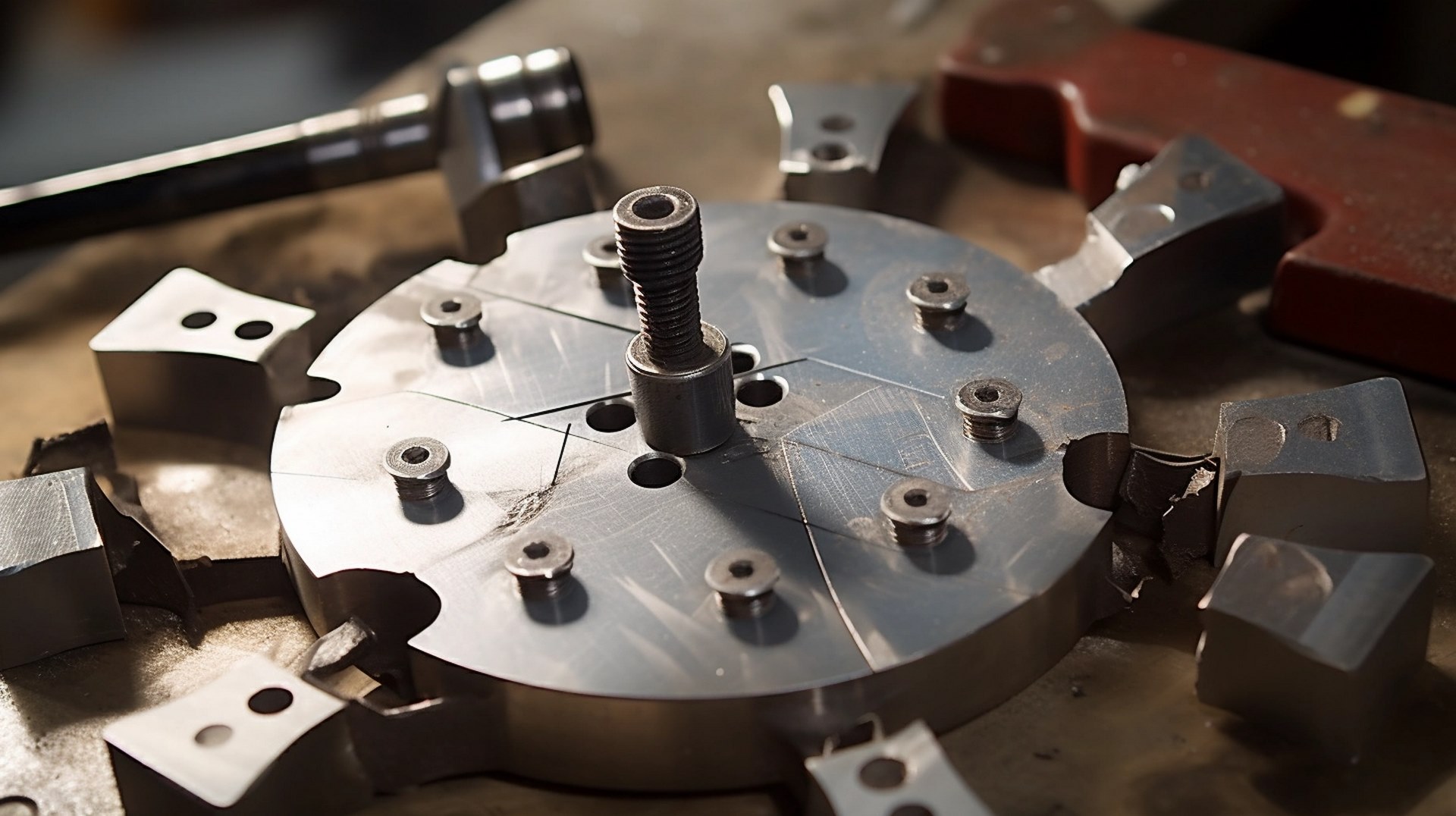

Custom Screws And Bolts

Custom screws and bolts are specialized fasteners that are designed to fit specific applications. They offer a number of advantages over standard off-the-shelf screws, such as improved strength, greater durability, higher performance, and better overall reliability. In addition, custom screws and bolts can be produced in a range of materials, sizes, and thread types to meet the needs of any project. This article will provide an overview of the benefits of using custom screws and bolts, the types of screws and bolts available, and considerations when selecting the right fastener for a job.

Key Takeaways

- Custom screws and bolts offer strong bonding and corrosion resistance, making them ideal for use in electronics and other applications where micro-parts need to be securely fastened.

- By optimizing production materials and processes, utilizing 3D printing technology, and reusing existing parts, manufacturers can reduce waste and improve sustainability.

- Using custom screws and bolts can enhance productivity by ensuring proper fit, reliable performance, and time and resource savings on assembly and rework.

- Custom screws and bolts have a long service life due to their corrosion resistance, durability in extreme conditions, and low maintenance requirements, resulting in cost savings and reduced downtime.

1. The Benefits of Using Custom Screws and Bolts

Custom screws and bolts provide numerous benefits in electronics manufacturing, such as strong bonding of micro-parts, facilitating repair and replacement, reducing waste in production, enhancing productivity, and providing long service life.

