How to Choose the Right CNC Machine Parts Factory for Your Project

Choosing the right CNC machine parts factory for your project is a critical decision that can greatly influence the success of your operation.

It is not merely a matter of selecting a factory that can deliver parts; rather, it involves a comprehensive analysis of various factors such as understanding your project needs, evaluating the technical capabilities of potential factories, the importance of quality assurance, assessing delivery and service, as well as cost-effectiveness.

As we venture into this discussion, you will find that each of these elements plays a pivotal role in making an informed choice, which ultimately could be the difference between project success and failure.

Key Takeaways

- Prioritize factory reliability and technical expertise in CNC machining to ensure optimal performance and efficiency.

- Emphasize the importance of quality assurance and control mechanisms to maintain consistent precision in production processes.

- Evaluate track record, packaging standards, and communication efficiency for reliable delivery, service, and contingency planning.

- Focus on cost-effectiveness through budget analysis, negotiation of pricing models, and establishment of long-term partnerships for sustainable affordability and quality.

Understanding Your Project Needs

In the realm of CNC machining, comprehending the specific requirements of your project is a fundamental step in selecting an optimal parts factory. This understanding will not only streamline the production process but also ensure the quality and efficiency of the final product.

The first element to consider is the project timeline, which becomes paramount in maintaining control over the project's progression. A clear timeline sets accurate expectations for deliverables, allowing you to choose a parts factory that can meet these deadlines without compromising on quality.

Equally significant is the aspect of material compatibility. CNC machining involves the use of diverse materials, each with its unique properties and machining requirements. It's crucial to identify a parts factory that can handle your chosen material, ensuring the durability and functionality of the finished product.

Evaluating Technical Capabilities

Having determined your project needs and material compatibility, it becomes essential to assess the technical capabilities of potential CNC machine parts factories. This is a critical step to ensure that the factory can meet your project specifications and timelines, as well as maintain the quality and reliability of the produced parts.

In evaluating the technical capabilities, consider these factors:

- Factory reliability: Look for a factory with a proven track record of delivering high-quality parts on time. This demonstrates their ability to handle complex projects and deliver consistent results.

- Machine maintenance: Regular maintenance of CNC machines is vital to ensure their optimal performance and longevity. Factories that prioritize machine maintenance are likely to produce high-quality parts.

- Technical expertise: The factory should have skilled workers who understand the nuances of CNC machining and can handle potential problems.

- Advanced technology: Factories using the latest CNC technology will be more efficient and accurate, which can save time and costs.

- Quality control: A robust quality control system indicates that the factory is dedicated to producing high-quality parts and can catch and correct errors early.

Choosing a factory with strong technical capabilities will give you more control over your project's outcome and ensure its success.

Importance of Quality Assurance

Undoubtedly, Quality Assurance plays a pivotal role in selecting a CNC machine parts factory, serving as the cornerstone of consistent performance and customer satisfaction. The assurance of quality is not an option but a necessity in the precision-demanding industry of CNC machining. This assurance is typically achieved through robust inspection protocols and relevant supplier certifications.

Inspection protocols ensure that each part produced is checked for quality and conformance to specifications. They provide a systematic approach, eliminating possible errors and inconsistencies. On the other hand, supplier certifications act as proof of a factory's commitment to quality, validating their processes and abilities.

To evoke emotion, let's consider the following table:

| Quality Aspect | Impact |

|---|---|

| Inspection Protocols | Ensures conformance, eliminates errors |

| Supplier Certifications | Validates abilities, proves commitment to quality |

In a field where precision is paramount, the importance of Quality Assurance cannot be overstated. It provides the control you desire when outsourcing your project. By choosing a CNC machine parts factory with stringent quality assurance measures, you ensure that your project will meet the highest standards of precision and quality.

