How to Choose a Bolts and Nuts Factory?

Choosing the right bolts and nuts factory is of utmost importance in various industries. The selection process involves considering several factors, such as quality, reliability, and cost-effectiveness.

This article aims to provide guidance on how to make an informed decision when choosing a factory for bolts and nuts production. By examining case studies and industry best practices, readers will gain valuable insights into finding reliable suppliers in China and understanding the application of nuts and bolts in different industries.

Additionally, the article will explore the usual process for custom fasteners, ensuring readers are equipped with comprehensive knowledge in this field.

1. How important is it to choose a right bolts and nuts factory?

The importance of selecting a suitable bolts and nuts factory is a crucial factor to consider in ensuring the overall quality and performance of the manufactured products. Bolts and nuts are critical components used in various industries, such as automotive, construction, aerospace, and manufacturing. The quality and reliability of these fasteners directly impact the safety, durability, and functionality of the final products.

A reputable bolts and nuts factory adheres to strict quality control standards throughout the manufacturing process. They employ advanced technologies and machinery to produce high-quality products that meet industry specifications. These factories often have experienced engineers who monitor production processes, conduct rigorous testing procedures, and ensure compliance with international standards.

Choosing an appropriate factory also ensures consistent availability of bolts and nuts in required quantities. Timely delivery is essential to avoid project delays or disruptions in production schedules. A reliable supplier can provide on-time delivery without compromising product quality.

Furthermore, partnering with a reputable bolts and nuts factory allows for better customization options. They possess expertise in producing fasteners according to specific customer requirements. This flexibility enables manufacturers to design their products more efficiently while maintaining desired standards.

Considering these factors when choosing a bolts and nuts factory will help manufacturers make informed decisions that positively influence the overall quality of their manufactured goods.

2. Factors to Consider When Choosing a bolts and nuts factory

When choosing a bolts and nuts factory, several key factors need to be considered.

Firstly, product quality and professional certifications are crucial in ensuring that the factory produces high-quality products that meet industry standards.

Secondly, production capacity plays a significant role in determining if the factory can fulfill large orders and meet delivery deadlines.

Thirdly, customization options are essential for clients who require specific specifications or designs for their bolts and nuts.

Additionally, quality control measures implemented by the factory contribute to the overall reliability of their products.

Lastly, reputation and reviews provide valuable insights into the factory's track record and customer satisfaction levels, helping potential buyers make informed decisions.

2.1 Product Quality & Professional Certifications

To evaluate the quality of products and ensure professionalism, one may consider examining the factory's professional certifications. These certifications act as evidence that the factory adheres to certain standards and regulations in their manufacturing processes. By obtaining these certifications, factories demonstrate their commitment to producing high-quality products and maintaining a level of professionalism in their operations. Some commonly recognized certifications for bolts and nuts factories include ISO 9001:2015, ISO/TS 16949:2009, and AS9100D. These certifications signify compliance with quality management systems, automotive industry requirements, and aerospace industry standards respectively. A table summarizing these certifications along with their descriptions can be found below:

Certification | Description |

ISO 9001:2015 | Sets criteria for a quality management system |

ISO/TS 16949:2009 | Specifies requirements for automotive suppliers |

AS9100D | Focuses on aerospace industry requirements |

Considering these professional certifications is crucial in ensuring that the chosen factory is capable of meeting the required quality standards. Moving forward to evaluating production capacity...

2.2 Production Capacity

Considering the production capacity is essential for evaluating a factory's capability to meet the required demand and deliver products in a timely manner. Production capacity refers to the maximum output that a factory can achieve within a given time period. It depends on several factors, including machinery, labor force, and production processes.

A factory with high production capacity ensures that it can handle large orders efficiently, minimizing delays and backlogs. Additionally, factories with higher production capacities are often more reliable in terms of product availability and delivery timelines.

Moreover, a robust production capacity allows factories to scale their operations based on market demands effectively. This transition towards customization is crucial as it allows factories to cater to specific customer requirements while maintaining efficient production levels without compromising quality or delivery timelines.

2.3 Customization

This discussion will focus on two key points when choosing a bolts and nuts factory: material selection and quantity options.