Strong Bonding of Micro-Parts in Electronics

The use of custom screws and bolts is essential for strong bonding of micro-parts in electronics, providing numerous benefits. The precision of custom screws and bolts allows for secure installation of components without damaging delicate parts.

Corrosion Resistant Coatings: Specialized coatings can be applied to custom screws and bolts to ensure resistance to rust and corrosion.

Heat Treated Metals: Custom screws and bolts can be made from heat-treated metals for improved strength and durability.

Threading Techniques: Using specific threading techniques can further improve the precision of custom screws and bolts, making them ideal for connecting micro-parts in electronics.

Custom screws and bolts offer higher levels of control and accuracy, making them the ideal choice for strong bonding of micro-parts in electronics. With the right threading techniques and corrosion resistant coatings, custom screws and bolts can provide reliable and secure installation of components.

Facilitates Repair and Replacement

One of the primary benefits of using custom screws and bolts is the ease of repair and replacement. Custom screws and bolts can provide a better fit, more efficient installation, improved accuracy, and cost savings. This makes it easier to identify the right size and type of fastener for any repair or replacement job. The improved accuracy ensures that the screws and bolts fit precisely, making repairs and replacements faster and more reliable. The cost savings achieved by using custom screws and bolts also make it a more cost-effective solution than buying standard-sized fasteners. Overall, custom screws and bolts make repair and replacement jobs easier and more cost-effective, while providing improved accuracy and reliability.

Reduction of Waste in Manufacturing

By using custom screws and bolts, manufacturers can often reduce waste in their production processes, minimizing costs, environmental impacts, and improving production efficiency. These benefits can be achieved in various ways:

- In the design phase:

- Designing custom screws and bolts to suit specific requirements allows for the optimization of production materials and processes.

- Utilizing 3D printing technology to create custom screws and bolts reduces the need for costly tooling and machining.

- Reusing existing parts can also minimize waste.

- In the manufacturing phase:

- Producing custom screws and bolts in small batches helps to conserve resources and reduce costs.

- Automation can help to improve production efficiency and reduce waste.

Enhances Productivity

Using custom screws and bolts can significantly enhance productivity in manufacturing operations. It not only increases cost efficiency through uniformity, but also ensures safety standards are met and environmental impacts reduced. Custom screws and bolts are designed to meet the specific requirements of each particular application, ensuring proper fit and reliable performance. This reduces the amount of time and resources spent on assembly and rework. Quality custom screws and bolts also offer high-temperature resistance and long service life, making them a more cost-effective option than using multiple parts. By leveraging the benefits of custom screws and bolts, manufacturers can boost productivity while maintaining safety and environmental standards. Transitioning to the next section, let us examine the long service life of custom screws and bolts.

Long Service Life

Custom screws and bolts offer a long service life, making them a cost-effective and reliable solution for manufacturing operations. Benefits include:

- Environmental Impact:

- Corrosion resistance, reducing the need for treatments and coatings.

- Low weight, reducing energy consumption during transportation and assembly.

- Corrosion Resistance:

- Durability in extreme conditions, reducing the need for frequent replacements.

- Minimizing costly repairs and downtime.

- Cost Effectiveness:

- Low maintenance, with less money spent on repairs and replacements.

- High return on investment, with a long service life and low initial cost.

Custom screws and bolts provide a cost-effective solution for manufacturing operations. Their long service life and corrosion resistance make them an ideal choice for manufacturers looking for a reliable and sustainable option.

