Custom Screw Manufacturing

Custom screw manufacturing is a crucial aspect of various industries, providing tailored solutions for specific needs. From custom OEM screws to machined screws, the options are vast and can be overwhelming at first glance.

In this discussion, we will explore the intricacies of the custom screw manufacturing process, shedding light on the factors that contribute to its success. Additionally, we will uncover which country holds the crown for manufacturing the most screws, as well as provide a comprehensive guide to help you navigate through the plethora of custom screw options available.

So, let's embark on this journey together and uncover the fascinating world of custom screws.

Key Takeaways

- Custom screw manufacturing offers specialized screws for specific requirements in industries such as aerospace, automotive, electronics, and medical devices.

- Advantages of custom screws include improved functionality, efficiency, and durability.

- Raw material selection, manufacturing processes such as drive cutting and thread rolling, heat treatment, and coating are crucial for the quality and performance of custom screws.

- Custom screws meet specific requirements in different industries, contribute to efficiency, precision, and durability, and are expected to see increased demand in the future.

1. Introduction to Custom Screw & Custom OEM Screw & Machined Screw

This section provides an introduction to the different types of custom screws.

We will explore what custom screws are, as well as the concept of custom OEM screws and machined screws.

Additionally, we will discuss the benefits that custom screws offer in various manufacturing settings.

1.1 What is Custom Screw?

Custom screw manufacturing refers to the process of creating specialized screws tailored to specific requirements, including custom OEM screws and machined screws. These custom screws find applications in various industries, such as aerospace, automotive, electronics, and medical devices.

The advantages of custom screws are plentiful, including improved functionality, increased efficiency, and enhanced durability. The custom screw manufacturing process involves several steps, such as design, material selection, machining, and finishing.

There are different types of custom screws available, such as socket head cap screws, machine screws, self-tapping screws, and shoulder screws, each designed to serve specific purposes.

1.2 What is Custom OEM Screw?

The concept of custom OEM screws, as part of the custom screw manufacturing process, involves the creation of specialized screws tailored to meet specific requirements in various industries.

Custom OEM screws offer numerous advantages in terms of their applications and the customization options available. These screws are designed to fit specific applications, ensuring optimal performance and reliability. The customization options for screws include variations in size, shape, material, and thread type, among others. This allows for a precise fit and enhanced functionality in different settings.

The importance of custom screw manufacturing lies in its ability to provide solutions that standard screws cannot fulfill. By offering tailored solutions, custom OEM screws contribute to improved efficiency, increased productivity, and overall cost savings for industries that require specialized fasteners.

1.3 What is a Machined Screw?

Machined screws are a type of specialized fasteners that are precision-engineered to meet specific requirements in various industries. These screws are manufactured using a precise machining process, which ensures their accuracy and reliability.

There are several types of machined screws available, including:

- Precision screws: These screws are designed to provide high levels of accuracy and control in applications that require fine adjustments.

- Threaded screws: These screws have threads that allow them to be easily screwed into a pre-drilled hole, making them ideal for fastening applications.

- Customized screws: These screws are tailor-made to meet specific requirements, such as size, shape, and material composition.

The advantages of machined screws include their high strength, durability, and corrosion resistance. They find applications in industries such as aerospace, automotive, electronics, and medical equipment manufacturing.

The manufacturing process for machined screws involves CNC machining, which ensures precise dimensions and tight tolerances.

1.4 The Benefits of Custom Screws

Custom screws offer a range of advantages that contribute to the efficiency, precision, and durability of various industrial applications. One of the key benefits of custom screws is their ability to meet specific requirements and address unique challenges in different industries.

The customization options available allow for the design and production of screws that perfectly fit the desired specifications, resulting in improved performance and reliability. Custom screws find applications in electronics manufacturing, where they enable the assembly of small parts and maintain the architecture of electronic devices. They also facilitate easy repair and replacement, reducing downtime and increasing productivity.

In addition, custom screws help in reducing waste in manufacturing processes by enabling precise ordering and minimizing wastage. As industry trends continue to evolve, the demand for custom screws is expected to rise, highlighting their importance in various sectors.