Assessing Delivery and Service

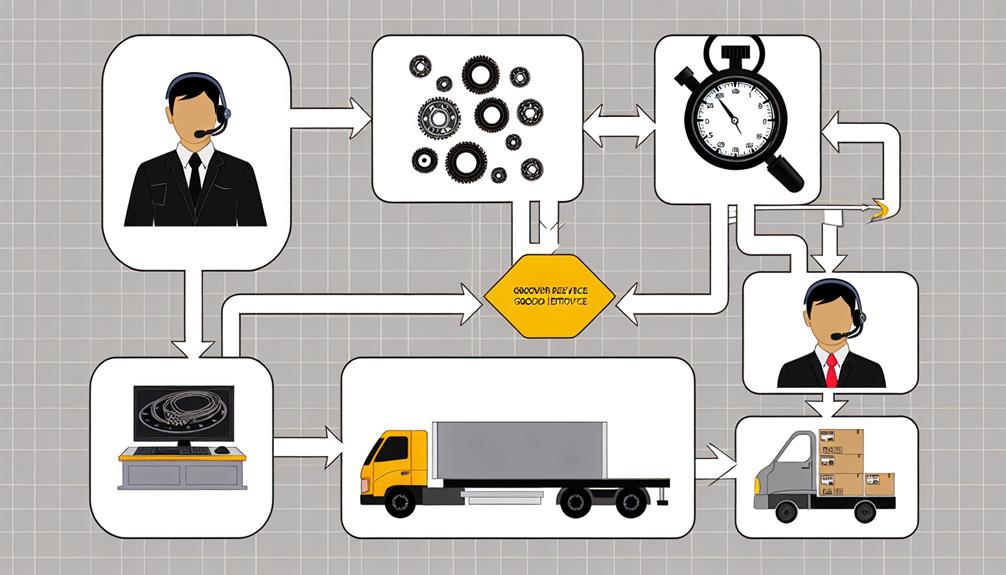

Timeliness and service reliability form another critical dimension to consider when selecting a CNC machine parts factory. The capacity of a factory to deliver on time and provide reliable service has a direct impact on your project timeline and overall quality.

To assess these aspects effectively, consider the following:

- Track Record: Evaluate the factory's historical performance on punctuality and service consistency.

- Packaging Standards: The quality of packaging reflects the factory's professionalism and commitment to product safety during transit.

- Communication Efficiency: A reliable partner should be able to communicate effectively, promptly responding to queries and providing regular updates.

- Contingency Planning: Understand the factory's strategies for handling unexpected delays or complications. A robust plan ensures continuity and reliability.

- Customer Reviews and References: Feedback from previous clients can provide valuable insights into the factory's service and delivery capabilities.

These factors are crucial for maintaining control over your project and ensuring it progresses smoothly. Remember, a reliable CNC machine parts factory should not only produce high-quality parts but also exhibit excellent service and timely delivery.

Consideration of Cost Effectiveness

Another pivotal factor to weigh in when choosing a CNC machine parts factory is the cost-effectiveness of their products and services. A factory that offers affordable yet high-quality parts will give you the most value for your money. This, however, requires meticulous budget analysis and financial planning on your part.

To begin with, lay out your project's budget and financial expectations. Consider all potential costs, including material, labor, shipping, and possible adjustment expenses. Once you have a clear understanding of your budget, you can negotiate with the factory for a pricing model that aligns with your financial plan.

Next, carefully scrutinize the factory's pricing structure. Make sure there are no hidden costs that could potentially upset your budget. Assess the ratio of the cost to the quality of the parts. A lower price may not always be cost-effective if it compromises the quality and longevity of the parts.

Lastly, take into account the potential for long-term partnerships. A factory that offers competitive pricing and consistently delivers high-quality parts is worth considering for repeat business. This way, you can ensure cost-effectiveness not just for a single project, but for future endeavors as well.

Frequently Asked Questions

What Are the Environmental Policies of the CNC Machine Parts Factory?

Investigate the factory's environmental policies thoroughly. Ensure policy transparency and adherence to sustainable practices. Evaluate their waste management, energy efficiency measures, and commitment towards reducing environmental impact. This will provide control over your project's environmental footprint.

How Does the Factory Handle CNC Machine Parts Disposal or Recycling?

The factory prioritizes environmentally responsible disposal methods, ensuring waste minimization. They engage in robust recycling initiatives, judiciously repurposing CNC machine parts, thereby contributing to sustainable manufacturing practices and control over environmental impact.

Does the Factory Provide Any After-Sales Services or Warranties on the Machine Parts?

Evaluating after-sales services is crucial. Ascertain the service quality and warranty duration offered by the factory. A comprehensive warranty indicates confidence in their parts, ensuring your project's continuity and control over potential disruptions.

What Type of Training or Qualifications Do the Factory Workers Handling CNC Machine Parts Have?

The factory employs highly trained workers proficient in CNC operations, ensuring worker safety and quality assurance. Their rigorous training and qualifications are crucial in maintaining the high standards of the factory's output.

Can the Factory Customise Machine Parts According to Specific Project Requirements?

Yes, a well-equipped factory can customise CNC machine parts to meet specific project requirements, considering factors like material compatibility and production capacity. Customisation ensures the parts align perfectly with your project's unique specifications.

Mikehardware-your trusted cnc machined parts manufacturer

In conclusion, the process of selecting an apt CNC machine parts factory requires meticulous understanding of project needs, careful evaluation of technical capabilities, and diligent assessment of quality assurance, delivery, and service.

A balance between these factors and cost-effectiveness ensures a successful partnership. Therefore, the importance of this choice should not be underestimated, as it directly impacts the overall project outcome, potentially leading to remarkable success or significant setback.

At Dongguan Mike Hardware Co., Ltd., precision engineering meets innovation, delivering impeccable CNC product manufacturing solutions. Explore our array of customized fasteners, screws, and coatings, ensuring your projects excel in performance, precision, and quality.

Contact us for a free quote of your ideal cnc machined parts.