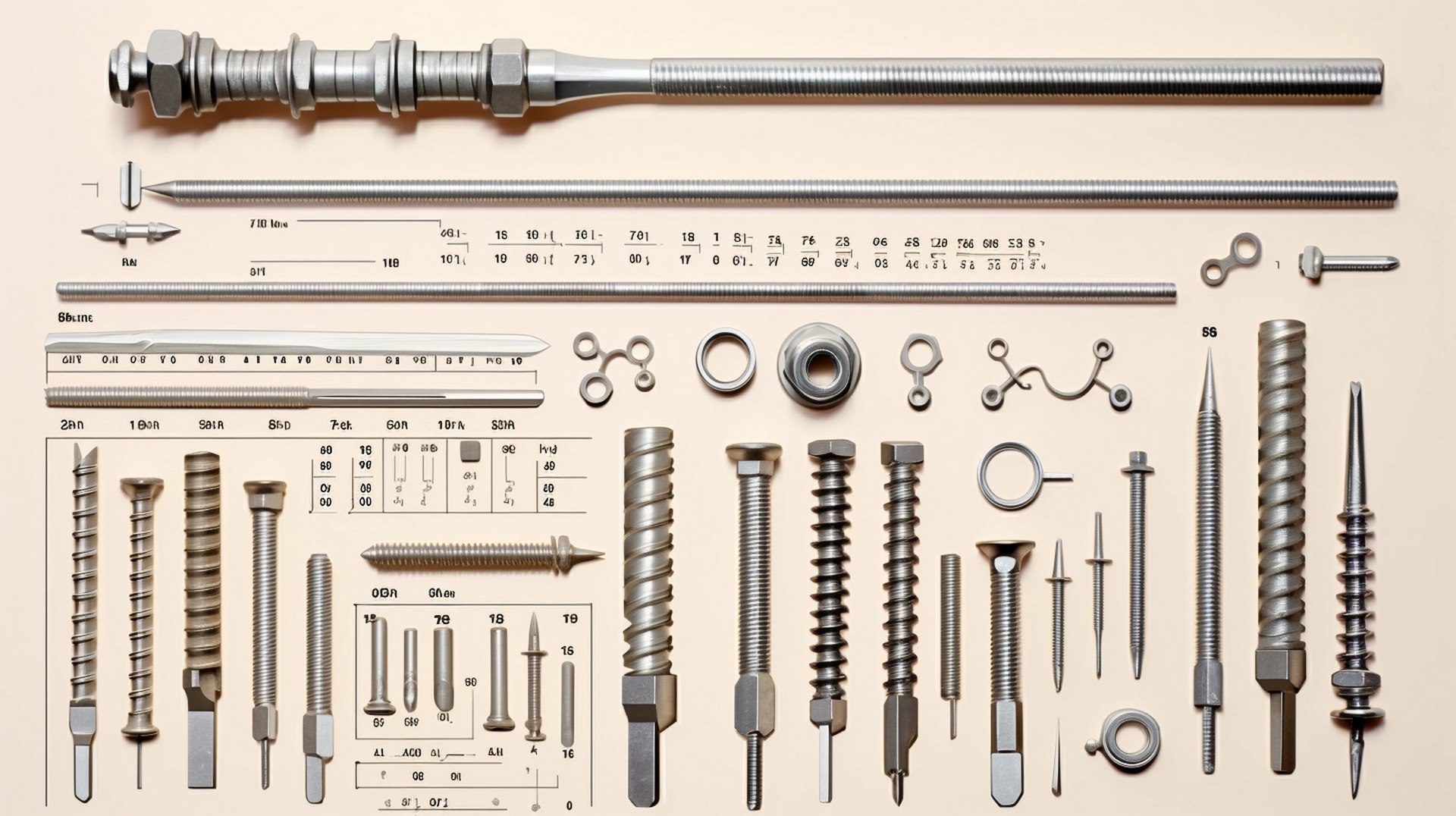

2. Types of Custom Screws Options

When it comes to custom screws, there are many different options to choose from, including lag screws, self-drilling screws, machine screws, sheet metal screws, and hex cap screws. Each has its own unique characteristics and advantages, making it possible to find the ideal screw for any application.

Lag screws

Many types of custom lag screws are available to meet a variety of needs. These include:

- Wire gauges: From fine-thread to coarse-thread, a wide range of wire gauges is available to match the strength and size requirements of the job.

- Thread types: Threads are available in both left-handed and right-handed options, and in a range of sizes, lengths, and pitches.

- Corrosion resistance: Several materials are available for use in lag screws, each with its own level of corrosion resistance.

Custom lag screws have a longer thread length than standard screws, which helps them better secure into soft materials such as wood. This makes them ideal for applications that require a strong hold. Additionally, they often come with a hex head or square head for a secure fit, and they are available in a variety of sizes to accommodate different projects.

Self-drilling screws

A wide variety of self-drilling screws are available to meet the needs of any project. These specialized screws are designed to drill into materials such as sheet metal, plastic and wood without the need for pre-drilling a pilot hole. Self-drilling screws can be used in applications such as securing roofing and siding or attaching metal components in industrial settings. They are also used in the construction of furniture, vehicles and other products.

When using self-drilling screws, it is important to consider the material being drilled into and the length of the screw. Using a screw that is too long could cause damage to the material, while a screw that is too short may not provide adequate fastening. It is also important to consider the environmental impact of the project, as self-drilling screws can produce noise, air and water pollution.

To ensure the best results, it is important to follow manufacturer's instructions for installation and use the proper tools for the job. In addition, users should wear protective gear such as goggles, gloves and respirators. By following these tips, users can ensure that their project is completed safely and efficiently, while minimizing environmental impact.

Machine screws

Machine screws are one of the most common types of custom screws available, designed for fastening metal parts together. Threading techniques, design considerations, and lock nuts are all important components of this type of screw:

- Threading techniques: thread size and pitch, material, and coating.

- Design considerations: head type, shank length, and thread length.

- Lock nuts: used to secure the screw in place and provide extra stability.

Sheet metal screws

How suitable are sheet metal screws for custom screw applications? Sheet metal screws are versatile and durable fasteners that offer corrosion protection for a wide range of applications. These screws are available in various thread types, including coarse thread, fine thread, and thread cutting. Additionally, sheet metal screws are easy to install, as they are designed to be driven directly into pre-drilled holes without the need for additional tools.

| Feature | Benefit |

|---|---|

| Corrosion protection | Prevents fasteners from rusting or corroding in harsh environments |

| Thread types | Variety of thread types available for different applications |

| Installation techniques | Easy to install without using additional tools |

For custom screw applications, sheet metal screws are a great option due to their superior corrosion protection, array of thread types, and simple installation process. Thanks to their versatile design, sheet metal screws can be used in a number of different projects.

Hex cap screws

Building on the versatility of sheet metal screws, hex cap screws are another popular option for custom screw applications. They offer a range of threading methods, making them suitable for a range of applications. Additionally, hex cap screws offer superior corrosion resistance and thread locking properties when compared to other types of screws.

