How to Measure Length of Bolt?

This article aims to provide a comprehensive guide on the measurement of bolt length. Bolts, being integral components in various industries, necessitate accurate measurements for their effective utilization.

By exploring different types of bolts and common measurement techniques, this article will equip readers with the necessary knowledge and tools required for accurate bolt length measurement. Additionally, it will highlight common mistakes to avoid during the process.

The objective and impersonal style of writing employed throughout ensures an unbiased presentation of information for academic purposes.

Key Takeaways

- Bolt length is measured from the underside of the head to the tip using tools such as rulers, tape measures, or specialized gauges.

- To ensure accuracy, it is important to remove any dirt or debris from the threads before measuring the bolt length.

- Alternatively, you can measure the bolt length by screwing a nut onto the threads until it reaches flush with the end of the bolt and measuring from the underside of the head to just below where the nut is located.

- Accurate bolt measurements are crucial for safety, efficiency, cost-effectiveness, reliability, and industry relevance in various sectors such as construction, automotive, and manufacturing.

1. Different Types of Bolts

There are various types of bolts available, each with distinct characteristics and applications. Bolts are mechanical fasteners used to join two or more objects together. They provide a secure and reliable connection, ensuring the stability and integrity of structures.

One common type of bolt is the hex bolt, which has a hexagonal head and threads on the shank. It is widely used in construction, machinery, and automotive industries due to its versatility and strength.

Another type is the carriage bolt, which has a rounded head and a square section under it to prevent rotation during installation. Carriage bolts are commonly used in woodwork applications where aesthetics are important.

In addition to these, there are also eye bolts that have a looped head for attaching cables or hooks; U-bolts that form a U-shape for securing pipes or tubes; and anchor bolts that are embedded in concrete foundations to provide stability.

Understanding the different types of bolts is crucial as it allows individuals to select the appropriate kind for their specific application. This knowledge will further aid in accurately measuring the length of bolts required for any given project, as explored in the subsequent section on common bolt measurements.