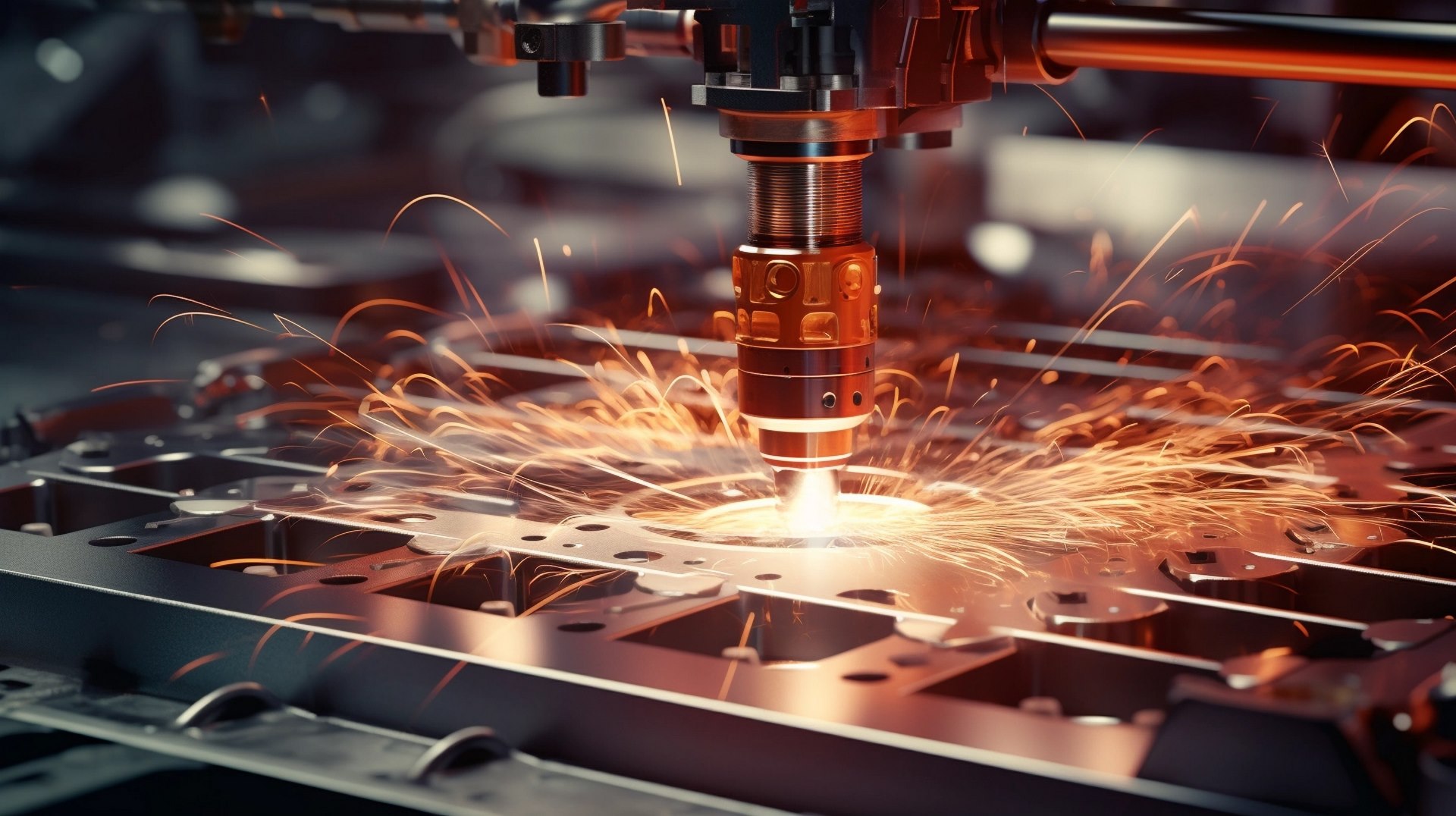

2. The Process of Custom Screw Manufacturing

The process of custom screw manufacturing involves understanding the history of how screws are made and how they are made today.

By exploring the evolution of screw manufacturing techniques, we can gain insights into the advancements and innovations that have shaped the industry.

This discussion will delve into the historical background and current practices of custom screw manufacturing.

2.1 History of How Are Screws Made

Throughout history, the process of manufacturing screws has evolved and undergone significant advancements. Some key points to consider regarding the history of how screws are made include:

- Ancient Egyptians and Babylonians used screw-threaded rods as a pump to pull water for irrigation purposes.

- The philosopher Archimedes introduced the concept of the screw in ancient Greece.

- Evolution of screw designs:

- The modern screw as we know it appeared during the 1500s in Germany, initially handcrafted from compressed head nails.

- Early screws were handmade and varied in design, limiting their industrial use.