Hex cap screws come in a variety of thread types, including UNC, UNF, and metric. Each thread type has a different purpose, allowing you to customize your screw to your needs. When it comes to threading methods, hex cap screws are available in a variety of styles, such as rolled, cut, or tap.

For greater corrosion resistance and thread locking, hex cap screws are made of stainless steel, brass, or other corrosion-resistant materials. This makes them ideal for applications that require strength and durability. Additionally, they can be treated with special coatings to further improve their resistance to corrosion.

Socket set screws

Of the many custom screw options available, socket set screws are a popular choice due to their versatile and strong threaded design. Quality assurance is a top priority, as these screws are designed to hold materials securely in place. The corrosion resistance of socket set screws further adds to their durability and reliability. They are used in a wide range of applications, including furniture, machinery, and more. Socket set screws are available in different sizes and shapes, allowing users to customize their projects to suit their needs. Additionally, these screws are easy to install, making them ideal for quick fixes or long-term applications. Socket set screws are an excellent choice for projects that require a strong and secure solution.

Socket cap screws

Socket cap screws are a popular type of custom screw option due to their high strength and versatility. They are available in various sizes and lengths, and the head of the screw is typically larger than other types of screws. Socket cap screws can be used with a variety of drilling techniques and thread types, and are suitable for a wide range of fastening strength requirements.

- Drilling Techniques:

- Holes for socket cap screws can be drilled with a standard drill bit, a countersink drill bit, or a counterboring drill bit.

- Thread Types:

- Socket cap screws can be found with either an internal or external thread type.

- Fastening Strength:

- The fastening strength of socket cap screws varies depending on the material the screw is made of, the length, and the thread type.

Button socket cap screws

Versatility and strength make button socket cap screws an ideal custom screw option for a variety of applications. These screws come with either coarse or fine threads and taps, and their strength and design make them effective for a wide range of applications. Button socket cap screws are made from strong materials that are resistant to corrosion and rusting, making them an excellent choice for outdoor projects. Their design also provides an aesthetically pleasing finish to any project. Additionally, these screws are easy to install, making them a popular choice for many. They are also more affordable than other custom screws. Thanks to their versatility, strength, and affordability, button socket cap screws are a great choice for many custom screw projects. These screws provide both function and design, making them a great option for any custom project. The next topic to discuss is 'flat head socket cap screws'.

Flat head socket cap screws

Another popular type of custom screw is a flat head socket cap screw, which provides a unique look and increased strength compared to other screw types. It is ideal for fastener installation and features high-quality threading techniques and corrosion protection.

These screws can be custom-made to meet the customer's needs. They come in a variety of shapes, sizes, and materials to meet any job requirement. Customization options include:

- Threading techniques: Choose between metric or imperial threads for precise fastening.

- Corrosion protection: Enhance the durability and lifespan of the fastener with a coating, such as zinc or stainless steel.

- Fastener installation: Select a fastener that is easy to install and provides a secure fit.

Flat head socket cap screws provide an effective and reliable way to secure objects in place. With the right customization options and threading techniques, they are ideal for a variety of applications.

Shoulder socket screws

For applications requiring a more versatile fastener, shoulder socket screws are a great option. This type of screw is designed with a shoulder that fits into a countersunk hole, allowing for adjustment after installation. Threading techniques can vary based on the application, with options such as rolled threads, cut threads, or buttress threads. When buying shoulder socket screws, it is important to consider the diameter, thread pitch, length, and material grade. Quality control is also an important consideration, as this will ensure the screws match the desired specifications. To ensure the best performance, it is recommended to use high-quality screws that have been tested and certified for accuracy and reliability.

Concrete screws

When it comes to custom screws and bolts, one of the most popular options is concrete screws. Choosing the right material, screw size, and thread type are all essential in ensuring a secure and reliable fit.

- Choosing Materials:

- Steel: Most common material used for concrete screws.

- Stainless Steel: Offers greater corrosion resistance.

- Zinc-Plated Steel: Best for outdoor applications due to its weatherproof finish.

- Screw Size:

- Length: Longer screws should be used in heavier materials.

- Diameter: Larger screws are more secure, but too large can damage the material.

- Thread Types:

- Phillips: Most common thread type used.

- Hex: High-strength thread that is difficult to strip.

- Square: Offers greater torque and is more resistant to wear.

Deck screws

Building on the importance of choosing the right materials, screw size, and thread type for concrete screws, deck screws are another type of custom screw that require careful consideration. Deck design, strength, and maintenance all depend heavily on the quality of these screws. Properly selected deck screws must be corrosion-resistant, strong enough to hold the decking boards in place, and designed to be driven with minimal effort.

| Material | Corrosion Resistance | Strength |

|---|---|---|

| Stainless Steel | High | High |

| Galvanized Steel | Medium | High |

| Silicon Bronze | High | Low |

| Aluminium | Low | Low |

When considering deck screws, it's important to select the right material, size, and thread type. Each of these have a significant impact on the quality of the deck and its longevity. With careful selection, the right deck screws can ensure the deck remains strong and structurally sound for years.

Self-tapping screws

Self-tapping screws are a type of custom screw that are designed to cut their own threads as they are driven into a material. Without self-tapping screws, it would be difficult to affix two pieces of material together.