2. Common Bolt Measurements

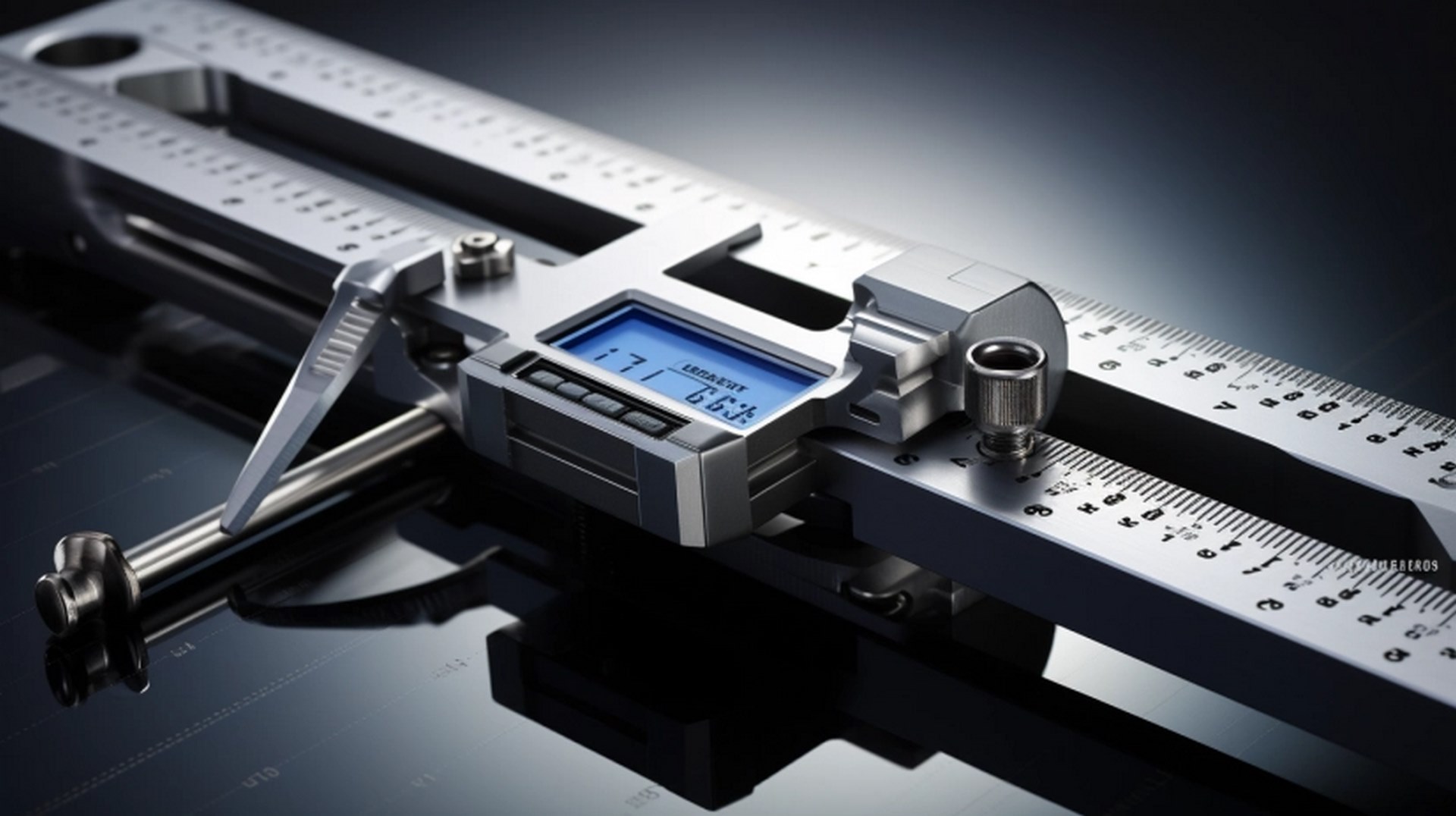

One important aspect to consider when determining the size of a bolt is its diameter, which can be measured using specialized tools. Bolt diameter refers to the thickness or width of the bolt shaft and is typically expressed in millimeters or inches. Accurate measurement of bolt diameter is crucial for selecting the appropriate hardware and ensuring proper fit within a given application. The most common tool used for measuring bolt diameter is a caliper, specifically a vernier caliper or digital caliper. These tools feature jaws that can be adjusted to fit around the shaft of the bolt, providing an accurate reading of its diameter.

In addition to measuring bolt diameter, it is equally important to accurately determine the length of a bolt. Bolt length refers to the distance from the underside of the head to the tip. This measurement ensures that bolts are long enough to securely fasten two components together without extending too far beyond what is necessary. Tools for measuring bolt length include rulers, tape measures, or specialized gauges designed specifically for this purpose.

Transitioning into the subsequent section about 'tools for measuring bolt length,' it becomes evident that while understanding how to measure bolt diameter is essential, knowing how to measure bolt length accurately complements this knowledge and facilitates successful assembly operations.

3. Tools for Measuring Bolt Length

Accurately determining the distance from the underside of the bolt head to its tip is facilitated by utilizing tools such as rulers, tape measures, or specialized gauges designed specifically for this purpose. These tools provide a precise measurement of the bolt length, ensuring accuracy in various applications.

In addition to rulers and tape measures, there are specialized gauges available that make measuring bolt length even easier. These gauges are designed with specific features to accurately measure the length of bolts in different sizes. Some common types of gauges include thread pitch gauges, which help determine the pitch or spacing between threads on a bolt, and digital calipers, which provide accurate measurements using electronic sensors.