- Impact of screw manufacturing on industrialization:

- Mass production of screws became possible with the development of machines in the late 18th century, such as screw-cutting lathes.

- Lower manufacturing costs led to increased usage and further improvements in screw manufacturing technology.

- Future of screw manufacturing technology:

- The technology behind making screws has continually improved, reaching its current state in the 1980s.

- The future of screw manufacturing technology holds the potential for even more advancements in efficiency and precision.

2.2 How Are Screws Made Today?

The process of custom screw manufacturing involves various steps.

One important step is fastener design, which determines the specific features and standards of the screw.

Another step is raw material selection. This involves choosing the appropriate materials, such as metal wire or bar stock, to create the screw blanks.

Drive-cutting and thread-rolling methods are employed to shape the head and thread of the screw.

Additionally, thread cutting is an alternative technique used for lower-volume custom screw production.

Fastener Design

Fastener design plays a crucial role in the modern manufacturing process of custom screws. It involves careful consideration of various factors to ensure the screws are tailored to specific requirements.

The advantages of custom screws in fastener manufacturing include enhanced functionality, improved durability, and increased efficiency.

The screw customization process involves precise measurements, material selection, and design optimization. By customizing screws, manufacturers can meet the unique needs of their applications, resulting in better performance and control.

Raw Materials

In the process of custom screw manufacturing, one crucial aspect to consider after fastener design is the selection of raw materials.

The choice of raw materials is vital as it directly impacts the quality and performance of the screws. Manufacturers must carefully analyze the manufacturing process, conduct thorough quality assurance checks, and perform cost analysis to ensure the selection of the most suitable raw materials.

Additionally, keeping an eye on industry trends helps in adopting innovative materials that enhance screw performance and durability.

Drive Cutting

Drive cutting is a crucial step in the manufacturing process of custom screws. It ensures the precise formation of the drive recess for optimal fastening performance. Drive cutting techniques involve creating various drive shapes, such as Phillips, Torx, or hex, using specialized cutting tools.

This process offers several advantages. First, it enhances torque transfer, allowing for better tightening and loosening of screws. Second, it reduces the risk of cam-out, which occurs when the driver slips out of the drive recess, preventing proper tightening. Lastly, drive cutting improves resistance to stripping, ensuring that screws remain securely fastened even under high loads or vibrations.

Drive-cutting finds applications in various industries, including automotive, aerospace, and construction. In these industries, secure and reliable fastening is essential for the safety and performance of products.

Thread Rolling

Thread rolling is a critical step in the modern manufacturing process of custom screws, ensuring the creation of high-quality threads for optimal fastening performance.

The thread rolling process offers several advantages over thread cutting, such as increased strength, improved surface finish, and reduced material waste.

This technique involves rolling a hardened die against the surface of a rotating screw blank, displacing the material to form the thread.

Thread rolling finds applications in various industries, including automotive, aerospace, and construction.

Related Article: Thread Rolling Process of Screws: The Basics

Thread Cutting

The process of custom screw manufacturing involves the technique of thread cutting, which plays a vital role in creating screws with precise threads for various industrial applications.

The thread-cutting process can be done using different methods, including single-point threading, tap threading, and die threading.

Advantages of thread cutting include the ability to create custom thread sizes and pitches, as well as the production of strong and durable threads.

Thread-cutting tools commonly used include taps, dies, and single-point cutting tools.

Related Article: Rolled Screw Threads VS Cut Screw Threads

Heat Treatment

One crucial step in the process of custom screw manufacturing is heat treatment, which plays a significant role in enhancing the strength and durability of screws for various industrial applications.

Heat treatment involves subjecting the screws to high temperatures in a vacuum furnace to achieve desired hardness and resilience. The screws are then rapidly cooled through a quenching process to further strengthen them.

Afterward, hardness testing is conducted to ensure the screws meet the required specifications.

Lastly, the screws undergo a tempering process to improve their toughness and reduce brittleness.

Coating

To enhance the performance and longevity of custom screws, an important step in the manufacturing process is the application of a specialized coating. The benefits of coating include improved corrosion resistance, reduced friction, and enhanced aesthetics.

There are various types of coatings available, such as zinc plating, nickel plating, and ceramic coatings. The application methods for these coatings include electroplating, hot-dip coating, and physical vapor deposition.

Choosing the right coating option and application method is crucial to ensure the desired performance and durability of custom screws.

Quality Control

Implementing a comprehensive quality control system is imperative in the process of custom screw manufacturing to ensure precision and reliability. Inspection techniques, defect prevention, and product testing are key components of quality control.