Material selection is an important factor to consider as it determines the strength, durability, and corrosion resistance of the bolts and nuts. Factors such as the application requirements, environmental conditions, and budget constraints should be taken into account when selecting the appropriate material.

Additionally, quantity options are crucial in ensuring that the chosen factory can accommodate specific production volumes to meet demand efficiently without compromising quality.

Contact us for a free quote of your customizing bolts and nuts!

Material Selection

One important factor to consider when selecting a bolts and nuts factory is the choice of materials used in their production. The quality and durability of bolts and nuts largely depend on the materials from which they are made. Different materials offer varying strengths, corrosion resistance, and temperature tolerance. For instance, stainless steel provides excellent corrosion resistance while alloy steel offers high tensile strength. A comparison of material options is presented in the following table.

Material | Strength | Corrosion Resistance | Temperature Tolerance |

Stainless Steel | High | Excellent | Moderate |

Alloy Steel | Very High | Good | High |

Carbon Steel | High | Fair | Moderate |

Brass | Low | Excellent | Low |

Considering the appropriate material for your specific application is crucial to ensure optimal performance and longevity of the bolts and nuts.

Additionally, it is important to explore quantity options available at different suppliers.

Quantity Options

An important aspect to examine when evaluating suppliers is the range of quantity options available for purchase. This factor is crucial as it allows businesses to meet their specific needs and manage inventory efficiently. Suppliers that offer a wide range of quantity options provide flexibility in meeting fluctuating demand, reducing the risk of overstock or stockouts.

In addition, having multiple quantity options enables businesses to negotiate better pricing based on economies of scale. Once the appropriate quantities are determined, the next consideration is ensuring proper quality control measures are in place.

2.4 Quality Control

To ensure the quality of bolts and nuts produced by a factory, it is essential to implement rigorous quality control measures throughout the manufacturing process. This ensures that the final products meet industry standards and customer expectations.

Here are four key elements of effective quality control in bolt and nut factories:

- Regular inspections: Factory inspectors should conduct routine checks to identify any defects or deviations from specifications during production.

- Testing equipment: The use of advanced testing equipment, such as tensile strength testers and hardness testers, helps verify the mechanical properties of bolts and nuts.

- Traceability systems: Implementing traceability systems allows for easy identification of raw materials used in production, ensuring their compliance with quality standards.

- Employee training: Properly trained employees understand the importance of quality control and follow established procedures to maintain consistent product quality.

2.5 Reputation and Reviews

This discussion focuses on the importance of project success, customer reviews, and testimonials in evaluating a company's reputation.

Project success is a key indicator of a company's ability to deliver high-quality products or services.

Customer reviews and testimonials provide valuable insights into the experiences and satisfaction levels of previous clients, which can help potential customers make informed decisions about whether to engage with the company.

Project Success

Project success can be determined by various factors such as adherence to timelines, meeting quality standards, and achieving desired outcomes. To ensure project success, a bolts and nuts factory should:

- Establish clear project goals and objectives.

- Develop a comprehensive project plan with defined tasks and milestones.

- Allocate resources effectively to meet project requirements.

- Monitor progress regularly and make necessary adjustments to stay on track.

By considering these factors, customers can evaluate the factory's ability to deliver successful projects.

This evaluation is further reinforced by customer reviews and testimonials, which provide additional insight into the factory's past performance and overall satisfaction of its clients.

Customer Reviews and Testimonials

Customer reviews and testimonials provide valuable feedback about the performance and satisfaction of the factory's projects, serving as a reliable source for evaluating its track record. These reviews highlight the strengths and weaknesses of the factory's products, customer service, and overall experience. They allow potential customers to gauge the factory's credibility and reliability. Below is an example table summarizing some key points from customer reviews:

Positive Feedback | Negative Feedback |

1. High-quality products | 1. Delays in delivery |

2. Excellent customer service | 2. Lack of communication |

3. Competitive pricing | 3. Issues with product durability |

Understanding these insights can help in making an informed decision when choosing a bolts and nuts factory.

Moving on to pricing and payment terms...

2.6 Pricing and Payment Terms

When considering a bolts and nuts factory, it is important to evaluate the pricing and payment terms offered by potential suppliers. This step is crucial in order to ensure that the chosen factory offers competitive prices and favorable payment conditions.