The main benefit of self-tapping screws is that they can be easily used without the need for additional tools or machinery. They also come in a variety of sizes and shapes, making them suitable for a variety of applications.

When it comes to customizing self-tapping screws, there are several considerations to be made:

- Friction Coating: This is a process that helps to reduce friction between the screw and the material it is being driven into.

- Thread Design: Different thread designs are available to increase the gripping power of the screw.

- Hardening Processes: Different hardening processes can be used to increase the strength and durability of the screws.

Sems screws

Another option for custom screws are sems screws, which are a type of screw with a pre-assembled washer or nut. Sems screws provide greater stability as the washer and nut help to reduce the risk of the screw becoming loose. Sems screws are also advantageous as they require fewer steps in the assembly process. This type of screw offers versatility as it can be used with various materials, including stainless steel, due to the material's durability and corrosion-resistant properties. Additionally, sems screws have threads on both the body and the head, which provides better holding power than self-tapping screws as the threads are more prominent. Furthermore, sems screws have self-threading advantages and are often used in applications where threads vs taps need to be considered. Ultimately, sems screws are a great option for custom screws and provide a secure, reliable solution.

| Properties | Sems Screws | Self-tapping Screws |

|---|---|---|

| Washer/Nut | Pre-assembled | N/A |

| Versatility | Can use various materials | Limited materials |

| Threads | On body & head | On body only |

| Holding Power | Higher | Lower |

| Self-threading | Yes | No |

Thumb screws

Offering a secure, low-torque solution, thumb screws are an ideal option for custom screws. With their distinct design, thumb screws offer great versatility and can be used in a variety of applications.

When designing thumb screws, there are a few key features to consider, such as:

- Screw Threading: The threading of the screw is essential in order to ensure it fits properly into the desired object. Custom threading is available to provide a precise fit for specific applications.

- Head Shape: The head of the thumb screw is designed to provide a secure grip when the screw is tightened or loosened.

- Material: The material of the thumb screw is also an important consideration, as it affects the strength and durability of the screw.

3. A Conclusion Specifications Table of Custom Screws

In order to make an informed decision when choosing custom screws, it is important to be aware of the different head styles, industries and applications, finishes, and industry standards available. To provide an overview of these options, a conclusion specifications table is the ideal way to compare the different types of custom screws.

| Specification | Options |

|---|---|

| Screw Head Styles | |

| Thread Count | Coarse Threads, Fine Threads, Extra Fine Threads |

| Drive Types | Slotted, Phillips, Square Drive, Torx |

| Torque Settings | Low Torque, High Torque, Self-Locking Torque |

| Industries & Applications | |

| Body Composition | Tailored to match application's material requirements |

| Thread Design | Tailored to fit application's needs |

| Coating Selection | Based on the environment of intended use |

| Finishes | |

| Coatings | Zinc-plated, Galvanized, Nickel-plated, Anodized |

| Thread Types | Machine screws, Threaded rods, Bolts, Nuts |

| Fastening Efficiency | Shear strength, Tension, Torque |

| Industry Standards | |

| Thread Standards | Size, Depth, Pitch |

| Quality Control | Ensures screws are free of defects |

| Safety Regulations | Compliance with industry safety standards |

| Testing | All screws tested to meet industry regulations |

Knowing the right combination of coatings, thread types, and fastening efficiency for custom screws and bolts allows for better control and precision of the desired outcome in various applications.

4. What You Should Search for in a Custom Screw?

When searching for a custom screw, there are certain characteristics that must be considered:

- Sourcing Tips:

- Research the screw maker's reputation and experience.

- Examine the manufacturer's certifications and quality control standards.

- Check the availability of parts and customer service.

- Thread Options:

- Choose a thread type that is compatible with the application.

- Consider the thread size and pitch when selecting a screw.

- Check if a mechanical or chemical threadlocker is required.

- Sizing Guidelines:

- Measure the length of the screw to ensure proper fit.

- Study the head type and size of the screw.

- Check the shape and size of the drive to ensure compatibility.

When selecting a custom screw, it is important to pay attention to these details. Doing so will ensure that the screw meets the application's standards and provides long-term quality and performance. It is also important to ensure that the parts are sourced from a reliable manufacturer, as this ensures that the product is of the highest quality and can withstand the rigors of the application.

5. Types of Custom Bolts:

Custom bolts come in a variety of shapes and sizes, each with unique characteristics and applications. Socket shoulder bolts, flange bolts, 12 point flange bolts, carriage bolts, and plow bolts are just some of the many types of custom bolts available. Each type has its own unique features and benefits that make it ideal for a variety of projects.

Socket Shoulder Bolts

Designing and manufacturing custom socket shoulder bolts is a great way to meet specific needs. Socket shoulder bolts are threaded connections that are used in many industries, from automotive to aerospace. They are known for their strength and dependability, making them the perfect choice for applications that require high mechanical strength.

The thread design of socket shoulder bolts is of utmost importance, as it affects the performance of the part. The thread design must be precise to ensure a secure fitting, and must be made to the customer's exact specifications. Additionally, the strength of the material used for the bolt will have an effect on the strength of the joint.

Socket shoulder bolts are also known for their precision and versatility. They are available in a variety of sizes, materials, and finishes, allowing for a wide range of applications. With the right design and materials, socket shoulder bolts can provide a secure and reliable connection that will stand the test of time.

