A Comprehensive Guide to Industrial Fasteners Manufacturers

Industrial fasteners play a crucial role in various sectors, symbolizing the strength and stability of mechanical connections. This comprehensive guide aims to provide an objective, impersonal overview of industrial fasteners manufacturers.

It will explore the definition of industrial fasteners and their significance in Original Equipment Manufacturer (OEM) applications. Additionally, it will discuss different types of industrial fasteners and their specific uses, emphasizing the importance of choosing the right manufacturer.

Finally, it will offer a list of reputable manufacturers and highlight Mikehardware as a trusted source for customizable fastener solutions.

1. What are industrial fasteners?

Industrial fasteners are hardware devices used to mechanically join or affix two or more objects together. They play a crucial role in various industries, including automotive, construction, aerospace, and manufacturing. These fasteners come in a wide range of shapes, sizes, and materials to accommodate different applications and requirements.

Common types of industrial fasteners include bolts, screws, nuts, washers, rivets, and pins. Bolts are threaded rods with a head on one end that is used with a matching nut to secure objects together. Screws have threads along their entire length and are typically used to hold objects in place by creating friction between the screw threads and the material being joined. Nuts are internally threaded components that mate with bolts or screws to provide a secure connection.

Washers are thin disks placed under the head of a bolt or nut to distribute the load evenly over a larger surface area and prevent damage to the connected objects. Rivets are permanent fasteners consisting of a cylindrical shaft with heads on both ends that can be deformed using heat or pressure to create a strong joint. Pins are cylindrical rods that pass through aligned holes in two or more objects to hold them together.

These industrial fasteners serve as essential components for ensuring structural integrity and reliability in various applications.

Now let's explore another type of fastener commonly encountered: OEM fasteners.

2. What are OEM fasteners?

Originating from the term Original Equipment Manufacturer, OEM fasteners refer to the specialized components produced by a specific manufacturer for use in various products and equipment. These fasteners play a crucial role in ensuring the structural integrity and functionality of diverse applications across industries.

To better understand OEM fasteners, consider the following:

- Manufacturers: Leading companies that specialize in producing OEM fasteners include well-established names such as Fastenal, Wurth Group, ITW (Illinois Tool Works), Stanley Black & Decker, and Bulten AB.

- Product Range: These manufacturers offer an extensive range of OEM fasteners, including screws, bolts, nuts, washers, rivets, pins, and clips.

- Customization: Manufacturers often provide tailored solutions by offering customized designs or materials based on customer requirements.

3. Types of Industrial Fasteners

Categorizing industrial fasteners is essential for understanding their diverse applications and ensuring the proper selection and usage in various products and equipment. Industrial fasteners can be broadly classified into several types based on their design, function, and material composition. The most common types include screws, bolts, nuts, washers, rivets, pins, clips, and anchors.

Screws are threaded fasteners that are used to hold objects together by creating a strong bond between surfaces. Bolts are similar to screws but usually have no pointed end and require a nut to secure them in place. Nuts are internally threaded components that mate with bolts or screws to provide a secure joint. Washers act as spacers or distribute loads over a larger surface area to prevent damage or loosening of the joint.

Rivets are permanent fasteners that join two or more materials together by deforming the rivet body. Pins are cylindrical fasteners used for alignment or securing purposes. Clips are commonly used for holding wires or cables in place. Anchors provide stability by securing objects to concrete or other solid structures.

Understanding the different types of industrial fasteners is crucial for selecting the appropriate one based on specific requirements such as load-bearing capacity, corrosion resistance, temperature tolerance, and environmental factors. This knowledge will enable engineers and manufacturers to make informed decisions regarding the choice of fastener for different applications without compromising performance or safety considerations.

4. What are industrial fasteners used for?

The applications of industrial fasteners encompass a wide range of sectors, including construction, automotive, aerospace, electronics, and manufacturing industries. Industrial fasteners are essential components that play a crucial role in the assembly and joining of various materials. They are used to securely hold together different parts or structures, ensuring stability and reliability.

The following are some common uses of industrial fasteners:

- In construction:

- Fastening structural elements such as beams, columns, and trusses.

- Installing roof panels, wall claddings, and flooring systems.

- In automotive:

- Securing engine components like cylinder heads and pistons.

- Attaching body panels and interior fixtures.

- In aerospace:

- Assembling aircraft structures and fuselage sections.

- Connecting wings, tail assemblies, and landing gear components.

- In electronics:

- Mounting circuit boards onto chassis or enclosures.

- Fixing wires and cables in place to ensure proper connections.

- In manufacturing industries:

- Joining machinery parts for efficient operation.

- Holding together various equipment during production processes.

Choosing the right industrial fastener manufacturer is crucial to ensure quality products that meet specific requirements. Selecting a reliable manufacturer guarantees the use of high-grade materials with precise dimensions that comply with industry standards. Additionally, experienced manufacturers provide technical support and guidance to help customers select the most suitable fasteners for their applications.

5. Importance of Choosing the Right Fasteners Manufacturer

Selecting a reputable manufacturer is essential to ensure the quality and suitability of fasteners for specific applications. The choice of a reliable manufacturer directly affects the overall performance, durability, and safety of industrial fasteners. A reputable manufacturer will adhere to industry standards and regulations, employ stringent quality control measures, and use high-quality materials in their production processes. Additionally, they will have a proven track record of delivering products that meet customer specifications.