Here are four key factors to consider when assessing pricing and payment terms:

- Price competitiveness: Compare the prices offered by different suppliers to determine if they are reasonable and in line with market standards.

- Bulk discounts: Inquire whether the supplier offers discounts for larger orders or long-term contracts, as this can significantly impact overall costs.

- Payment flexibility: Assess whether the supplier accepts various forms of payment, such as credit cards or bank transfers, to accommodate your preferred method.

- Payment terms: Evaluate the proposed payment terms, including down payments and installment options, to ensure they align with your financial capabilities.

By carefully evaluating these aspects of pricing and payment terms, you can make an informed decision when choosing a bolts and nuts factory for your needs.

The next section will discuss another important aspect of selecting a factory - logistics and shipping arrangements.

2.7 Logistics and Shipping

Logistics and shipping arrangements play a crucial role in the overall efficiency and effectiveness of the supply chain management process. Timely delivery of products is essential to meet customer demand and maintain customer satisfaction. The table below provides an overview of key considerations when evaluating logistics and shipping options for a bolts and nuts factory.

Consideration | Description | Example |

Transportation Mode | Selecting the appropriate mode of transportation based on cost, speed, reliability, and product characteristics. | Air freight for urgent shipments or ocean freight for bulk orders. |

Freight Forwarders/Carriers | Evaluating different freight forwarders or carriers based on their reputation, network coverage, pricing, tracking capabilities, and customer service. | DHL, FedEx, Maersk Line. |

Warehousing Facilities | Assessing warehousing facilities to ensure they are strategically located, well-maintained, secure, and equipped with modern inventory management systems. | Temperature-controlled warehouses for perishable goods or bonded warehouses for duty-free storage. |

Efficient logistics and shipping processes contribute to timely order fulfillment while minimizing costs and ensuring product integrity during transit. After considering these factors in selecting a suitable logistics provider, attention can then be directed towards after-sales services to further enhance customer satisfaction.

2.8 After-sales Service

One important aspect to consider in the supply chain management process is the provision of after-sales services, which can further enhance customer satisfaction and loyalty. After-sales services refer to the support and assistance provided to customers after they have made a purchase. This includes activities such as product installation, maintenance, repair, and warranty services. Effective after-sales services can greatly impact customer perception of a company's commitment to quality and their overall experience with the product.

Here are four key areas that should be considered when evaluating the quality of after-sales services:

- Responsiveness: How quickly does the company respond to customer inquiries or issues?

- Expertise: Does the company have knowledgeable staff who can effectively address customer concerns?

- Accessibility: Are there multiple channels through which customers can reach out for assistance?

- Flexibility: Does the company offer customized solutions based on individual customer needs?

Understanding these factors will help in assessing where one can find reliable bolts and nuts factories without compromising on after-sales service quality.

3. Where can I find reliable bolts and nuts factories?

A comprehensive search of industrial directories and online platforms provides a wide range of options for locating reliable bolts and nuts factories. Industrial directories, such as Thomasnet and Alibaba, offer extensive databases that allow users to search for suppliers based on specific criteria such as location, certifications, and production capabilities. These directories provide detailed information about each supplier, including their contact details, product offerings, and customer reviews.

Online platforms like Global Sources and Made-in-China also serve as valuable resources for finding reputable bolts and nuts factories. These platforms host a large number of suppliers from various industries, making it easier to compare different options.

Additionally, trade shows and exhibitions related to the manufacturing industry can be excellent opportunities to connect with potential suppliers. By attending these events, buyers can meet face-to-face with representatives from various bolts and nuts factories. This allows them to ask questions directly, assess the quality of products on display, and establish personal connections with suppliers.

4. Who is the supplier of bolts and nuts in China?

Bulk Fasteners from Mikehardware - Your Trusted Fastener Supplier

When choosing a manufacturing partner, consider Dongguan Mike Hardware, specialists in crafting precision hardware tailored to your needs. Our expertise spans a wide array of products, including screws, CNC parts, and various materials like copper, aluminum, stainless steel, and carbon steel.