Flange Bolts

Moreover, flange bolts are another type of custom bolts commonly used in a variety of applications. These bolts are characterized by a built-in washer-like flange that distributes the load over a greater area, making them ideal for applications that require extra strength and stability. The flange also helps to protect the surface of the material from being damaged, as well as providing additional corrosion protection. Flange bolts can be used in a range of applications including electrical equipment, engines, machinery, and furniture.

The thread dimensions of flange bolts are typically larger than other custom bolts, however the flange helps to ensure that the bolt is properly secured for increased reliability. The flange also helps to prevent movement and vibration, which is especially helpful in applications requiring a high degree of precision. Flange bolts are made from a variety of materials including stainless steel, brass, and aluminum, all of which offer superior strength and durability.

12 Point Flange Bolts

Fabricating point flange bolts can provide extra protection and stability to a variety of applications. Point flange bolts have many strengths that make them an ideal choice for custom bolts:

- Point Flange Strengths:

- They are designed to be easily accessible and provide a secure fit

- They are corrosion-resistant and offer superior strength and durability

- They provide a larger surface area for better grip

- Flange Application:

- Used in applications such as machinery, construction, and automotive

- Can be used in both interior and exterior applications

- Can be used for both structural and non-structural applications

- Flange Grades:

- Depending on the application, there are various grades of point flange bolts

- Grade 8 and Grade 9 are the most common grades used in custom applications

- Grade 10 is the highest grade and is the most expensive but provides the most secure fit.

Point flange bolts offer a combination of strength, security, and durability, making them an ideal choice for custom applications.

Carriage Bolts

Carriage bolts are custom screws and bolts that are commonly used in a variety of applications. They feature a square neck under the head and a threading technique that is designed to secure the bolt into the material it is used with. Manufacturing carriage bolts requires specialized heat treating and corrosion protection to ensure that they are strong and durable. This makes them the ideal choice for use in outdoor applications and in areas where they may be exposed to moisture and other elements. The square neck makes them easy to install and remove, and the corrosion protection ensures that they remain strong and secure for years to come. In addition, they are also cost effective and easy to find. With the right threading technique and heat treating, carriage bolts can provide reliable and secure fastening for many applications.

Plow Bolts

We offer a variety of plow bolts, which are types of custom screws and bolts commonly used in applications that require a strong and secure fastening. Our plow bolts come in a range of sizes, thread types, and finishes, allowing for customizing fasteners to meet any need. Additionally, our plow bolts are offered with different levels of corrosion protection, providing our customers with the confidence that their fasteners will remain reliable and secure.

For any application requiring a strong and secure fastening, plow bolts are a great option. Our selection of plow bolts provides our customers with the assurance that they are getting a quality custom fastener. From here, we will discuss the types of custom bolts known as hex tap bolts.

Hex Tap Bolts

What types of custom bolts are available for fabricating projects? Hex tap bolts are a popular option for many applications. Fabricators have a range of options when it comes to alloys, thread types, and surface treatments. Alloy selection is important for determining the strength, corrosion resistance, and other properties of the bolt. Thread types can be customized to meet specific requirements, while surface treatments offer additional protection from the elements and wear. Hex tap bolts offer a variety of customization options for fabricators, making them ideal for a range of projects.

Structural Bolts

Many fabricators choose structural bolts for their custom projects, as they are designed with specific strength requirements in mind. Structural bolts offer a variety of design considerations for custom projects, including:

- Bolt Strength: Structural bolts are designed to have a specific tensile strength and shear strength to ensure they can handle the weight and stress of the application.

- Corrosion Resistance: Structural bolts are treated with a protective coating that helps to keep them from corroding, which is important for any custom project that may be exposed to the elements.

- Design Considerations: Structural bolts come in a variety of sizes and shapes, so they can be used to fit any custom project. They can also be customized with a variety of finishes and coatings to ensure they match the aesthetic of the project.

Elevator Bolts

Elevator bolts are a type of custom bolt used to secure heavier loads in place. The design of elevator bolts features a threaded shank with a flat head and a short square neck. This design allows for the bolt to be secured in place without a nut, making it ideal for applications that require a high degree of strength and stability. The surface finish of elevator bolts also varies depending on the application, allowing for increased corrosion resistance or a more aesthetically pleasing finish. In addition, elevator bolts have specific torque requirements that must be met for a successful installation. By taking into account the threaded design, surface finish, and torque requirements, elevator bolts can be custom tailored to fit the needs of any project.

Eye Bolts

Additionally, eye bolts are a type of custom bolt often used in applications that require a secure connection with a readily accessible point. Threading techniques, strength requirements, and torque specifications are essential considerations when customizing eye bolts.

- Threading Techniques:

- Different threading techniques can be applied to create eye bolts with the desired strength, flexibility, and form.

- Strength Requirements:

- The strength requirements of the eye bolt must be taken into consideration to ensure that it can withstand the desired load.

- Torque Specifications:

- The torque specifications are important for ensuring the eye bolt is properly secured and does not come loose over time.

At the end of the day, customizing eye bolts requires careful consideration of the threading techniques, strength requirements, and torque specifications to ensure that the bolts are strong and secure.