3. Which Country Manufactures the Most Screws?

Germany, China, the United States, Japan, and Italy are the leading countries in the manufacturing of screws. The screw manufacturing industry is continuously evolving, with various trends shaping the global screw market. Analysis of the market reveals that these countries have established themselves as key players in screw manufacturing, contributing significantly to the global supply.

Key trends in screw manufacturing include the emergence of new players in the market and the impact of automation on production processes. While Germany has long been known for its high-quality screws and precision engineering, China has rapidly emerged as a major player due to its cost-effectiveness and large-scale production capabilities. The United States, Japan, and Italy also play vital roles in the global screw market, with their expertise in specialized screw types and innovative production techniques.

Automation has revolutionized the screw manufacturing industry, enhancing efficiency and precision. With the implementation of automated systems, manufacturers can produce screws faster and with greater accuracy, resulting in improved product quality. This has allowed the leading countries to maintain their competitive edge in the market and meet the growing demands of industries worldwide.

As the global demand for screws continues to rise, these leading countries will continue to dominate the manufacturing landscape. Their expertise, technological advancements, and commitment to quality control position them as leaders in the production of screws, ensuring a steady supply for industries that desire control over their fastening solutions.

4. Guide to Custom Screw Options

When it comes to custom screw options, there are several key points to consider.

Firstly, the choice of materials plays a crucial role in determining the strength and durability of the screws.

Secondly, the size of the screws needs to be carefully selected to ensure proper fit and functionality in the desired application.

Lastly, factors such as standard specifications, finishing options, and head types offer additional customization possibilities to meet specific requirements.

4.1 Materials

A wide range of materials are available for custom screw manufacturing, including carbon steel, stainless steel, alloy, copper/brass, titanium, aluminum, Monel, Inconel, and Hastelloy. The choice of material is crucial in determining the performance and durability of the custom screws.

Material selection depends on factors such as the application requirements, environmental conditions, and manufacturing processes. Customization options are available to meet specific needs, allowing for variations in material composition, hardness, corrosion resistance, and other properties.

Quality assurance is an essential aspect of custom screw manufacturing, ensuring that the materials used meet industry standards and customer specifications. Manufacturers employ rigorous testing and inspection procedures to guarantee the reliability and performance of the custom screws.

4.2 Size

The size of custom screws can vary greatly, with diameters ranging from M1 to M100 and lengths ranging from 2mm to 3000mm. Screw customization allows for a wide range of size options to meet specific requirements in various industries. When selecting the size of a custom screw, it is crucial to consider the application and the specific needs of the project. The table below illustrates some common size options available for custom screws.

| Diameter (mm) | Length (mm) | Common Application |

|---|---|---|

| M1 | 2 | Electronics |

| M10 | 50 | Automotive |

| M50 | 1000 | Construction |

The choice of size depends on factors such as load-bearing capacity, space constraints, and the desired level of stability. It is essential to consult with experts during the screw customization process to ensure that the selected size aligns with the material selection and manufacturing process.

4.3 Standard

Standard specifications play a crucial role in guiding the options available for custom screw manufacturing. When it comes to fastener customization, it is essential to consider the various standards that govern the screw manufacturing process. Here are three key aspects to consider regarding standardization in custom screw options:

- Global screw production: Standards such as GB, DIN, ASME, ASTM, ANSI, BS, EN, ISO, and JIS provide a universal framework for screw production, ensuring consistency and interoperability on a global scale.

- Quality assurance: Adhering to standard specifications guarantees the quality and reliability of custom screws, assuring customers that the products meet industry requirements.

- Material compatibility: Standards outline the materials suitable for screw manufacturing, ensuring that custom screws are designed using materials that are appropriate for the intended application.

4.4 Finishing

To ensure the desired appearance and durability of custom screws, a variety of finishing options are available, offering protection against corrosion and enhancing the overall aesthetic value of the fasteners.

Finishing techniques such as plating, black oxide, Xylan, Dacromet, Geomet, Nyloc, phosphating, and polish can be applied to custom screws to provide different levels of corrosion resistance and surface coatings.

Plating options include electro galvanizing, hot dip galvanizing, nickel, Zn-Ni, chrome, copper, gold, and silver. Black oxide is a popular choice for its dark and corrosion-resistant finish, while Xylan and Dacromet offer enhanced durability and corrosion protection.

