced meet the stringent quality and performance criteria set by these industries.

By specializing in screw production, manufacturers can focus their efforts on perfecting the design, material selection, and manufacturing processes required to produce high-quality screws. This dedication to specialization results in superior products that offer enhanced durability and performance compared to standard screws.

Moreover, specialized screw manufacturers adhere strictly to industry standards to guarantee that the screws meet the necessary specifications for compatibility and reliability. This commitment to quality and precision is essential in custom hardware production, where even the slightest deviation from standards can lead to product failure or performance issues.

Custom Solutions for Diverse Industries

Given the intricate requirements of various sectors like aerospace, automotive, and electronics, specialized screw manufacturers offer custom solutions tailored to meet the specific needs of diverse industries. These custom solutions often involve precise custom fabrication processes to ensure the screws meet the exact specifications demanded by different industry applications. By understanding the unique challenges faced by sectors such as aerospace, automotive, and electronics, special screw manufacturers can develop custom solutions that enhance the performance, durability, and reliability of the end products.

| Industry | Custom Solution Offered |

|---|---|

| Aerospace | Specialized aerospace screws designed for high-stress environments and extreme temperature variations. |

| Automotive | Customized automotive fasteners that prioritize corrosion resistance and structural integrity to enhance vehicle safety. |

| Electronics | Precision electronic screws manufactured with tight tolerances to ensure compatibility and longevity in electronic devices. |

Through their expertise in custom fabrication techniques and deep understanding of industry-specific requirements, specialized screw manufacturers play a crucial role in providing tailored solutions that meet the stringent demands of diverse industries.

Precision Engineering and Tailored Designs

Precision engineering techniques are integral to the creation of tailored designs that meet the exacting requirements of specialized industries. When it comes to providing tailored solutions for custom hardware needs, precision manufacturing plays a crucial role in ensuring the highest quality and functionality of the final products. Special screw manufacturers employ advanced engineering processes to deliver customized solutions that align perfectly with the unique specifications of each client.

Here are some key aspects to consider in precision engineering and tailored designs:

- Advanced CAD/CAM Software: Utilized for precise design and modeling of custom screw components.

- CNC Machining Technologies: Ensuring accuracy and consistency in the manufacturing process.

- Material Selection Expertise: Choosing the right materials based on performance requirements.

- Quality Control Measures: Implementing rigorous testing procedures to guarantee product reliability.

- Customization Flexibility: Adapting designs to meet specific industry demands and standards.

Role in High-Quality Custom Hardware

Manufacturers of custom hardware play a crucial role in ensuring the production of high-quality components that meet the specific needs and standards of diverse industries. These manufacturers specialize in creating bespoke solutions that require high precision and attention to detail. When it comes to high-quality custom hardware, precision is paramount. Special screw manufacturers excel in producing components with exact specifications, ensuring they fit seamlessly into the final product.

In the realm of custom hardware, the demand for high precision is non-negotiable. Manufacturers that provide custom solutions must adhere to strict quality control measures to guarantee that each component meets the required standards. The role of special screw manufacturers in delivering high-quality custom hardware cannot be overstated. Their expertise in creating precision-engineered components is essential for industries where off-the-shelf solutions fall short. By offering custom solutions tailored to the precise needs of their clients, these manufacturers contribute significantly to the production of top-tier custom hardware.

Collaborative Partnerships for Unique Components

Collaborating with specialized custom hardware providers enhances the creation of unique components tailored to the specific requirements of diverse industries. By engaging in collaborative partnerships for unique components, industries can benefit from a tailored approach that meets their specific needs. This collaboration fosters innovative solutions and ensures the development of high-quality unique fasteners that align with industry standards.

Benefits of Collaborative Partnerships for Unique Components:

- Enhanced Customization: Working closely with custom hardware providers allows for tailored solutions to meet unique specifications.

- Access to Specialized Expertise: Leveraging the knowledge and experience of specialized providers ensures the development of optimal unique fasteners.

- Cost-Effective Solutions: Collaborative innovation often leads to cost efficiencies through streamlined processes and optimized designs.

- Quality Assurance: Partnering with experts in custom hardware guarantees the production of high-quality unique components.

- Innovative Problem-Solving: Joint collaboration encourages creative problem-solving, leading to innovative solutions for complex challenges.