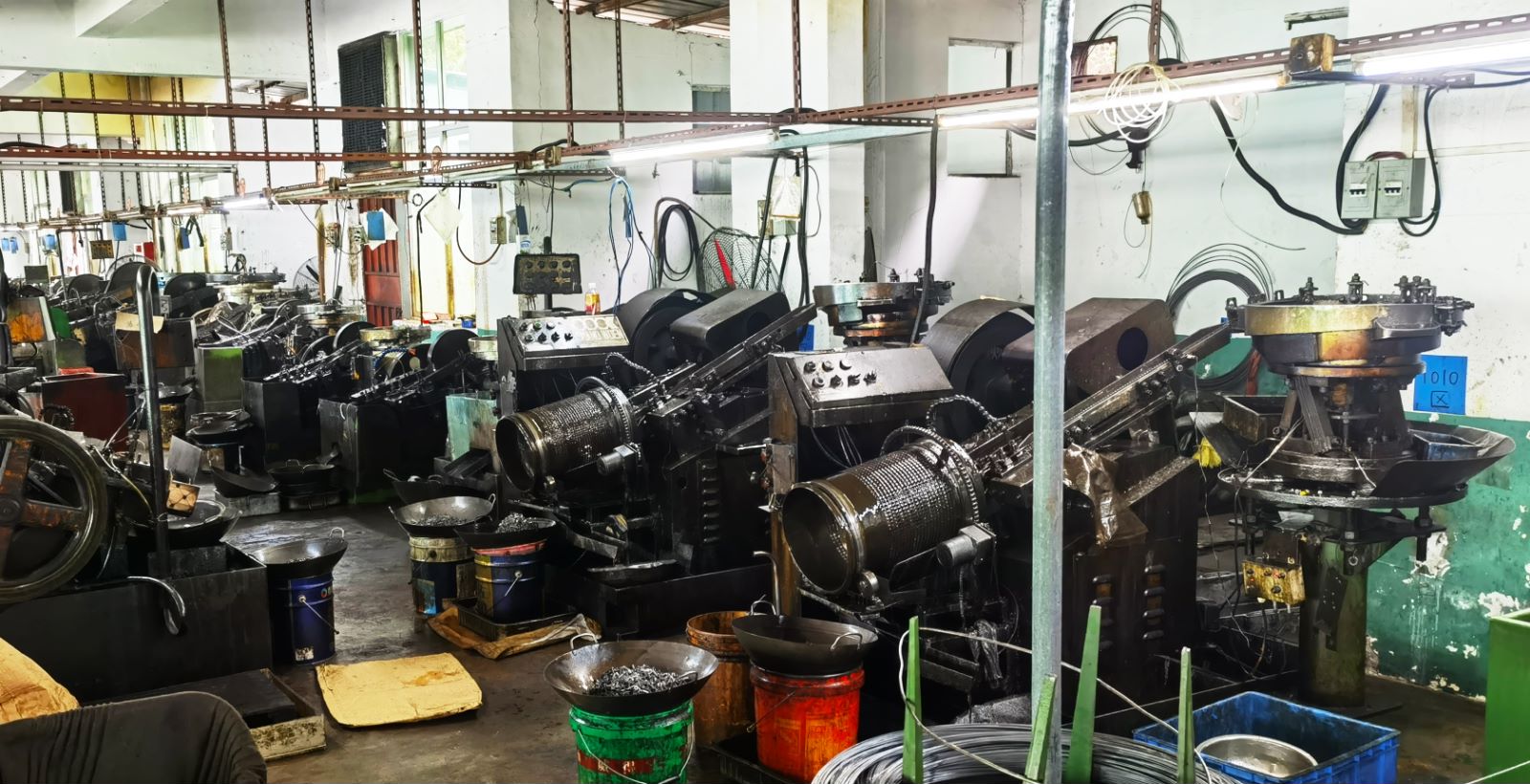

With a robust arsenal of over 100 top-tier imported screw manufacturing machines and cutting-edge testing equipment, we ensure quality and precision in every project. Additionally, our extensive experience of over a decade in CNC parts production is backed by a team of more than 50 seasoned technical experts, each with two decades of industry experience. From design, mold creation, polishing, CNC processing, to service treatment, we offer a comprehensive, one-stop solution.