Geomet and Nyloc coatings provide specialized benefits for specific applications.

The finishing process ensures that custom screws not only meet functional requirements but also maintain their visual appeal and longevity.

4.5 Head type

Featuring a range of head types, custom screws offer versatile options for various applications and fastening requirements. The head type plays a crucial role in the overall fastener design, determining the drive type and point type that can be used.

Here are the key head types commonly found in custom screws:

- Hexagon head: Provides a secure grip for easy installation and removal.

- Pan head: Offers a low-profile design for flush fastening and a wide bearing surface.

- Countersunk head: Enables the screw to sit flush with the surface, preventing snagging or accidental contact.

- Truss head: Designed for applications requiring high torque and load-bearing capacity.

- Flat head: Provides a flush finish and is commonly used in woodworking projects.

- Oval head: Offers a decorative appearance and is often used in furniture assembly.

Selecting the right head type ensures optimal performance and enhances the aesthetic appeal of the fastened material.

4.6 Drive type

The drive type is a crucial aspect to consider when selecting custom screws, building upon the various head types discussed previously. The drive type determines the tool required to install or remove the screw, and it plays a significant role in the functionality and security of the fastening application.

Common drive types in custom screws include Phillip/Cross, Slot, Inner hexagon, Pozi, Torx/Six lobes, and Square. Each drive type has its pros and cons, such as ease of use, resistance to stripping, and torque transfer capabilities.

Innovations in drive types for custom screws have led to advancements like tamper-resistant drives and one-way drives, providing additional security and preventing unauthorized removal.

Consideration of the benefits and drawbacks of different drive types is essential to ensure the optimal performance and reliability of custom screws in various applications.

4.7 Point type

When selecting custom screws, it is important to consider the point type, as it is a crucial factor in determining the fastening application's effectiveness and reliability. There are various types of point designs available, each suited for specific applications and offering unique advantages. The manufacturing process for custom screw points involves precision machining to ensure accurate dimensions and sharpness.

Some common point types include:

- Sharp point: Ideal for starting holes and penetrating materials easily.

- Blunt point: Provides better resistance to stripping and damage to the fastened material.

- Drill point: Designed for drilling through thin materials without the need for pre-drilling.

Understanding the different point types and their applications allows for better control over the fastening process, resulting in efficient and secure connections.

Manufacturers ensure high-quality point designs through advanced machining techniques and strict quality control measures.

Frequently Asked Questions

What Are the Common Materials Used in Custom Screw Manufacturing?

Stainless steel, titanium, brass, and aluminum are commonly used materials in custom screw manufacturing. These materials offer durability, strength, and corrosion resistance, making them suitable for various applications that require precision and control.

How Long Does It Typically Take to Manufacture a Custom Screw?

The manufacturing timeline for custom screws can vary depending on factors such as complexity and quantity. The production process typically involves design, material selection, machining, and quality control. Lead times can range from days to weeks, ensuring high-quality products.

Can Custom Screws Be Produced in Non-Standard Sizes or Shapes?

Custom screws can be produced in non-standard sizes and shapes through custom screw customization. This allows for unique screw designs and specialized screw production to meet the specific needs and dimensions required by the customer.

What Industries Commonly Require the Use of Custom Screws?

Various industries, such as aerospace, automotive, and construction, commonly require the use of custom screws due to their specific needs and requirements. The benefits of custom screws include improved performance, enhanced durability, and increased efficiency. However, customization options for screws may result in higher production costs, requiring careful consideration.

Are There Any Specific Regulations or Standards That Apply to Custom Screw Manufacturing?

Regulations overview for custom screw manufacturing include quality control measures, safety considerations, and environmental impact. These standards ensure the production of reliable and safe screws while minimizing any negative effects on the environment.

Mikehardware-your trusted custom lead screw manufacturer

In conclusion, custom screw manufacturing is a complex process that involves various steps and options.

It is interesting to note that China is the largest manufacturer of screws, producing over 60 billion screws annually. This statistic highlights the country's significant contribution to the global screw industry.

With the availability of custom options, businesses can find the perfect screws to meet their specific needs and requirements.

At Dongguan Mike Hardware Co., Ltd., precision engineering meets innovation, delivering impeccable CNC product manufacturing solutions. Explore our array of customized fasteners, screws, and coatings, ensuring your projects excel in performance, precision, and quality.

Elevate your engineering prowess with our tailored solutions—partner with us at Dongguan Mike Hardware Co., Ltd. for the pinnacle of CNC product excellence.