Frequently Asked Questions

Are There Any Limitations to the Types of Materials That Specialized Screw Manufacturers Can Work With?

Specialized screw manufacturers may face limitations in materials compatibility, impacting innovation and design flexibility. Understanding these constraints is crucial for ensuring custom hardware meets specific requirements while maintaining quality and functionality.

How Do Specialized Screw Manufacturers Ensure the Security and Confidentiality of Custom Designs for Diverse Industries?

Special screw manufacturers uphold data protection for diverse industries by implementing stringent security measures to safeguard custom designs. They prioritize intellectual property by employing confidential protocols, ensuring the security and confidentiality of valuable information.

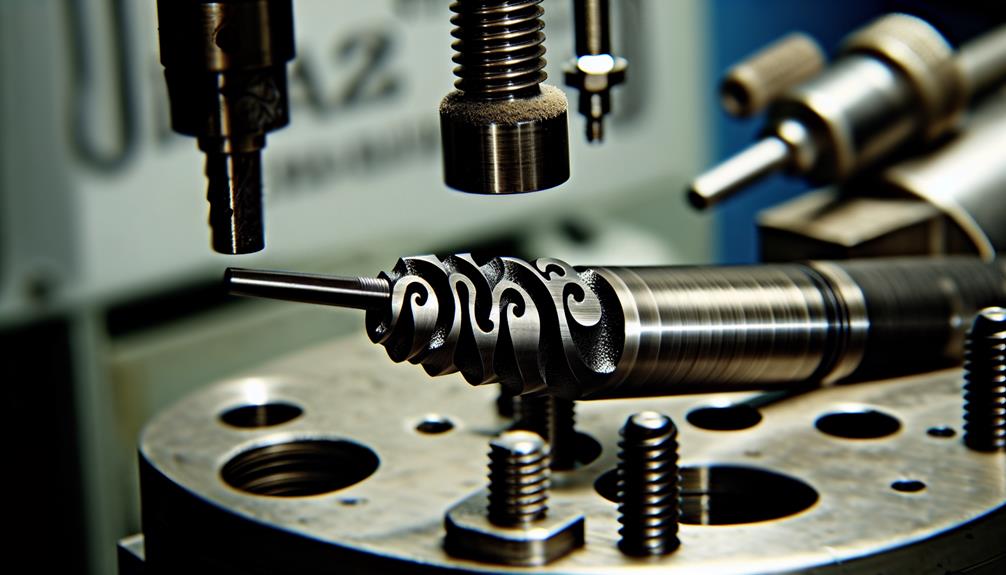

What Are Some Examples of Complex Geometries or Unique Features That Can Be Achieved Through Precision Engineering in Screw Manufacturing?

Precision engineering in screw manufacturing allows for intricate geometries like specialized thread patterns, unique head shapes, or custom lengths. Innovative solutions can include self-locking mechanisms, tamper-resistant designs, or materials tailored for specific environments, enhancing security and performance.

Can Specialized Screw Manufacturers Accommodate Rush Orders or Tight Deadlines for High-Quality Custom Hardware?

In a world of demanding timelines, specialized screw manufacturers excel in accommodating rush orders and tight deadlines without compromising on quality. They navigate material limitations with precision while upholding stringent confidentiality measures for custom hardware projects.

How Do Collaborative Partnerships Between Specialized Screw Manufacturers and Clients Typically Begin, and What Is the Process for Bringing Unique Components to Market?

Client collaboration is vital for successful market launch strategies. Typically, partnerships with specialized screw manufacturers start with detailed discussions on component requirements, followed by prototyping and testing phases. This process ensures unique components meet client expectations.

Mikehardware-your trusted Custom Screw manufacturer

In conclusion, specialized screw manufacturers play a crucial role in providing custom solutions for diverse industries. Through precision engineering and tailored designs, they contribute to the production of high-quality custom hardware.

Collaborative partnerships with these manufacturers can lead to the creation of unique components that meet specific requirements. Their expertise and capabilities make them essential in the development of customized hardware solutions for various applications.

At Dongguan Mike Hardware Co., Ltd., precision engineering meets innovation, delivering impeccable CNC product manufacturing solutions. Explore our array of customized fasteners, screws, and coatings, ensuring your projects excel in performance, precision, and quality.