To emphasize the importance of selecting the right manufacturer, consider the following table:

Factors | Importance | Emotional Response |

Quality | High | Trust |

Reliability | High | Confidence |

Experience | Medium | Assurance |

The table highlights the emotional responses associated with each factor. Quality evokes trust in the product's performance, reliability instills confidence in its functionality under various conditions, while experience provides assurance that the manufacturer has successfully produced similar products before.

Considering these emotional responses can guide decision-making when selecting an industrial fastener manufacturer. By understanding their significance in terms of quality, reliability, and experience, potential buyers can make informed decisions that align with their specific requirements.

This emphasizes the need to carefully evaluate potential manufacturers by asking relevant questions about their capabilities and processes.

6. Questions to Ask Potential Industrial Fasteners Manufacturers

Evaluating potential suppliers involves asking relevant questions about their production capabilities and quality control processes. To ensure that you choose the right industrial fasteners manufacturer for your needs, consider asking the following questions:

- Production capabilities:

- What is your production capacity? Can you meet our demand?

- Do you have the necessary equipment and technology to produce a wide range of fasteners?

- Quality control processes:

- How do you ensure the quality of your products?

- Do you have any certifications or quality management systems in place?

By asking these questions, you can gain valuable insights into a supplier's ability to meet your requirements and deliver high-quality products consistently. Understanding their production capabilities will allow you to assess whether they can handle your order volume, while knowledge of their quality control processes will give you confidence in the reliability of their products.

Transitioning into the subsequent section about 'industrial fasteners manufacturers list,' it is essential to gather information on multiple potential suppliers before making a decision. This list will provide an overview of reputable manufacturers in the industry, allowing you to further evaluate them based on specific criteria.

7. Industrial fasteners manufacturers list

Some well-known industrial fasteners manufacturers as of my last update include:

- Fastenal

- McMaster-Carr

- Grainger

- MSC Industrial Supply

- Penn Engineering & Manufacturing Corp.

- Acme Industrial

- Arconic Fastening Systems & Rings

- Nucor Fastener

- Alcoa Fastening Systems & Rings

- Bulten

- Earnest Machine Products

- PCC Fasteners

- STANLEY Engineered Fastening

- TriMas Corporation

- Würth Group

8. How to choose the Best industrial fasteners manufacturers

One crucial aspect in identifying the top manufacturers in the industry is evaluating their reputation and performance. When it comes to industrial fasteners, there are several key players that consistently stand out among the rest. Here are some reasons why these manufacturers are considered the best:

- Quality and Reliability: These top manufacturers prioritize quality control measures to ensure that their fasteners meet or exceed industry standards. They use high-quality materials and employ rigorous testing processes to guarantee reliability.

- Stringent Quality Control: The top manufacturers have robust quality control systems in place, including regular inspections, strict adherence to specifications, and comprehensive testing procedures.

- Compliance with Standards: They comply with international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management systems.

- Innovation and Technology: Leading manufacturers constantly invest in research and development to stay ahead of market trends. They leverage cutting-edge technology to enhance product performance, increase efficiency, and improve customer experience.

- Advanced Manufacturing Techniques: These manufacturers utilize advanced machinery, automation, and computerized systems for precise manufacturing processes.

- Product Development: The best manufacturers continuously innovate by introducing new designs or improving existing ones based on customer feedback and evolving industry requirements.

When looking for a trusted fastener manufacturer that offers customized solutions, mikehardware is a reliable choice. With their expertise in producing tailored fasteners according to specific requirements, customers can rely on their commitment to delivering high-quality products efficiently.

9. Customize Fasteners from Mikehardware - Your Trusted Fastener Manufacturer

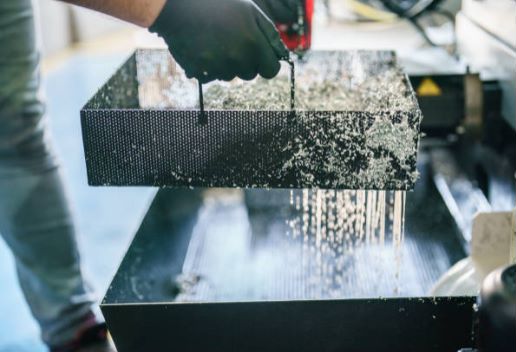

Dongguan Mike Hardware Co., Ltd. is your trusted partner for CNC product manufacturing. With over a decade of experience and a team of over 50 skilled professionals, we bring two decades of industry expertise to the table. We offer comprehensive one-stop production solutions, starting from mold design and continuing through CNC processing and surface treatment. Our state-of-the-art facility is home to more than 350 proficient operators, ensuring seamless execution of projects.

Backed by 15 experienced mold designers, we provide personalized project follow-up using advanced 2D and 3D technology, resulting in an impressive 98% product completion rate. Our mold manufacturing team, with 15 years of experience, offers tailored project support and quick mold openings in just 2-7 days, helping you save costs without compromising on quality.

Contact us for a quote of wholesale fasteners!

In conclusion, industrial fasteners play a crucial role in various industries. It is important to choose the right manufacturer to ensure quality and reliability. Asking the right questions can help in making an informed decision.