U-Bolts

U-bolts are a type of custom bolt characterized by their 'U' shape. They are often used for fastening objects such as poles, pipes, and conduit. U-bolts are available in a variety of threading methods, each with its own corresponding advantages and disadvantages. In terms of fastener strength, U-bolts provide superior resistance to shear and tension forces, making them ideal for heavy-duty applications. Additionally, they come with a variety of corrosion protection options, including galvanized, zinc plated, and stainless steel.

| Threading Method | Advantages | Disadvantages |

|---|---|---|

| Unified National Coarse | Low cost | Low strength |

| Unified National Fine | High strength | High cost |

| Metric Coarse | High strength | Low corrosion resistance |

| Metric Fine | High corrosion resistance | High cost |

| Whitworth | High accuracy | Low strength |

Heavy Hex Bolts

Heavy hex bolts are a type of custom bolt that is designed to withstand higher levels of tension and shear forces than standard bolts. They are often used in manufacturing and construction processes, and can be customized to fit specific needs:

- Customizing Processes: Pitches, diameters, and lengths of the bolts can be tailored and altered to suit the requirements of the job.

- Manufacturing Processes: Bolts can be made from a range of materials and treated with a variety of heat treatments to create a stronger and more durable product.

- Heat Treatments: Heating treatments such as annealing, stress-relieving, and quenching can be used to increase the strength of the bolts.

These heavy hex bolts are a great option for projects that require higher levels of tension and shear forces. The ability to customize them for specific needs makes them a great choice for many manufacturing and construction projects. With their superior strength and durability, they are a great choice for any application. The next section of this article will discuss the use of custom bolts in stadium seat installations.

Stadium Seat Bolts

Custom U-bolts are a type of custom bolt designed to provide superior strength and stability for stadium seat installations. They are widely used in most major sports arenas and stadiums, and offer a great solution for seat design and stadium construction. U-bolts are available in a variety of sizes, styles, and materials, and provide a secure connection between the seat and the mounting surface. When installing custom U-bolts, it is important to ensure the correct length and diameter for the application. It is also important to use the proper installation tools to ensure that the seat is properly secured. Additionally, it is important to follow any applicable safety guidelines to prevent any accidents or injuries. Following these installation tips will ensure that your stadium seating is safe and secure.

Hex Bolts

In addition to U-bolts, another type of custom bolts are hex bolts. Hex bolts are most commonly used for fastening two or more parts together and are available in a variety of threading types, specialty designs, and impact strengths.

- Threading Types

- Coarse Threads

- Fine Threads

- Left-hand Threads

- Specialty Designs

- Shoulder Bolts

- Carriage Bolts

- Elevator Bolts

- Impact Strengths

- Low Carbon Steel

- Grade 5 Steel

- Grade 8 Steel

Hex bolts are the most commonly used of all custom bolts, and provide an easy-to-use option for a wide variety of projects. With their durability and versatility, hex bolts are an ideal option for many construction and design projects. From here, we will move on to discuss large diameter bolts.

Large Diameter Bolts

When it comes to large diameter bolts, there are a variety of types available to suit any project needs. Depending on the application, you can choose from a range of threading options, material selection, and bolt installation. Threading options include metric, UNC, UNF, and other specialty thread forms. Material selection depends on the application requirements and can include stainless steel, carbon steel, aluminum, brass, and other alloy metals. Bolt installation is usually done with a wrench or a socket, although other tools may be needed depending on the size and type of bolt. To ensure the best possible outcome, it is important to select the right bolt with the right threading and material for the job. With the right selection, large diameter bolts can provide secure and reliable fastening. To make sure you get the right bolt for the job, it is recommended to consult with a custom bolt specialist who can offer professional advice and guidance. A conclusion specifications table of custom bolts should also be consulted to ensure the best outcome.

6. A Conclusion Specifications Table of Custom Bolts

The use of custom bolts in applications is often necessary in order to achieve the desired result. In order to understand the best choice for a specific application, it is important to consider the bolt head type, bolt grade, bolt material, and standard measurements. By understanding the range of available options, the most suitable custom bolt can be found for any task.

| Specification | Options |

|---|---|

| Applications of Custom Bolts | |

| Benefits | Cost Savings, Design Flexibility, Quality Assurance |

| Industrial Applications | Manufacturing, Engineering, Construction |

| Automotive Applications | Engines, Transmissions |

| Aerospace Applications | Aircraft, Spacecraft |

| Bolt Head Types | |

| Hex Bolt | Machine Threads, Zinc Plating, High Tensile Strength |

| Socket Bolt | Rolled Threads, Anodizing, High Shear Strength |

| Carriage Bolt | Cut Threads, Powder Coating, High Lateral Strength |

| Bolt Grades | |

| Grade A | Extreme Precision and Accuracy |

| Bolt Material Options | |

| Steel | Economical Option |

| Stainless Steel | Increased Corrosion Protection |

| Brass | Common Material |

| Titanium | Strongest and Lightest Option |

| Galvanized/Zinc Plated Steel | Extra Corrosion Protection |

| Bolt Size Standards & Measurements | |

| Threading Standards | Metric and Inch Threads, Right and Left-Hand Threads, Thread Forms |

| Hardening Processes | Heat Treating, Tempering, Carburizing |

| Fastening Methods | Bolting, Welding, Riveting |

Accurately measuring bolt size is essential for the success of any project. With the right specifications, custom bolts can be created to withstand any job. Understanding and using the right standards and measurements is key to achieve the desired results.