Moreover, our mold manufacturing team boasts over 15 years of experience, providing personalized, one-on-one project guidance. Our wide range of precision equipment expedites production schedules, often outpacing competitors by 2 to 7 days. This efficiency translates to cost savings for our valued customers. At Dongguan Mike Hardware, we stand ready to be your trusted manufacturing partner, welcoming collaborations with partners and customers worldwide."

Contact us bulk buy bolts and nuts at a right price!

Now let's explore what industries rely on nuts and bolts without mentioning 'step'.

5. What industry are nuts and bolts used in?

The previous subtopic discussed the suppliers of bolts and nuts in China. Now, let us explore the industries in which these essential fasteners find applications. Nuts and bolts are extensively used across various sectors for connecting, securing, or joining different components or structures together. The table below provides an overview of some key industries where nuts and bolts play a crucial role:

Industry | Application |

Construction | Fastening structural elements like beams and columns |

Automotive | Assembling engines, chassis, and other parts |

Aerospace | Joining aircraft components |

The construction industry relies on nuts and bolts to secure critical structural elements such as beams and columns. In the automotive sector, these fasteners are instrumental in assembling engines, chassis, and various other parts. Similarly, in the aerospace industry, nuts and bolts are vital for joining intricate aircraft components.

Understanding the diverse applications of nuts and bolts is essential when choosing the right ones for your specific needs. So now let's move on to discussing how to choose suitable nuts and bolts without explicitly using 'step'.

6.How do you choose nuts and bolts?

To make informed decisions in selecting appropriate fasteners, one must consider factors such as material compatibility, load requirements, and environmental conditions. Considering these factors ensures that the chosen nuts and bolts will effectively perform their intended function.

- Material Compatibility: The materials of the fasteners should be compatible with the materials of the joint being assembled. This includes considering factors such as galvanic corrosion potential between dissimilar metals.

- Load Requirements: The load capacity of the fasteners should match or exceed the anticipated loads that will be applied to them. This involves considering factors such as tensile strength, shear strength, and torque requirements.

- Environmental Conditions: The environmental conditions in which the fasteners will be used should be taken into account. Factors such as exposure to moisture, temperature fluctuations, or corrosive substances can affect the durability and performance of nuts and bolts.

- Size and Design: The size and design of the fasteners should align with the specific application requirements. This includes considerations like thread type (e.g., coarse or fine), head type (e.g., hexagonal or Phillips), and length.

Considering these factors when choosing nuts and bolts ensures that they are suitable for their intended use, which promotes secure assembly and long-term reliability.

The usual process for custom fasteners involves a series of steps from initial design specifications through manufacturing to final inspection before delivery to customers without compromising quality standards.

7. What is the usual process for custom fasteners?

One common procedure for producing custom fasteners involves a sequential set of stages, starting from initial design specifications and progressing through manufacturing until final inspection is performed prior to customer delivery.

The process begins with the design phase, where engineers work closely with customers to determine the specific requirements for the fasteners. This includes factors such as size, material composition, and performance characteristics. Once the design specifications are finalized, the manufacturing stage begins.

In the manufacturing stage, raw materials are selected based on the desired properties of the fasteners. These materials can include various types of metal alloys or non-metallic substances depending on the application. The chosen materials are then processed using various techniques such as forging, machining, or casting to shape them into the desired form. Additional processes like heat treatment may also be employed to enhance their strength and durability.

After manufacturing, a thorough inspection is carried out to ensure that each fastener meets all required specifications and quality standards. This inspection typically involves visual checks, dimensional measurements, and mechanical testing to verify factors such as hardness and tensile strength.

Once all inspections have been completed successfully, the custom fasteners are ready for delivery to the customer. This sequential process ensures that every step is carefully executed in order to produce high-quality custom fasteners that meet customer expectations and industry standards.

In conclusion, selecting the appropriate bolts and nuts factory plays a paramount role in ensuring quality and reliability. Considering crucial factors such as expertise, experience, and equipment is essential when making this decision.

Additionally, locating trustworthy factories can be accomplished through thorough research and seeking recommendations. China stands as a prominent supplier in this industry.

Nuts and bolts find application across various industries where their selection should be based on specific requirements. Understanding the process for custom fasteners aids in obtaining tailored solutions for individual needs.

Ultimately, meticulous deliberation guarantees fruitful outcomes in choosing a bolts and nuts factory.