To illustrate their effectiveness and functionality, consider the following table showcasing three commonly used tools for measuring bolt length:

| Tool | Description | Benefits |

|---|---|---|

| Ruler | Simple tool with marked units for measuring straight distances | Easy to use |

| Tape Measure | Flexible ribbon marked with units for measuring curved or linear paths | Versatile |

| Thread Pitch Gauge | Measures thread pitch and provides an accurate indication | Ensures proper fit and compatibility |

These tools not only facilitate accurate measurement but also enhance efficiency in various fields such as construction, engineering, automotive repair, and manufacturing processes.

Transitioning into the subsequent section about 'step-by-step guide to measure bolt length', it is important to understand how to properly utilize these tools for accurate measurements.

4. Step-by-Step Guide to Measure Bolt Length

To determine the distance from the underside of a bolt head to its tip, it is necessary to utilize specific tools and follow a step-by-step guide.

Firstly, ensure that you have a caliper or micrometer with sufficient measuring range and accuracy. The caliper should be set to measure in millimeters for precision. Place the bolt on a flat surface and adjust the caliper so that its jaws touch both the underside of the bolt head and the tip of the bolt. Take note of this measurement.

Next, remove any dirt or debris from the threads using a wire brush or compressed air. This will help provide an accurate measurement without interference. Gently screw a nut onto the threads until it reaches flush with the end of the bolt.

Now, use your caliper or micrometer again to measure from the underside of the bolt head to just below where the nut is located. Take note of this measurement as well.

By subtracting this second measurement from your initial length measurement, you can determine precisely how long your bolt is.

In conclusion, by utilizing appropriate tools and following these steps, you can accurately measure a bolt's length.

5. Tips for Accurate Bolt Measurement

When ensuring precise measurements of a bolt, it is important to consider factors such as the type of thread and the position of the nut. Accurate bolt measurement is crucial for various industries, including construction, automotive, and manufacturing.

To evoke an emotional response in the audience and emphasize the significance of accurate measurements, consider the following:

1. Safety: Proper bolt length ensures structural stability and prevents accidents or failures due to inadequate fastening.

2. Efficiency: Accurate measurements reduce time-consuming adjustments and rework, allowing for smoother assembly processes.

3. Cost-effectiveness: Precise bolt lengths minimize material waste by avoiding unnecessary cutting or purchasing additional bolts.

4. Reliability: Correctly measured bolts contribute to product longevity and customer satisfaction by ensuring optimal performance.

By understanding these emotional implications, professionals can fully grasp the importance of precise bolt measurement techniques. However, achieving accuracy requires avoiding common mistakes that may lead to incorrect measurements. Therefore, it is crucial to be aware of potential errors during the measuring process in order to ensure reliable results without compromising safety or efficiency.

One common mistake in determining the appropriate size of a fastening component relates to overlooking the role of thread engagement and its impact on overall stability. Thread engagement refers to the amount of overlap between the threads of a bolt and the corresponding threads in a tapped hole or nut. It is an essential factor to consider when measuring bolt length, as it directly affects the strength and stability of the joint.

Insufficient thread engagement can lead to a weak connection, increasing the risk of failure under load. On the other hand, excessive thread engagement can result in unnecessary stress concentration at both ends of the joint, potentially leading to premature fatigue failure. Therefore, it is crucial to determine an optimal thread engagement based on industry standards and guidelines.

To avoid this common mistake, proper measurement techniques should be employed. The length of a bolt should be measured from underneath its head to its tip, excluding any unthreaded portion or chamfer at either end. Additionally, consideration should be given to factors such as material thickness and potential adjustments for washers or other components.

Mikehardware- your trusted bolt supplier

In conclusion, measuring the length of a bolt is essential for various applications. By understanding the different types of bolts and common measurements, one can ensure accurate results.

Utilizing appropriate tools and following a step-by-step guide will aid in obtaining precise measurements. It is crucial to be mindful of common mistakes to avoid any inaccuracies.

Remember, accurately measuring bolt length not only ensures proper fit but also reflects attention to detail and commitment to quality workmanship.