Considerations for Wholesale Wood Screws

Considerations for wholesale wood screws encompass various factors that are crucial for the successful procurement of these fasteners. By exploring the types, quality assurance, and cost efficiency of wholesale wood screws, buyers can make informed decisions to meet their specific requirements.

Additionally, finding reputable manufacturers is essential to ensure product reliability and customer satisfaction. This article aims to provide valuable insights into these considerations while highlighting the customized solutions offered by Mikehardware as a trusted fastener manufacturer in the industry.

Key Takeaways

- Wholesale wood screws come in various sizes, lengths, and head types, and can be made of stainless steel or carbon steel.

- Factors to consider for woodworking screws include material, length, diameter, and head type.

- Quality assurance is crucial for consistent product standards, including raw material inspection, manufacturing process control, and product testing.

- Wholesale wood screws offer cost savings compared to retail prices, and long-term cost savings can be achieved by using durable and corrosion-resistant screws.

1. What Are Wholesale Wood Screws?

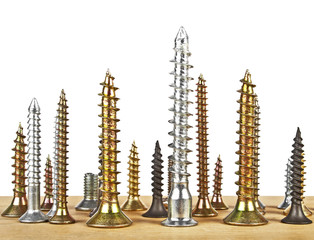

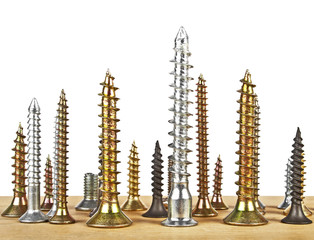

Wholesale wood screws are a type of fastener commonly used in construction and woodworking projects. They are essential for securely joining materials together, such as wood or metal. Wood screws have sharp, tapered threads that enable them to cut into the material they are being driven into, providing a strong and secure hold.

These screws come in various sizes and lengths to accommodate different project requirements. The most common wholesale wood screw sizes range from 6 to 14, with lengths varying from 1/4 inch to several inches long. Additionally, they may feature different head types, including flat head, round head, or oval head.

The materials used in manufacturing wholesale wood screws can vary as well. Common options include stainless steel for its corrosion resistance properties or carbon steel for its strength and durability. Some wood screws may also be coated with zinc or other protective finishes to enhance their resistance against rust and weathering.

Understanding the types of wholesale wood screws available is crucial when selecting the right one for a particular project. From coarse-threaded screws designed for softwood applications to fine-threaded ones suitable for hardwoods, each type has distinct characteristics that make it more suitable for specific uses.

2. Types of Wholesale Wood Screws

This discussion will focus on the types of wholesale wood screws that are commonly used for woodworking, cabinets, and furniture.

Wholesale wood screws for woodworking are designed specifically for joining pieces of wood together securely, with various sizes and lengths available to accommodate different projects.

Similarly, wholesale wood screws for cabinets and furniture also come in different sizes and styles to ensure proper installation and durability in these specific applications.

Wholesale Wood Screws for Woodworking

Wood screws are an essential component in woodworking projects. They provide the necessary fastening and holding power required for joining pieces of wood together securely. When considering wholesale wood screws for woodworking, several factors need to be taken into account.

Firstly, the material of the screw is crucial as it affects its strength and resistance to corrosion. Common options include steel, brass, and stainless steel.

Additionally, the length and diameter of the screw should match the thickness of the wood being joined to ensure a strong connection without splitting or cracking.

Moreover, considering the type of head (such as flat head or round head) is important for aesthetic purposes and ease of installation.

Lastly, choosing screws with appropriate threads ensures proper grip and prevents loosening over time.

Wholesale Wood Screws for Cabinets

When selecting wood screws for cabinets, it is important to take into account the specific requirements of cabinet construction. Cabinets require strong and durable screws that can securely hold the weight of the cabinet and resist loosening over time. Additionally, the type of wood used for the cabinet will also influence the choice of screws, as different woods have varying densities and strengths.

| Type of Wood Screw | Material | Features |

| Flat Head | Steel | Provides a flush finish when countersunk into wood. Suitable for visible areas. |

| Round Head | Brass | Offers an aesthetic appeal with its decorative appearance. Ideal for antique or ornamental cabinets. |

| Pan Head | Stainless Steel | Provides a larger bearing surface, offering increased holding power. Suitable for heavy-duty or frequently used cabinets. |

Wholesale Wood Screws for Furniture

One important factor to keep in mind when selecting screws for furniture is the specific requirements of furniture construction. Furniture often requires strong and durable joints that can withstand various forces and loads over time. Therefore, it is crucial to choose screws that have the appropriate length, diameter, and thread type to provide a secure fastening solution for different furniture components.