7. Company Summaries of Top Featured Fastener Manufacturers and Suppliers

Nine of the top featured fastener manufacturers and suppliers have been compiled to provide an overview of their services and products. Below is a summary of the companies and what they offer:

| Company | Services | Products |

|---|---|---|

| Nine Fasteners, Inc. | Distributor | Various fasteners |

| Fast-Rite International, Inc. | Standard & custom fasteners | Logistics services |

| Chicago Nut & Bolt, Inc. | Fasteners to various industries | N/A |

| Big Bolt | Fasteners & additional services | Slotting & milling |

| EPS | Custom fasteners | Cold-formed parts |

| Armour Screw Co. | Distributor | Nuts, rivets, washers |

| Associated Fastening Products, Inc. | Fasteners to automotive & transportation industries | N/A |

| National Bolt & Nut Corp. | Custom manufacturing | Wide range of fasteners |

| Hi-Tech Fasteners, Inc. | Distributor | Fasteners & related products |

| PennEngineering | Wide range of fasteners | Over 1000 employees |

Custom screws and bolts offer advantages such as improved strength and durability, flexibility in design, and cost savings. There are various types of custom bolts and screws available, such as hex bolts, lag screws, carriage bolts, and cap screws. Custom screws and bolts are used in a wide range of applications, including construction, automotive, and electronics.

8. FAQs of Custom Screws and Bolts

Custom screws and bolts are essential components of many industrial and domestic projects, and there are many questions surrounding their design, making, and strength. This article will look to answer some of the most commonly asked questions about custom screws and bolts, such as whether they can be made, who makes them, and which is stronger - bolts or set screws.

Can You Get Custom Screws Made?

Have you ever wondered if it is possible to get custom screws made? Absolutely, it can be done through several different methods.

- Custom Parts Design: Companies can design custom screws and bolts to meet the unique specifications and dimensions needed for a project or product.

- Quality Assurance: Quality assurance is ensured through the use of advanced software and 3D printing technology that allows for precise measurements and quality control.

- Cost Efficiency: Despite the custom nature of these screws, they are still cost-efficient as they are designed for mass production.

Custom screws and bolts are a great way to get the exact product you need for your project or product. The process is reliable and cost-efficient, while also allowing for precise measurements and quality assurance.

Can You Get Bolts Made?

How easily can bolts be custom-made? With the right resources, custom bolts can be made to exact specifications with a variety of shapes, sizes, and lengths. The screw length, screw threads, and bolt designs can all be made to meet the needs of the customer's project. Depending on the size and complexity of the project, the bolts may need to be made from specialty materials like stainless steel or aluminum. The manufacturer should be able to provide a variety of screw lengths, thread types, and bolt designs to fit any project. With the right resources, custom bolts can be made quickly and efficiently. This allows customers to have greater control over the design and specification of their project. Understanding who makes screws and bolts is the next step in the process.

Who Makes Screws and Bolts?

When it comes to custom screws and bolts, many customers have questions about who manufactures them and what the process looks like. Choosing a reliable supplier is key to obtaining the quality and accuracy required for a successful outcome.

- Choosing Suppliers: Spend time researching potential suppliers, looking into their background, capabilities, and certifications. Ensure they have the right equipment to provide the desired thread forms.

- Screw Threads: Many types of thread forms are available, including UNC, Acme, and Metric threads. Choose the correct thread for the application, taking into consideration factors such as size, material, and strength.

- Buying Guidelines: Consider the material and strength of the bolts, as well as the environment in which they will be used. Also, consider the type of plating and coating that will be required.

Are Bolts Stronger Than Set Screws?

Continuing from our discussion of who makes screws and bolts, one common question is whether bolts are stronger than set screws. The answer depends on the type of fastener being compared. Bolts, which are tightened by turning a nut, are usually stronger than set screws, which are tightened by turning the head of the fastener. The strength of a bolt also depends on the type of material used and the thread type, as well as the metric measurements and softening points. Bolts in general tend to be stronger than set screws, but always refer to the manufacturer's specifications for exact strength data. The size and diameter of the fastener, the length of the thread, and the type of material used can all affect the strength and durability of the bolt.

Mikehardware-your trusted custom screws and bolts manufacturer

Custom screws and bolts offer a variety of advantages and benefits for industrial applications. With a wide range of options available, customers can choose the right product for their needs. Specifications tables give an overview of custom screws and bolts, while top fastener manufacturers and suppliers provide quality assurance and customer service. Juxtaposing the various types of custom screws and bolts, customers can find the perfect product for their application needs. Quality, cost, and performance are the key elements to consider when selecting custom screws and bolts.

Dongguan Mike Hardware Co., Ltd. leverages 20 years of industry expertise, boasting a skilled team and cutting-edge facilities. Specializing in CNC product manufacturing, we offer a wide array of fastener solutions—from special coating to standard screws. Trust us for precision-engineered custom screws and bolts, ensuring top-notch quality.

Contact us for a free quote of your ideal custom screws and bolts!