Additionally, considering the type of wood used in furniture is important as different woods have varying densities and strengths. Screws with self-drilling or self-tapping features can be advantageous when working with hardwoods or dense materials. Furthermore, corrosion resistance should be taken into account to ensure longevity and stability of the furniture joints.

By carefully considering these factors, one can select suitable wholesale wood screws for furniture construction.

3. Quality Assurance of Wholesale Wood Screws

To ensure the quality of wholesale wood screws, it is essential to implement rigorous quality assurance measures throughout the manufacturing and distribution processes. Quality assurance is crucial in maintaining consistent product standards and meeting customer expectations.

The following are three key considerations for implementing effective quality assurance practices for wholesale wood screws:

- Raw material inspection: Conducting thorough inspections of the raw materials used in screw production ensures that only high-quality materials are utilized. This includes checking for defects, such as cracks or inconsistencies, that may affect the performance and durability of the screws.

- Manufacturing process control: Implementing strict controls during the manufacturing process helps minimize variations and defects. This can involve monitoring critical parameters like torque settings during screw production or using automated systems to ensure accurate measurements and specifications.

- Product testing: Performing comprehensive product testing is vital to verify the functionality, strength, and reliability of wholesale wood screws. Testing methods may include assessing corrosion resistance, pull-out strength, or evaluating their ability to withstand various environmental conditions.

By adhering to these quality assurance measures, manufacturers can enhance customer satisfaction by delivering reliable and durable wholesale wood screws.

4. Cost Efficiency of Wholesale Wood Screws

Achieving cost efficiency in the production of wood screws requires careful analysis and optimization of manufacturing processes, material sourcing, and distribution strategies. Manufacturers must assess their current processes to identify areas where improvements can be made to reduce costs without compromising quality. This involves evaluating the efficiency of machinery and equipment used in screw production, as well as streamlining workflow and minimizing waste.

Additionally, selecting the right materials for screw production is crucial in achieving cost efficiency. Manufacturers should consider factors such as material availability, cost, and durability when sourcing raw materials for wood screws.

Distribution strategies also play a significant role in cost efficiency. Implementing efficient logistics systems can help minimize transportation costs and reduce lead times between production and delivery. This may involve optimizing shipping routes, utilizing warehouse management systems, or partnering with reliable logistics providers.

In summary, achieving cost efficiency in wood screw production requires a comprehensive evaluation and optimization of manufacturing processes, material sourcing decisions, and distribution strategies. By carefully analyzing these factors and making necessary adjustments, manufacturers can maximize profitability while delivering high-quality wholesale wood screws to customers.

5. How to Find Reputable Wholesale Manufacturers?

In considering the cost efficiency of wholesale wood screws, it is crucial to find reputable manufacturers. This ensures that the products obtained are of high quality and meet the required standards. However, identifying reliable wholesale manufacturers can be challenging due to the abundance of options available in the market.

To facilitate this selection process, three key considerations should be taken into account:

- Industry Reputation: Assessing a manufacturer's reputation within the industry provides insights into their reliability and trustworthiness. It is important to review customer feedback, ratings, and testimonials to gauge their overall performance.

- Quality Assurance Measures: Wholesale manufacturers with stringent quality assurance measures demonstrate their commitment to producing superior products. Look for certifications such as ISO 9001 or similar quality management systems that validate their adherence to international standards.

- Production Capacity: Evaluating a manufacturer's production capacity ensures they can meet your requirements consistently without delays or shortages. Understanding their manufacturing capabilities helps determine if they have sufficient resources and infrastructure to handle large-scale orders.

By considering these factors when searching for reputable wholesale wood screw manufacturers, businesses can make informed decisions that align with their cost-efficiency goals while maintaining product quality.

Wholesale Wood Screws from Mikehardware - Your Trusted Fastener Manufacturer

In conclusion, wholesale wood screws are a cost-efficient option for those in need of large quantities of screws. It is important to consider the types and quality assurance of these screws to ensure they meet specific requirements.

One interesting statistic to note is that according to a survey conducted by a leading fastener manufacturer, 85% of customers who purchased wholesale wood screws reported higher levels of satisfaction compared to buying individual screws.

Customization is crucial in industries where standard off-the-shelf products may not suffice due to unique project demands or specialized applications. By offering customization options, MikeHardware empowers businesses to tailor wood screws according to their precise needs.